Electrolytic copper crane sling

A crane, electrolytic copper technology, applied in the direction of load hanging components, transportation and packaging, can solve the problem of frequent and targeted changes in the shape and position of the pole plate lifting lugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

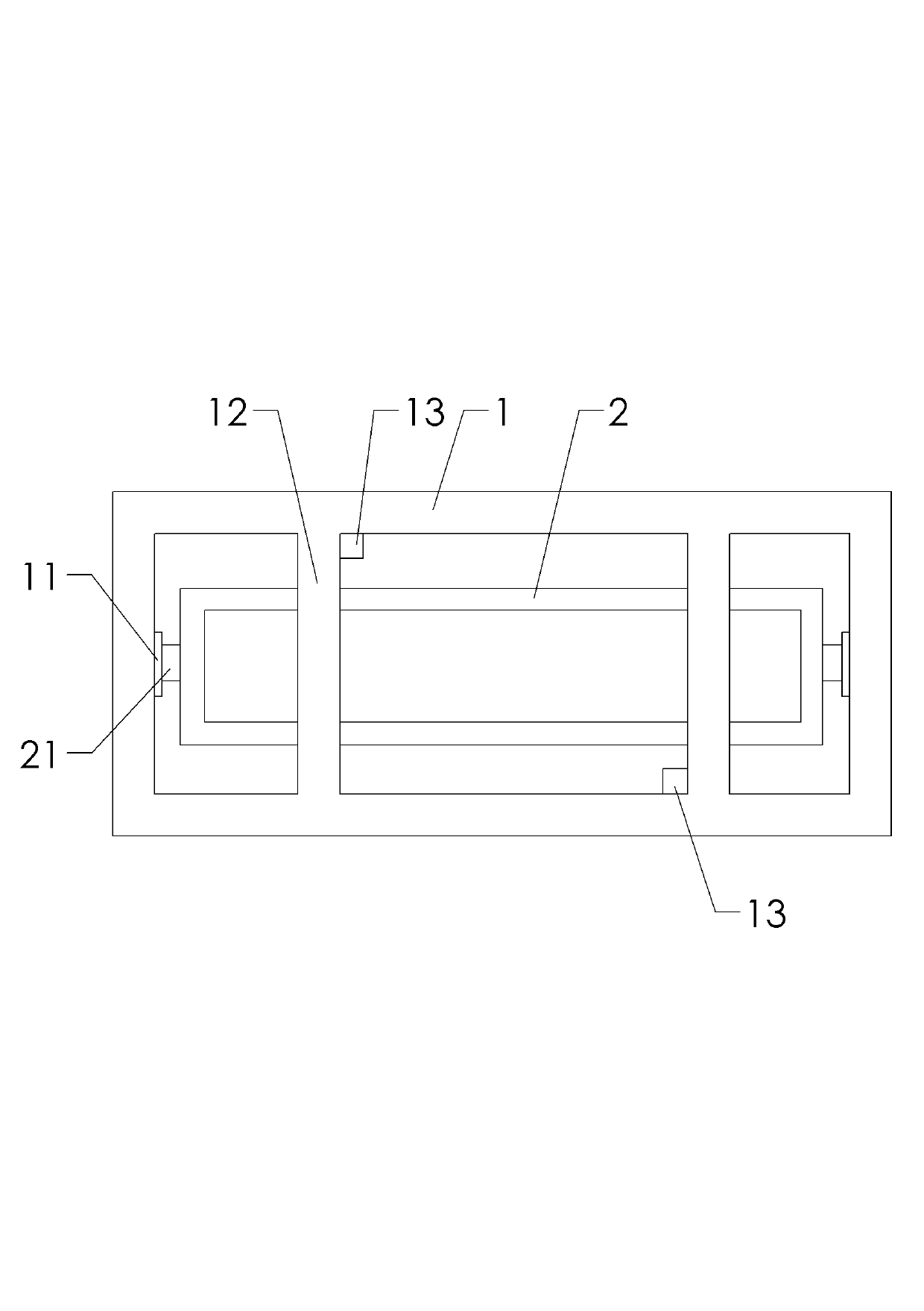

[0012] Such as figure 1 As shown: the electrolytic copper crane hanger in this implementation includes an anode hanger 1 and a cathode hanger 2, and two balance arms 12 are fixedly welded on the anode hanger 1, and the anode hanger 1 and the cathode hanger 2 are rectangular frame structures , the anode hanger 1 is located on the periphery of the cathode hanger 2, and the cathode hanger 2 is connected to the anode hanger 1 through the cathode hanger lifting device. The anode plate and the cathode plate are respectively arranged on the anode hanger and the cathode hanger according to the pole pitch. A camera 13 is also provided beside the two balance arms 12 .

[0013] In this embodiment, the cathode hanger hoisting device includes guide slides 11 fixed at both ends of the anode hanger 1 and guide wheels 21 fixed at both ends of the cathode hanger 2, the guide slides 11 and the guide wheels 21 are movably connected In order to realize the lifting movement of the cathode hanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com