A kind of graphene/polypyrrole particle composite gel film and preparation method thereof

A pyrrole particle and composite gel technology, which is applied in the field of graphene/polypyrrole particle composite gel film and its preparation, can solve the problems of poor water dispersibility of polypyrrole and difficulty in preparing graphene/polypyrrole particle composite film, etc. , to achieve the effect of easy uniform distribution, simple and reliable process method, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

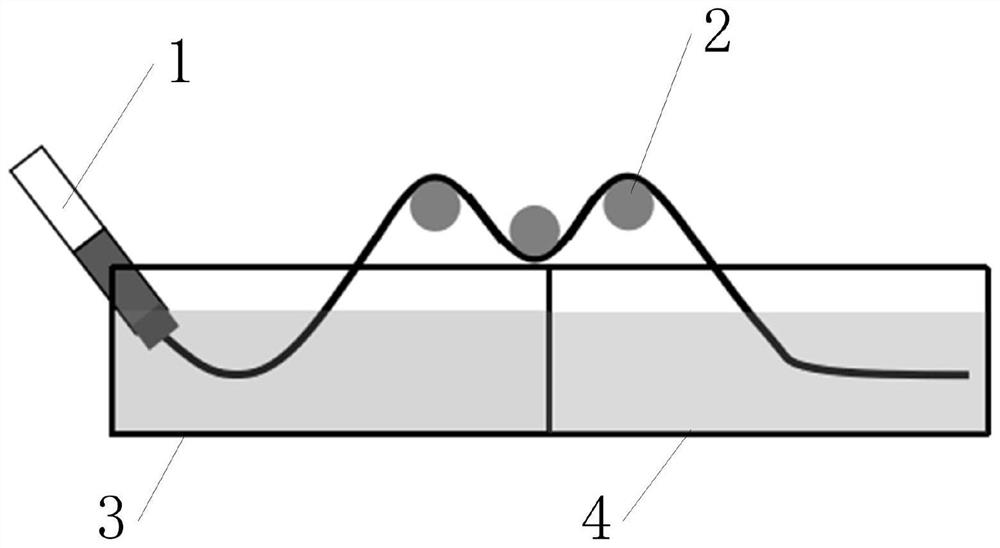

[0038] See Figure 1 , Figure 1 Schematic diagram of the preparation process flow of graphene / polypyrrole particle composite gel film in the present embodiment.

[0039] The preparation method of graphene / polypyrrole particle composite gel film provided in the present embodiment is as follows:

[0040] S1: Mix pyrrole with hydrochloric acid solution in gel pool 3 to form gel pool solution;

[0041] S2: The graphene oxide is mixed evenly with the high oxide valence metal oxide particle dispersion to form a graphene oxide / high oxidation valence metal oxide mixed dispersion, and the graphene oxide / high oxidation valence metal oxide mixed dispersion is added to the feed container;

[0042] S3: Using fluid transfer machinery 1, the graphene oxide / high oxidation valence metal oxide mixed dispersion in step S2 is squeezed into the gel pool 3 through the nozzle connected to the fluid transport machinery 1, and the graphene oxide / high oxidation valence metal oxide mixed dispersi...

Embodiment 2

[0055] The graphene / polypyrrole particle composite gel thin film preparation method provided in the present embodiment steps are as follows:

[0056] S1: Mix pyrrole with hydrochloric acid solution in gel pool 3 to form a gel pool solution, where the gel pool solution volume is 200mL, the pyrrole content in the gel pool solution is 0.1vol, and the hydrochloric acid concentration is 1mol / L;

[0057] S2: The graphene oxide dispersion with a concentration of 5mg / mL and the manganese oxide particle dispersion with a concentration of 5mg / mL at 1mL are vigorously stirred or shaken for 2min, so that it is mixed evenly to form a mixed dispersion of graphene oxide / manganese oxide, and the graphene oxide / manganese oxide mixed dispersion is added to the feed container, and the particle size of the manganese oxide particles in this step is 20nm;

[0058]S3: Using a syringe pump, the graphene oxide / manganese oxide mixed dispersion is squeezed into the gel pool through a nozzle connected to...

Embodiment 3

[0071] The graphene / polypyrrole particle composite gel thin film preparation method provided in the present embodiment steps are as follows:

[0072] S1: Mix pyrrole with hydrochloric acid solution in gel pool 3 to form a gel pool solution, where the gel pool solution volume is 200 mL, the gel pool solution has 1vol, and the hydrochloric acid concentration is 1mol / L;

[0073] S2: The graphene oxide dispersion with a concentration of 2mL of 10mg / mL and the dispersion of iron oxide particles with a concentration of 20mg / mL of 1mL are violently stirred or shaken for 2min, so that it is mixed evenly to form a graphene oxide / iron oxide mixed dispersion, and the graphene oxide / iron oxide mixed dispersion is added to the feed container, and the particle size of the iron oxide particles in this step is 200nm;

[0074]S3: Using a turbocharged pump, the graphene oxide / iron oxide mixed dispersion is squeezed into the gel pool through the nozzle connected to the turbocharging pump, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com