Polyimide gas separation membrane as well as preparation method and applications thereof

A technology of gas separation membrane and polyimide, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of gas selectivity decline, achieve improved gas permeability, high permeability, and suppress tightness stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

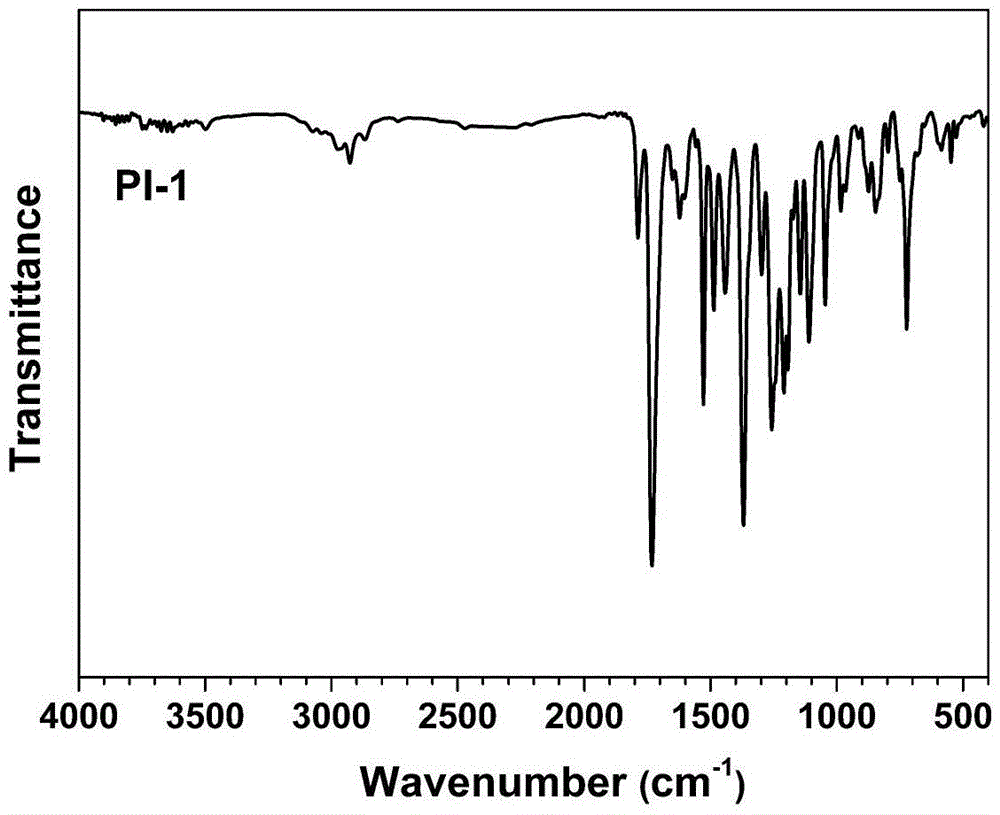

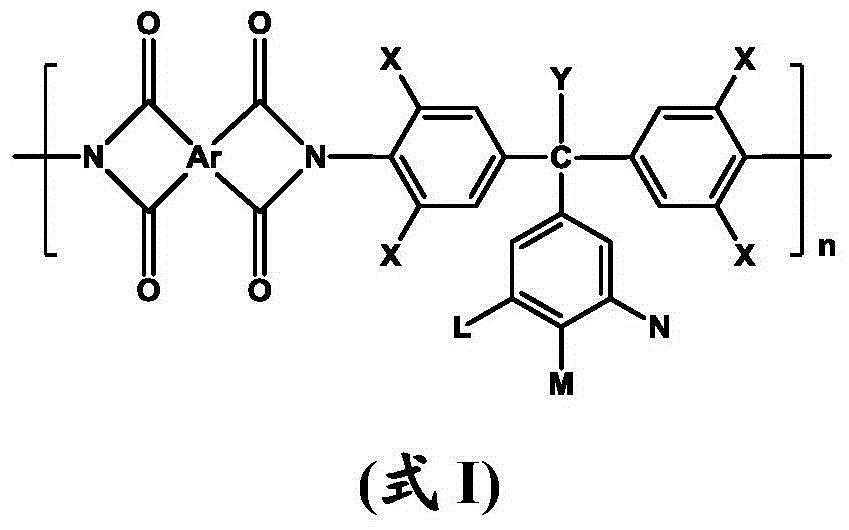

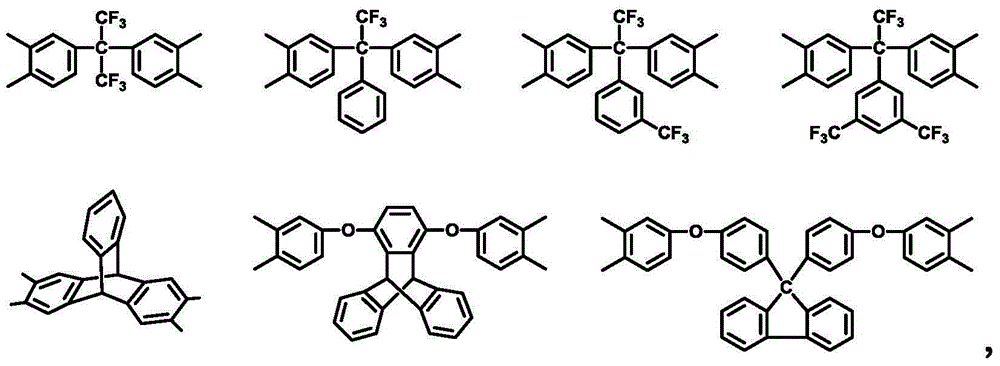

[0044] Embodiment 1, the preparation of polyimide gas separation membrane

[0045] In a three-necked flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 39.85 grams (0.1 mol) of α,α-bis(4-amino-3,5-dimethylphenyl)-1-( 4'-trifluoromethylphenyl) methane and N-methylpyrrolidone (NMP) 126 grams, stirred under nitrogen protection until completely dissolved, then added 44.42 grams (0.1 mole) 4,4'-(hexafluoroisopropyl Base) two phthalic anhydride (6FDA), to obtain a solid content of 40wt.% of the homogeneous solution. 0.65 g (0.005 mole) of isoquinoline and 21 g of toluene were added to the above homogeneous solution, the temperature of the reaction system was raised to 180° C. and reacted for 12 hours, the toluene was distilled off, and the heating was stopped. Cool the reaction solution to 80-120°C and pour it into methanol to obtain a fibrous crude product, collect the precipitated crude product, wash repeatedly with me...

Embodiment 2

[0049] Embodiment 2, the preparation of polyimide gas separation membrane

[0050] In a three-necked flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 34.85 grams (0.1 moles) of α,α-bis(4-amino-3,5-dimethylphenyl)-1-( 4'-fluorophenyl)methane and N,N-dimethylacetamide (DMAc) 147 grams, stirred under nitrogen protection until completely dissolved, then added 44.42 grams (0.1 mole) 4,4'-(hexafluoroiso Propyl) diphthalic anhydride (6FDA) to obtain a homogeneous solution with a solid content of 35wt.%. 1.29 grams (0.01 moles) of quinoline and 25 grams of xylene were added to the above homogeneous solution, the temperature of the reaction system was raised to 140° C. for 12 hours, the xylene was distilled off, and the heating was stopped. Cool the reaction solution to 80-120°C and pour it into ethanol to obtain a fibrous crude product, collect the precipitated crude product, wash repeatedly with ethanol and water, filte...

Embodiment 3

[0052] Embodiment 3, the preparation of polyimide gas separation membrane

[0053] In a three-necked flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 38.44 grams (0.1 mol) of α,α-bis(4-amino-3,5-dimethylphenyl)-1-( 3',4',5'-trifluorophenyl) methane and N-methylpyrrolidone (NMP) 154 grams, stirred under nitrogen protection until completely dissolved, then added 44.42 grams (0.1 mol) 4,4'-( Hexafluoroisopropyl) diphthalic anhydride (6FDA) to obtain a homogeneous solution with a solid content of 35wt.%. 1.29 grams (0.01 moles) of quinoline and 26 grams of toluene were added to the above-mentioned homogeneous solution, the temperature of the reaction system was raised to 180° C. and reacted for 10 hours, the toluene was distilled off, and the heating was stopped. Cool the reaction solution to 80-120°C and pour it into ethanol to obtain a fibrous crude product, collect the precipitated crude product, wash repeatedly w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com