Preparation of multifunctional graphene-based material and application of multifunctional graphene-based material in supercapacitor and water treatment

A graphene-based, ultrasonic technology, used in graphene, water/sewage treatment, hybrid capacitor electrodes, etc., can solve problems such as general electrochemical performance, achieve excellent performance, prevent agglomeration, and enhance the effect of enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

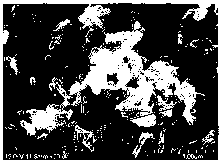

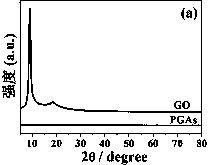

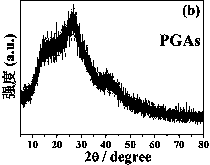

Image

Examples

Embodiment 1

[0030] (1) Sonicate 200 mg graphene oxide in 100 ml ultrapure water with an ultrasonic cell disruptor for 10 h to obtain a uniformly dispersed graphene oxide solution for use;

[0031] (2) Distill the pyrrole monomer solution under reduced pressure, vacuumize the combined device, wrap the whole device with tin foil to prevent the re-oxidation of the distilled pyrrole, and distill it in a hot water bath at 100°C under nitrogen to obtain fresh pyrrole Single stand-by;

[0032] (3) Add an appropriate amount of FeCl 3 ·6H 2 O was added to 10 ml deionized and ultrasonically dispersed into FeCl 3 ·6H 2 O is completely dissolved for use;

[0033] (4) Take 25 ml of polytetrafluoroethylene lining, add 5 ml of graphene oxide dispersion, and then add 0.5 ml of fresh pyrrole monomer, sonicate the mixed solution for 10 min in an ultrasonic cell disruptor to mix the two solutions evenly ready for use;

[0034] (5) Put the lining into the ultrasonic cleaner, and then put the FeCl 3 ·6...

Embodiment approach 2

[0039] (1) Sonicate 200 mg graphene oxide in 100 ml ultrapure water with an ultrasonic cell disruptor for 10 h to obtain a uniformly dispersed graphene oxide solution for use;

[0040] (2) Distill the pyrrole monomer solution under reduced pressure, vacuumize the combined device, wrap the whole device with tin foil to prevent the re-oxidation of the distilled pyrrole, and distill it in a hot water bath at 100°C under nitrogen to obtain fresh pyrrole Single stand-by;

[0041] (3) Add an appropriate amount of FeCl 3 ·6H 2 O was added to 10 ml deionized and ultrasonically dispersed into FeCl 3 ·6H 2 O is completely dissolved for use;

[0042] (4) Take 25 ml of polytetrafluoroethylene lining, add 5 ml of graphene oxide dispersion, and then add 0.5 ml of fresh pyrrole monomer, sonicate the mixed solution for 10 min in an ultrasonic cell disruptor to mix the two solutions evenly ready for use;

[0043] (5) Put the lining into the ultrasonic cleaner, and then put the FeCl 3 ·6...

Embodiment approach 3

[0048] (1) Sonicate 200 mg graphene oxide in 100 ml ultrapure water with an ultrasonic cell disruptor for 10 h to obtain a uniformly dispersed graphene oxide solution for use;

[0049] (2) Distill the pyrrole monomer solution under reduced pressure, vacuumize the combined device, wrap the whole device with tin foil to prevent the re-oxidation of the distilled pyrrole, and distill it in a hot water bath at 100°C under nitrogen to obtain fresh pyrrole Single stand-by;

[0050] (3) Add an appropriate amount of FeCl 3 ·6H 2 O was added to 10 ml deionized and ultrasonically dispersed into FeCl 3 ·6H 2 O is completely dissolved for use;

[0051] (4) Take 25 ml of polytetrafluoroethylene lining, add 5 ml of graphene oxide dispersion, and then add 0.5 ml of fresh pyrrole monomer, sonicate the mixed solution for 10 min in an ultrasonic cell disruptor to mix the two solutions evenly ready for use;

[0052] (5) Put the lining into the ultrasonic cleaner, and then put the FeCl 3 ·6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com