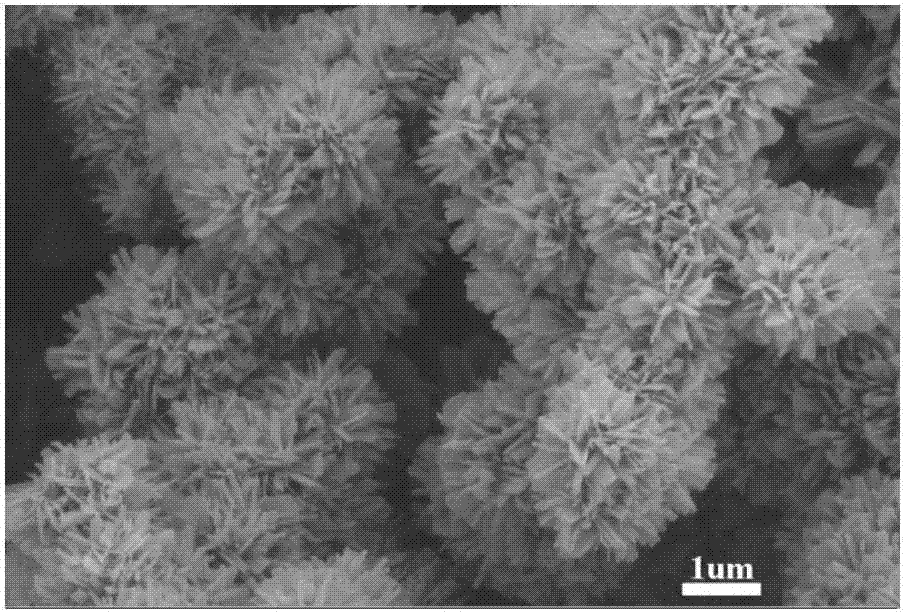

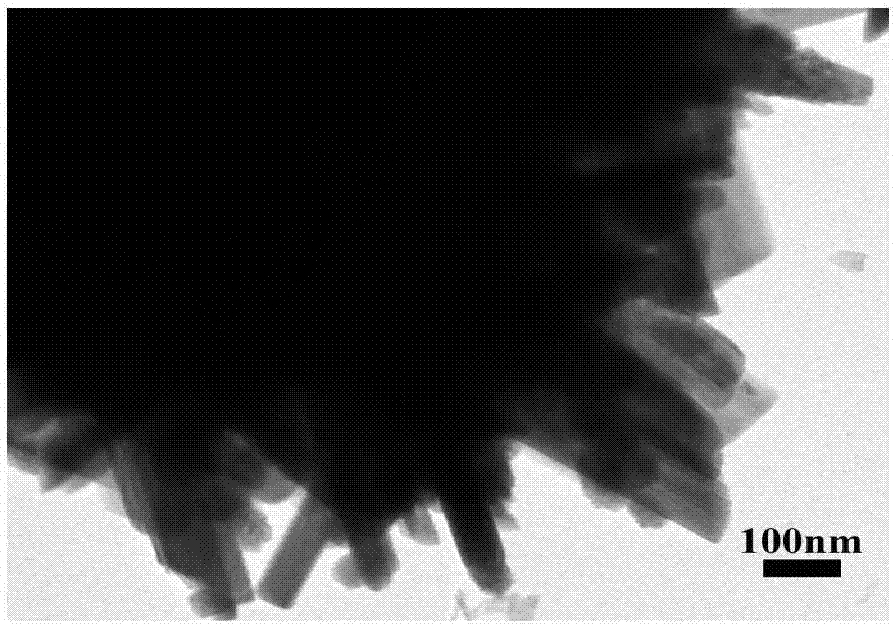

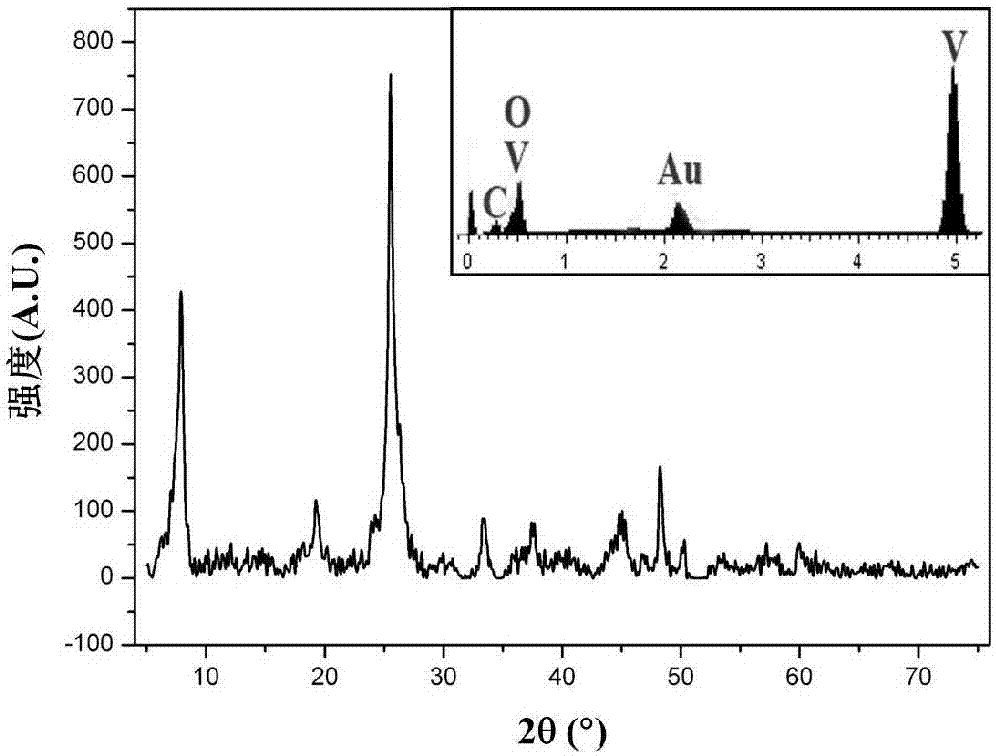

Preparation method and application of a sea urchin-like vanadium-based nano-electrode material

A nano-electrode and sea urchin-like technology, which is applied in the field of preparation of sea urchin-like vanadium-based nano-electrode materials, can solve the problems of soft template removal, achieve good controllability, and improve the effect of mechanical strength and crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: one, a kind of preparation method of sea urchin shape vanadium-based nano-electrode material, comprises the steps:

[0035] 1) Add 4mmolV 2 o 5 (purity is 99%) join 32.64mL mass concentration and be 10% H 2 o 2 Solution, in 25 ℃ water bath electromagnetic stirring 2h, obtains transparent bright red vanadium precursor solution (V V ); Wherein, mass concentration is 10% hydrogen peroxide solution and adopts 10.88mL mass concentration to be 30% H 2 o 2 Solution mixed with 21.76mL deionized water;

[0036] 2) Measure 6mL of vanadium precursor solution into a 50mL beaker, then add 17mL of ethylene glycol (EG) and 17mL of deionized water, and finally add 3mmol of (NH 4 ) 2 SO 4 , magnetic stirring for 10min to mix the solution (the pH of the mixed solution is 2.5);

[0037] 3) After the stirring is completed, transfer the solution to a 50mL hydrothermal reaction kettle, seal it and put it in a dry box for a hydrothermal reaction at 180°C for 24 hours, a...

Embodiment 2

[0046] Embodiment 2: one, a kind of preparation method of sea urchin shape vanadium-based nano-electrode material, comprises the steps:

[0047] 1) Add 4mmolV 2 o 5 (purity is 99%) join 32.64mL mass concentration and be 10% H 2 o 2 Solution, in 25 ℃ water bath electromagnetic stirring 2h, obtains transparent bright red vanadium precursor solution (V V ); Wherein, mass concentration is 10% hydrogen peroxide solution and adopts 10.88mL mass concentration to be 30% H 2 o 2 Solution mixed with 21.76mL deionized water;

[0048] 2) Measure 5mL of vanadium precursor solution into a beaker, then add 15mL of ethylene glycol (EG) and 20mL of deionized water, and finally add 3mmol of (NH 4 ) 2 SO 4 , magnetic stirring for 10min to mix the solution (the pH of the solution is 2.5);

[0049] 3) After the stirring is completed, transfer the solution to a hydrothermal reaction kettle, seal it and put it in a dry box for hydrothermal reaction at 200°C for 24 hours, and air cool to roo...

Embodiment 3

[0058] Embodiment 3: one, a kind of preparation method of sea urchin shape vanadium-based nano-electrode material, comprises the steps:

[0059] 1) Add 4mmolV 2 o 5 (purity is 99%) join 32.64mL mass concentration and be 20% H 2 o 2 Solution, in 25 ℃ water bath electromagnetic stirring 2h, obtains transparent bright red vanadium precursor solution (V V); Wherein, mass concentration is 20% hydrogen peroxide solution and adopts 21.76mL mass concentration to be 30% H 2 o 2 Solution mixed with 10.88mL deionized water;

[0060] 2) Measure 6mL of vanadium precursor solution into the beaker, then add 17mL of ethylene glycol (EG) and 17mL of deionized water, and finally add 5mmol of (NH 4 ) 2 SO 4 , adjust the pH of the solution to 2.0 with 1M dilute sulfuric acid, and stir the solution for 10 minutes with electromagnetic stirring;

[0061] 3) After the stirring is completed, transfer the solution to a hydrothermal reaction kettle, seal it and put it in a dry box for hydrother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com