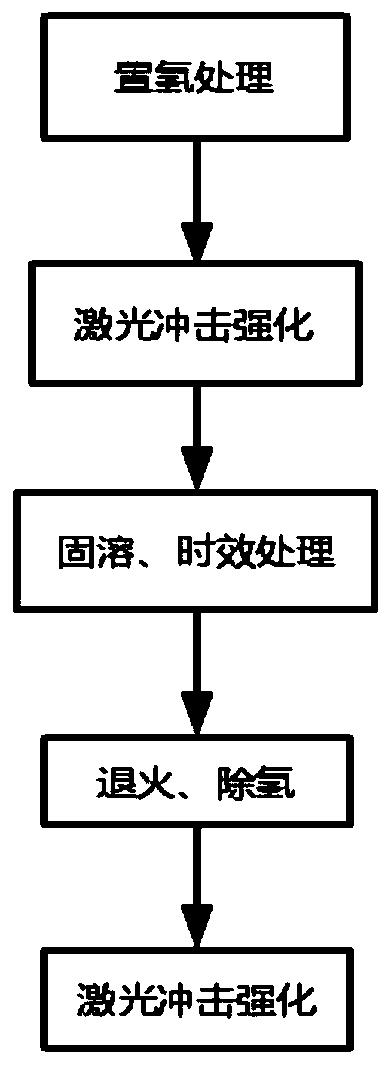

Method for laser shock assisted thermo-hydrogenation treatment of Ti6Al4V alloy

A technology of laser shock and hydrogen treatment, which is applied in the field of laser shock-assisted thermal hydrogen treatment of Ti6Al4V alloys, can solve the problems of uneven distribution of hydrogen elements, high hydrogen pressure, cracks, etc. The effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Thermal Hydrogen Treatment Improves Properties of Titanium Alloys

[0024] Grind the Ti6Al4V sample, after ultrasonic cleaning, put it into the electronic balance for weighing, then put it into the tubular hydrogen treatment furnace, vacuumize the furnace and start the heating treatment furnace, raise the temperature to 750 ° C, and then pass into the furnace The volume fraction of 99.9% high-purity hydrogen gas increases the hydrogen pressure in the treatment furnace to 20kPa, and the holding time is 1h. After putting the hydrogen in, take out the titanium alloy sample, put it into the electronic balance again and weigh it, and calculate and confirm that the content of hydrogen element is 0.2wt%. Put the titanium alloy sample after hydrogenation into the heat treatment furnace, first raise the temperature of the furnace to 450°C, keep it for 10 minutes, then raise the temperature of the furnace to 850°C, keep it for 7 hours, stop the heat preservation and let it cool d...

example 2

[0026] Improvement of Properties of Titanium Alloy by Laser Shock-Hydrogen Combination

[0027] Grind the Ti6Al4V sample, after ultrasonic cleaning, put it into the electronic balance for weighing, then put it into the tubular hydrogen treatment furnace, vacuumize the furnace and start the heating treatment furnace, raise the temperature to 750 ° C, and then pass into the furnace The volume fraction of 99.9% high-purity hydrogen gas increases the hydrogen pressure in the treatment furnace to 20kPa, and the holding time is 1h. After putting the hydrogen in, take out the titanium alloy sample, put it into the electronic balance again and weigh it, and confirm that the content of hydrogen element is 0.2wt%. Then place the hydrogen-treated titanium alloy in a heat treatment furnace and perform the first laser shock. The parameters of the laser shock are pulse energy 2J, spot diameter 3mm, laser wavelength 1024nm, frequency 10Hz, and pulse width 20ns. , the spot overlapping rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com