REO (rare earth oxide) down-conversion material perovskite solar cell and preparation method

A technology of rare earth oxides and conversion materials, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unstable photoelectric performance and poor performance of perovskite solar cells, and achieve enhanced photoelectric conversion efficiency and photostability. The effect of reducing difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

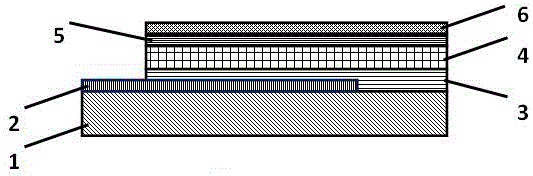

preparation example Construction

[0039] The preparation method of the present invention comprises the following specific steps:

[0040] ① Cleaning of the glass substrate.

[0041] Clean the ordinary glass or quartz glass substrate, use acetone and absolute ethanol mixed solvent (volume ratio 1:3) and deionized water to ultrasonically clean the substrate, for example, clean for 15 minutes, and dry the substrate with nitrogen .

[0042] ② Chemically etch the FTO transparent conductive glass substrate to obtain corresponding structural graphics; clean to obtain a transparent conductive substrate.

[0043]③ Preparing a metal oxide dense layer in the region of the target pattern by chemical bath deposition.

[0044] ④Using sol method and hydrothermal synthesis method to prepare rare earth oxide down-conversion nanomaterials, including cerium oxide doped with europium or gadolinium, gadolinium aluminate, gadolinium oxide, and yttrium oxide powder.

[0045] ⑤ Stirring the prepared rare earth oxide down-conversio...

Embodiment 1

[0051] Example 1 Preparation of Europium-doped Cerium Oxide Down Conversion Material Porous Structure Organic-Inorganic Perovskite Solar Cell

[0052] (a) Cleaning the FTO glass substrate 1: ultrasonic cleaning with acetone, alcohol, and deionized water for 15 minutes respectively, and then drying with pure nitrogen;

[0053] (b) Etching the transparent conductive film 2 with 0.1M dilute hydrochloric acid and zinc powder, and then cleaning and drying in the same way as the glass substrate cleaning method;

[0054] (c) Immerse the etched conductive glass into the prepared 0.2M TiCl 4 solution, airtightly placed in a drying oven at 70 °C for 1 h, washed the sample with deionized water and ethanol, and annealed at 100 °C for 1 h;

[0055] (d) The cerium oxide doped with europium is mixed with cerium nitrate, europium nitrate and sodium phosphate to form an aqueous solution, then added to a hydrothermal reactor, reacted at 180 degrees Celsius for 12 hours, centrifuged, washed wit...

Embodiment 2

[0061] Example 2 Preparation of organic-inorganic perovskite solar cells with porous structure of europium-doped gadolinium vanamate down-conversion material

[0062] When gadolinium vanitate doped with europium is used as the down conversion material, the preparation process is the same as in Example 1 except for the rare earth material preparation step. The preparation process of gadolinium vanamate doped with europium is as follows: mix gadolinium nitrate, europium nitrate, ammonium vanamate and ammonia water, the molar ratio of nitrate and ammonium vanamate is 1 to 2, adjust the pH to 7 by increasing the amount of ammonia water, stir After 1 hour, pour it into a reaction kettle at 185°C and react for 24 hours. The centrifugate was washed three times with distilled water and dried overnight at 120°C. The prepared planar organic-inorganic perovskite solar cells with a porous structure have the same structure as figure 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com