Supported composite carbon molecular sieve membrane

A composite carbon and molecular sieve technology, applied in the field of membrane separation, can solve the problems of limited industrial application, low permeability and high brittleness of carbon molecular sieve membrane, and achieve the effect of improving mechanical properties, excellent gas separation performance and high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of microporous material ZIF-108:

[0051] Weigh 0.318 gram of zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) was dissolved in 16 ml of nitrogen, nitrogen-dimethylformamide (DMF), and 0.328 g of 2-nitroimidazole (nim) was dissolved in 40 ml of nitrogen, nitrogen-dimethylformamide. Add the former to the latter and mix at room temperature for 2.5 hours. After the reaction is completed, centrifuge and wash with 20 ml of nitrogen, nitrogen-dimethylformamide ultrasonically for 15 minutes each time, and the product is ready for use.

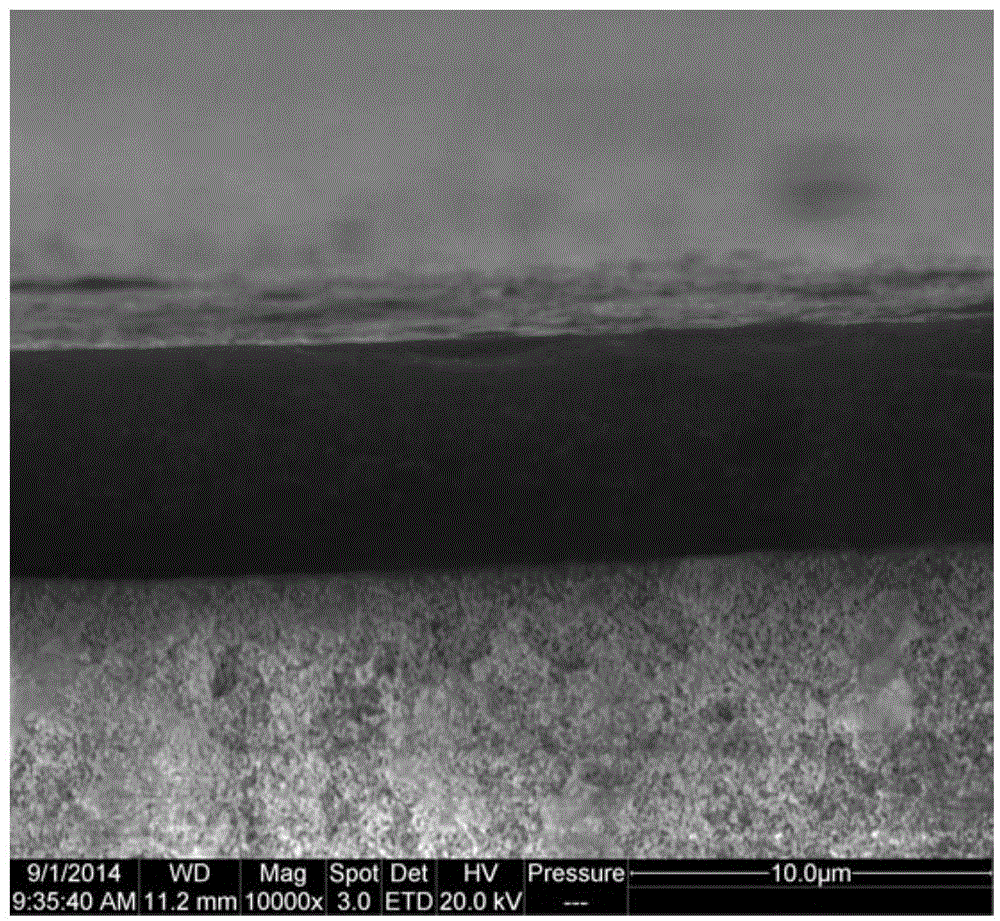

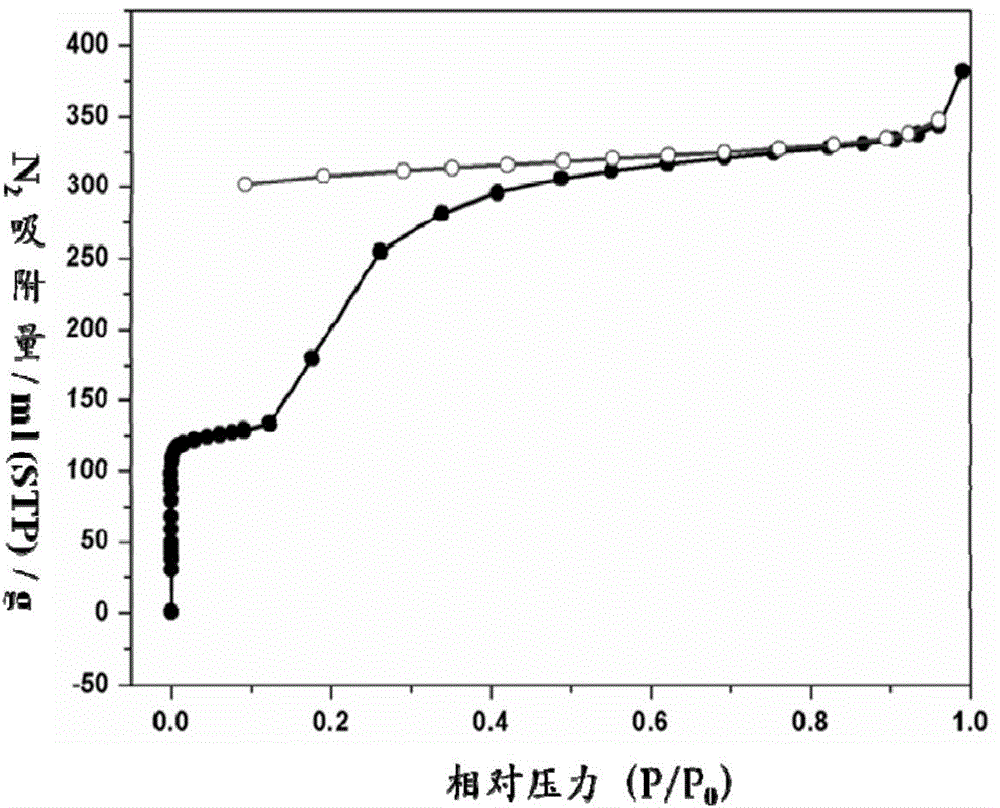

[0052] X-ray diffraction detection product: with regular crystal form (such as figure 1 ), respectively, the scanning electron microscope pictures show that the product has a uniform morphology (such as figure 2 ), the particle size is nanoscale. N 2 Adsorption experiments proved that the material has a microporous structure ( image 3 ), its specific surface area is 1371m 2 / g.

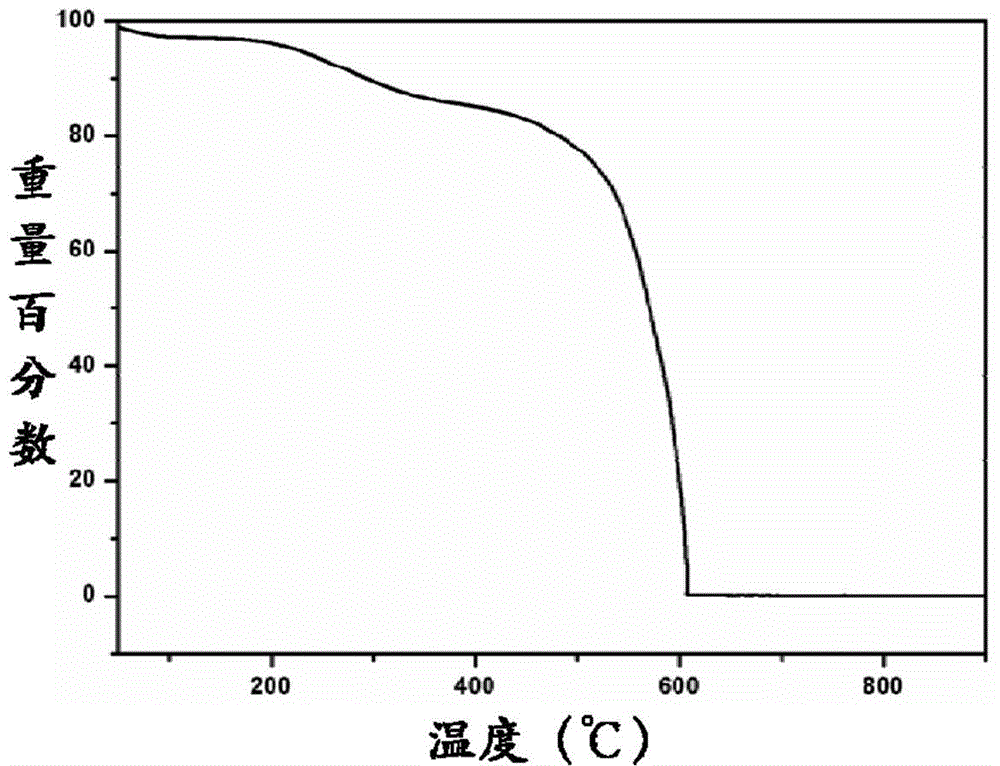

[0053] Thermogravimetric analysis experiments p...

Embodiment 2

[0070] 1. Prepare the carbon molecular sieve membrane product D according to steps 2 to 4 in the preparation method of the product A in Example 1, wherein the method for preparing the film-forming raw material in the step 2 is:

[0071] Weigh directly 1.1916 grams of polymer P84, press W P84 :W DMF =1:12.7 ratio Add 15.0835 g of DMF to prepare polymer solution, stir for 24 hours, where W represents mass.

[0072] 2. Permeability and selectivity are two important indicators to evaluate the gas separation performance of the membrane, and the permeability (P i ) and separation coefficient (α ij ) to represent. Permeability P i =J i / A*ΔP, where J i is the permeation flow rate of the gas, unit molm -2 the s -1 , A is the effective membrane area, unit m 2 , ΔP is the pressure difference on both sides of the membrane, unit Pa; separation coefficient α ij =P i / P j , where P i is the permeability of gas i, P j is the permeability of gas j. The gas permeability of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com