A kind of preparation method of gas separation membrane with high MOF filler content

A gas separation membrane and filler content technology, applied in the field of membrane separation, can solve problems such as unsatisfactory mechanical properties and reduced separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

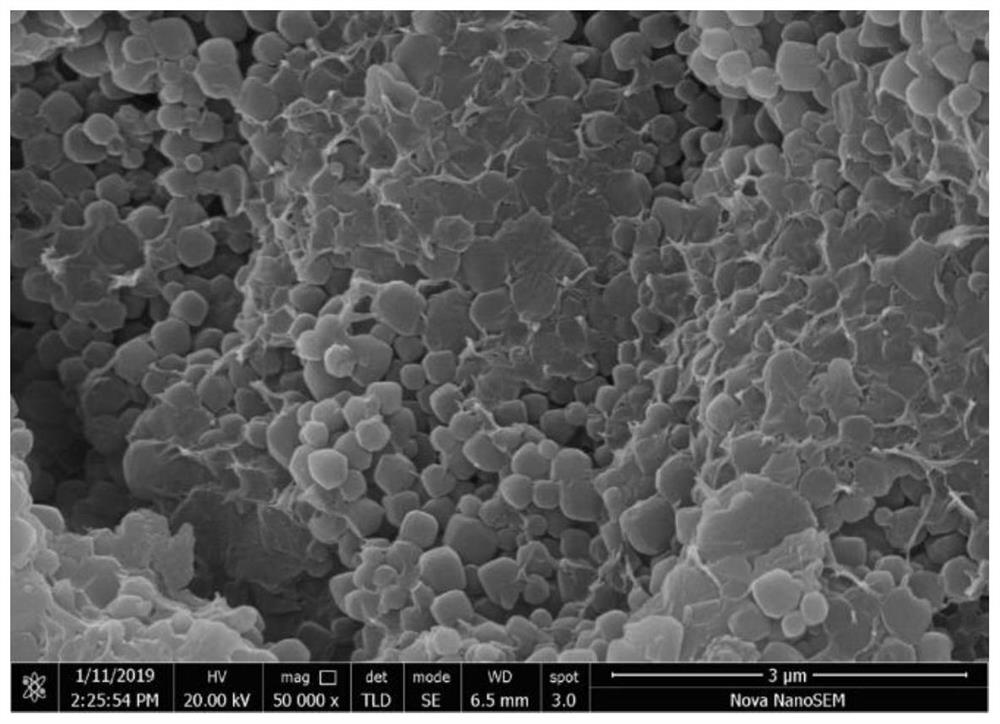

[0023] Add 0.5 g of the activated ZIF-8 powder into 20 mL of dichloromethane, and ultrasonicate the water bath for 30 minutes to completely disperse ZIF-8 in the dichloromethane. Add a certain amount of PVDF into dimethyl sulfoxide, stir to dissolve to prepare 7.5wt% membrane liquid. Take 3.33g of membrane solution and add it to the above-mentioned UiO-66 dispersion solution, and continue to sonicate for 60 minutes. The dichloromethane in the mixed solution is fully volatilized by stirring and volatilizing to obtain a viscous casting solution. Pour the prepared casting solution onto the prepared glass plate, scrape off a film with a thickness of 200 μm at a certain speed with a scraper, then put the glass plate into a preheated oven at 70°C, and wait until the dimethylmethylene After the sulfone volatilized, the prepared membrane was removed. Place the dried membrane on a PTFE plate Add 3g of Pebax 1657 solution prepared at 3wt% to the glass circle. Put the PTFE plate int...

Embodiment 2

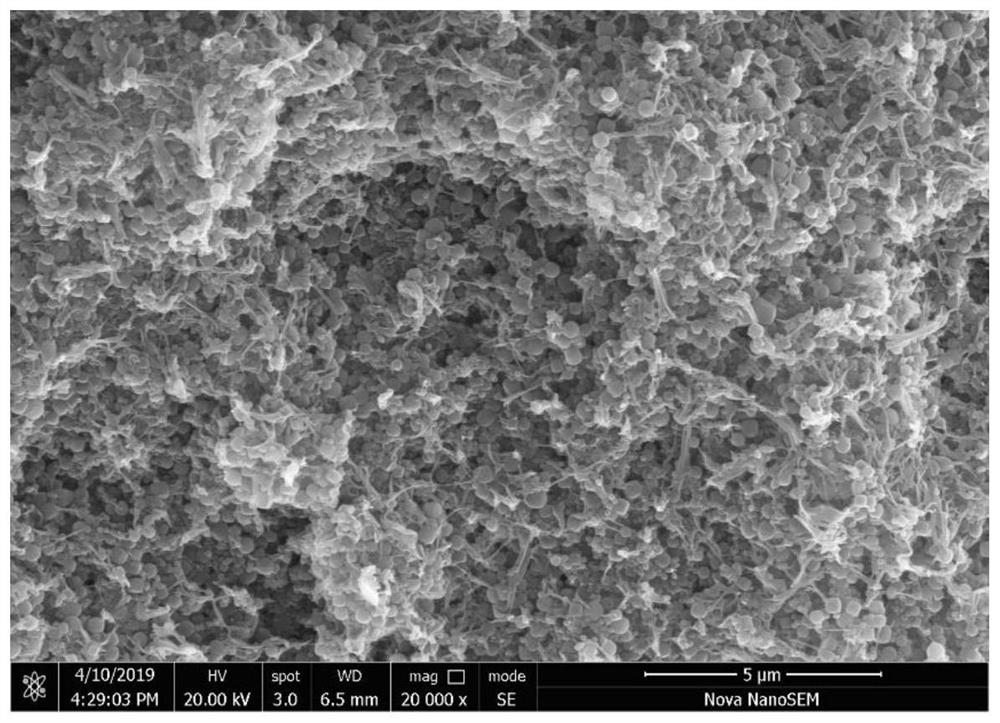

[0026] Add 0.6 g of activated UiO-66 powder into 30 mL of chloroform, and ultrasonicate the water bath for 30 minutes to completely disperse UiO-66 in chloroform. Add a certain amount of PEG600000 into water, stir to dissolve to prepare 8wt% membrane liquid. Take 3.25g of membrane solution and add it to the above UiO-66 dispersion, and continue to sonicate for 60 minutes. The chloroform in the mixed solution is fully volatilized by stirring and volatilizing to obtain a viscous casting solution. Pour the prepared casting solution onto the prepared glass plate, scrape out a film with a thickness of 250 μm at a certain speed with a scraper, then put the glass plate into a preheated oven at 70°C, wait until the DMF volatilizes and take it out. Prepared membranes. Place the dried membrane on a PTFE plate Add 4 g of a prepared 3 wt % polydimethylsiloxane solution to the glass ring. Put the PTFE plate into a preheated oven to remove the solvent to obtain a high MOF content gas s...

Embodiment 3

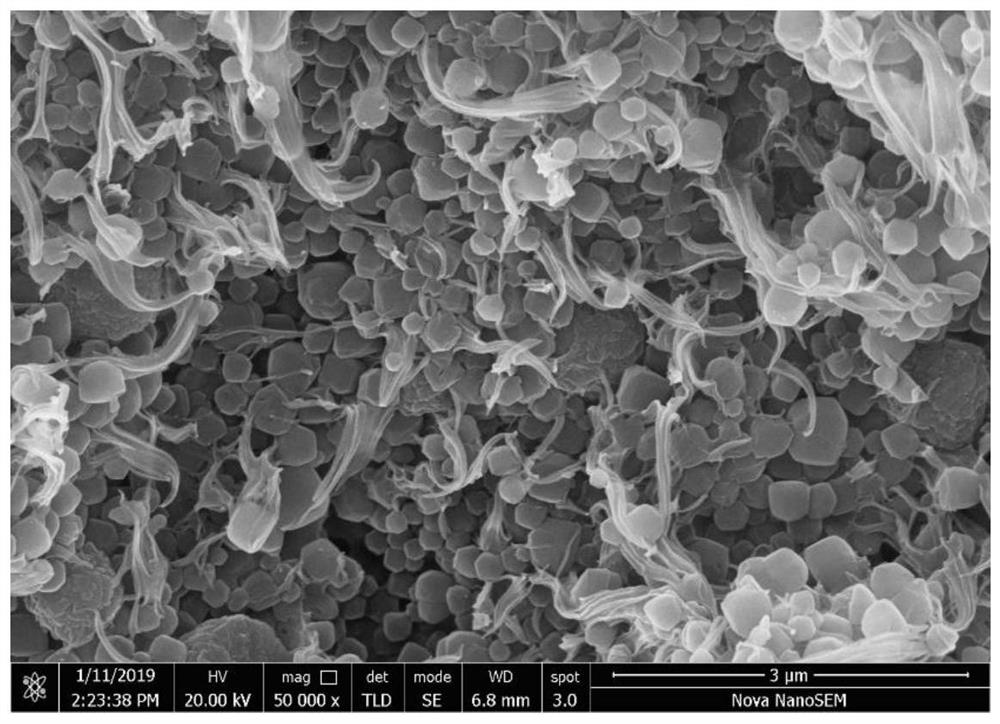

[0029] Add 0.5 g of activated UiO-66 powder into 20 mL of acetone, and ultrasonicate the water bath for 30 minutes to completely disperse UiO-66 in acetone. Add a certain amount of PVDF into DMF, stir to dissolve to prepare 7.5wt% membrane liquid. Take 1.3g of membrane solution and add it to the above-mentioned UiO-66 dispersion solution, and continue to sonicate for 60 minutes. The acetone in the mixed solution is fully volatilized by stirring and volatilizing to obtain a viscous casting solution. Pour the prepared casting solution onto the prepared glass plate, scrape a film with a thickness of 300 μm at a certain speed with a scraper, then put the glass plate into a preheated oven at 70°C, wait until the DMF volatilizes and take it out. Prepared membranes. Place the dried membrane on a PTFE plate Into the glass ring, add 4g of a prepared 3wt% polyetherimide solution. Put the PTFE plate into a preheated oven to remove the solvent to obtain a high MOF content gas separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com