Method for preparing CO2 separation membrane material and composite membrane

A technology for separating membranes and polymers, which is applied in separation methods, semipermeable membrane separations, and dispersed particle separations. It can solve the problems of reduced polymer screening ability and difficulty in improving gas separation performance, and achieves improved plasticization resistance. , Improve membrane dissolution selectivity and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

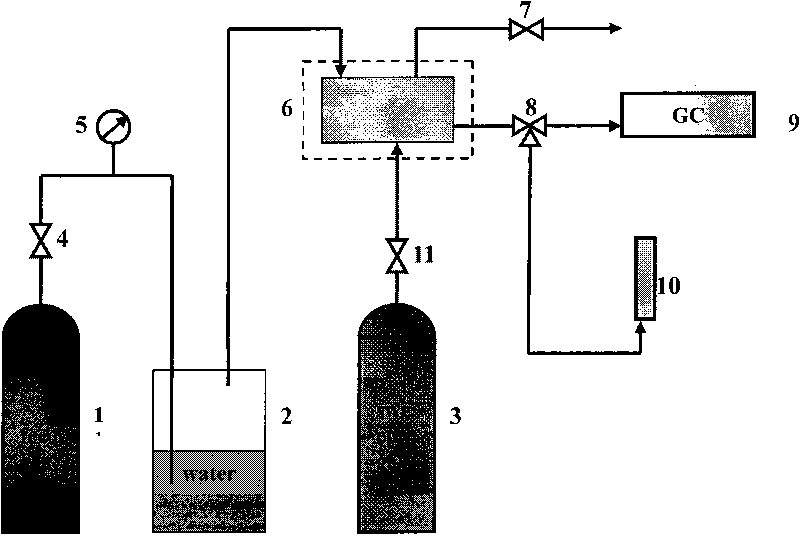

Method used

Image

Examples

Embodiment 1

[0036]Take 4g of DMAEMA and 1g of PEGMEMA (molecular weight 130) and add them to about 10g of THF, add 0.1% initiator AIBN of the total mass, pass through nitrogen to remove oxygen in the solution, then heat to 80°C for reflux reaction for 24h, pour the solution after cooling Precipitate in petroleum ether under stirring to obtain a white polymer, then put it in a vacuum oven and bake at 80°C for 24 hours to obtain a light yellow and transparent polymer PDMAEMA-PEGMEMA, take 0.5g of PDMAEMA-PEGMEA and dissolve it in 20ml of ethanol, then Take 0.223XDC (xylene dichloride) as a cross-linking agent and dissolve it in 15ml of ethanol, then mix the two solutions, ultrasonicate for 10min; pour (submerge) on the polysulfone plate bottom membrane treated with ethanol, then pour out the solution at room temperature Dry, repeat twice, and finally dry at room temperature for 24 hours.

[0037] Test gas separation performance:

[0038] J CO2 / l=20×10 -6 cm 3 (STP). / cm 2 .s.cmHg

[0...

Embodiment 2

[0041] Take 3g of DMAEMA and 7g of PEGMEMA (molecular weight: 530) and add them to about 20g of THF, add 0.1% initiator AIBN of the total mass, pass through nitrogen to remove oxygen in the solution, then heat to 80°C for reflux reaction for 24h, pour the solution after cooling Precipitate in petroleum ether under stirring to obtain a white polymer, and then put it in a vacuum oven at 80°C for 24 hours to obtain a light yellow and transparent polymer PDMAEMA-PEGMEMA. Take 0.5g of PDMAEMA-PEGMEA and dissolve it in 20ml of ethanol, and then take Dissolve 0.0835g XDC (xylene dichloride) in 15ml ethanol as a cross-linking agent, then mix the two solutions, sonicate for 10min, and pour it on the bottom film of the polysulfone flat plate treated with ethanol, then pour off the solution and dry it at room temperature, repeat 2 times, and finally dry at room temperature for 24 hours.

[0042] Test gas separation performance:

[0043] J CO2 / l=80×10 -6 cm 3 (STP). / cm 2 .s.cmHg

...

Embodiment 3

[0046] Take 1g of DMAEMA and 9g of PEGMEMA (molecular weight 530) and add it to about 20g of THF, add 0.1% initiator AIBN of the total mass, feed nitrogen to remove oxygen in the solution, then heat to 80°C for reflux reaction for 24h, pour the solution after cooling Precipitate in petroleum ether under stirring to obtain a white polymer, and then put it in a vacuum oven at 80°C for 24 hours to obtain a light yellow and transparent polymer PDMAEMA-PEGMEMA. Take 0.5g of PDMAEMA-PEGMEA and dissolve it in 20ml of ethanol, and then take 0.0278 gXDC (xylene dichloride) was dissolved in 15ml of ethanol as a cross-linking agent, then the two solutions were mixed, ultrasonicated for 10 minutes, poured (submerged) on the polysulfone plate base film treated with ethanol, and then poured out the solution and dried at room temperature. Repeat 2 times, and finally dry at room temperature for 24 hours.

[0047] Test gas separation performance:

[0048] J CO2 / l=110×10 -6 cm 3 (STP). / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com