In-suit loaded type foam microporous precious metal catalyst, and preparation method thereof

A precious metal catalyst, supported technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. , to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

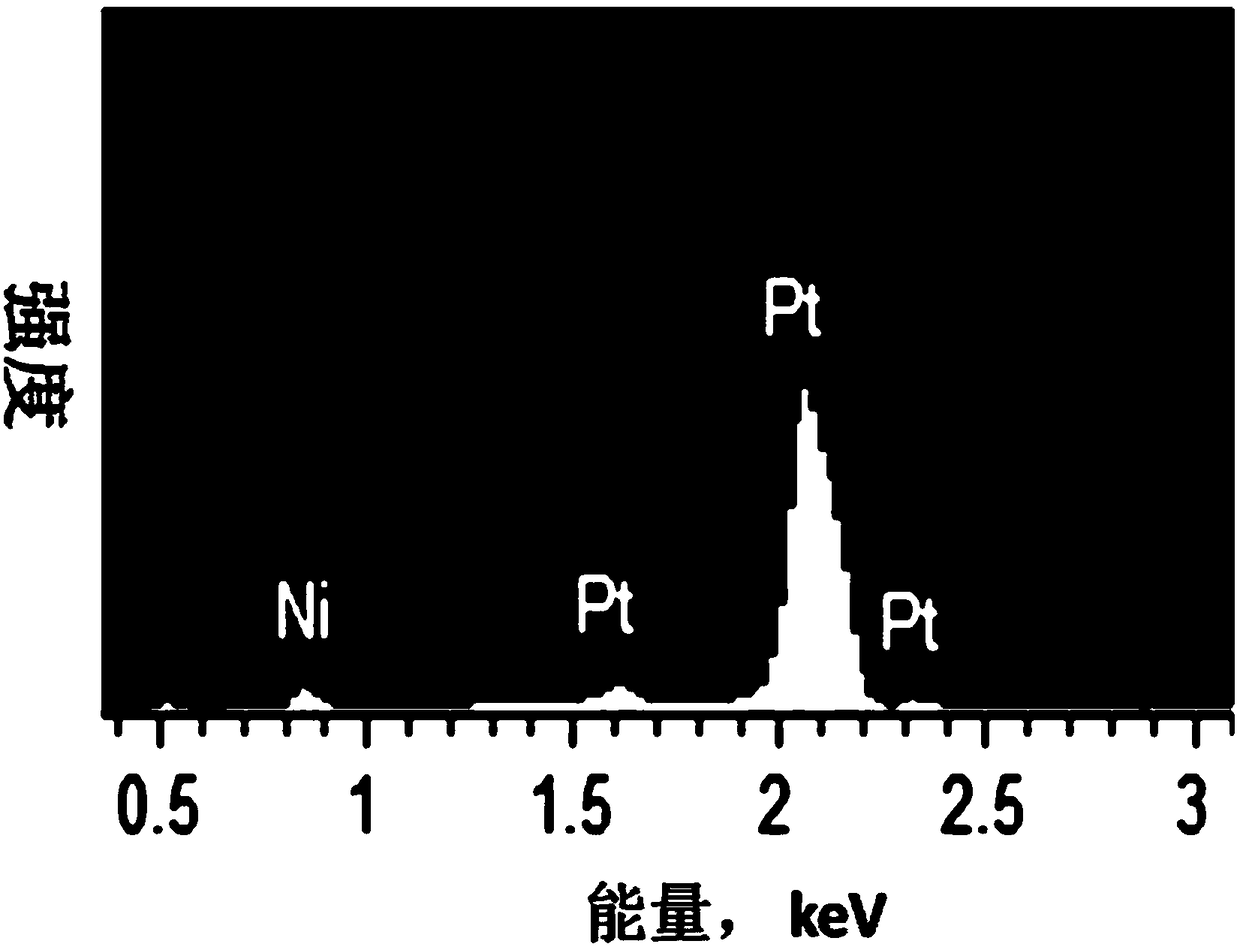

[0051] This embodiment provides an example of preparing a foam microporous nickel-platinum catalyst supported in situ, and the preparation method includes the following steps:

[0052] (1) The molecular formula of the selected formula is Zr 45 Ti 15 Ni 22 Pt 8 al 10 According to the formula, the raw materials are weighed, and the alloy melt is obtained after melting. The alloy melt is prepared by the crucible melt drawing method with a diameter of 120 μm and a length of about 50 m. The amorphous phase content is 95% Zr 45 Ti 15 Ni 22 Pt 8 al 10 alloy wire, and further weave the alloy wire into a mesh.

[0053] (2) at room temperature, clip 0.25 gram of Zr prepared in step (1) 45 Ti 15 Ni 22 Pt 8 al 10 Alloy wire mesh, which is submerged in 1L hydrofluoric acid aqueous solution with a concentration of 0.015mol / L for dealloying reaction. During the reaction, Zr, Ti, Al, and most of Ni at the reaction interface will react with hydrofluoric acid and become ions into ...

Embodiment 2

[0059] This embodiment provides an example of preparing a foam microporous gold-platinum alloy catalyst supported in situ, and the preparation method includes the following steps:

[0060] (1) The molecular formula of the selected formula is Zr 55 Ni 24 Au 7 Pt 7 Y 7 According to the formula, the raw materials are weighed, and the alloy melt is obtained after melting, and the alloy melt is prepared by the crucible-type melt drawing method to prepare the Zr 55 Ni 24 Au 7 Pt 7 Y 7 alloy wire, and further weave the alloy wire into a mesh.

[0061] (2) at room temperature, clip 0.3 gram of Zr prepared in step (1) 55 Ni 24 Au 7 Pt 7 Y 7 Alloy wire mesh, which is immersed in 2L of hydrofluoric acid aqueous solution with a concentration of 0.2mol / L for dealloying reaction. During the reaction, Zr, Y, and most of Ni at the reaction interface will react with hydrofluoric acid and become ions into the solution, while the remaining Au, Pt, and a small amount of Ni will form...

Embodiment 3

[0063] Present embodiment provides an example of the foam microporous gold-palladium alloy catalyst that prepares alloy wire (network) support, and this preparation method comprises the steps:

[0064] (1) The molecular formula of the selected formula is Zr 50 co 26 Au 7 PD 7 al 10 According to the formula, the raw materials are weighed, the alloy melt is obtained after melting, and the alloy melt is prepared by the crucible-type melt drawing method to prepare Zr with a diameter of 80 μm and a length of about 100 m. 50 co 26 Au 7 PD 7 al 10 alloy wire.

[0065] (2) at room temperature, clip 0.3 gram of Zr prepared in step (1) 50 co 26 Au 7 PD 7 al 10 Alloy wire, which is immersed in 1L of hydrofluoric acid aqueous solution with a concentration of 0.02mol / L for dealloying reaction. During the reaction, Zr, Al, and most of Co at the reaction interface will react with hydrofluoric acid and become ions into the solution, while the remaining Au, Pd, and a small amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com