Injection moulding method for Ti6A14V alloy gel

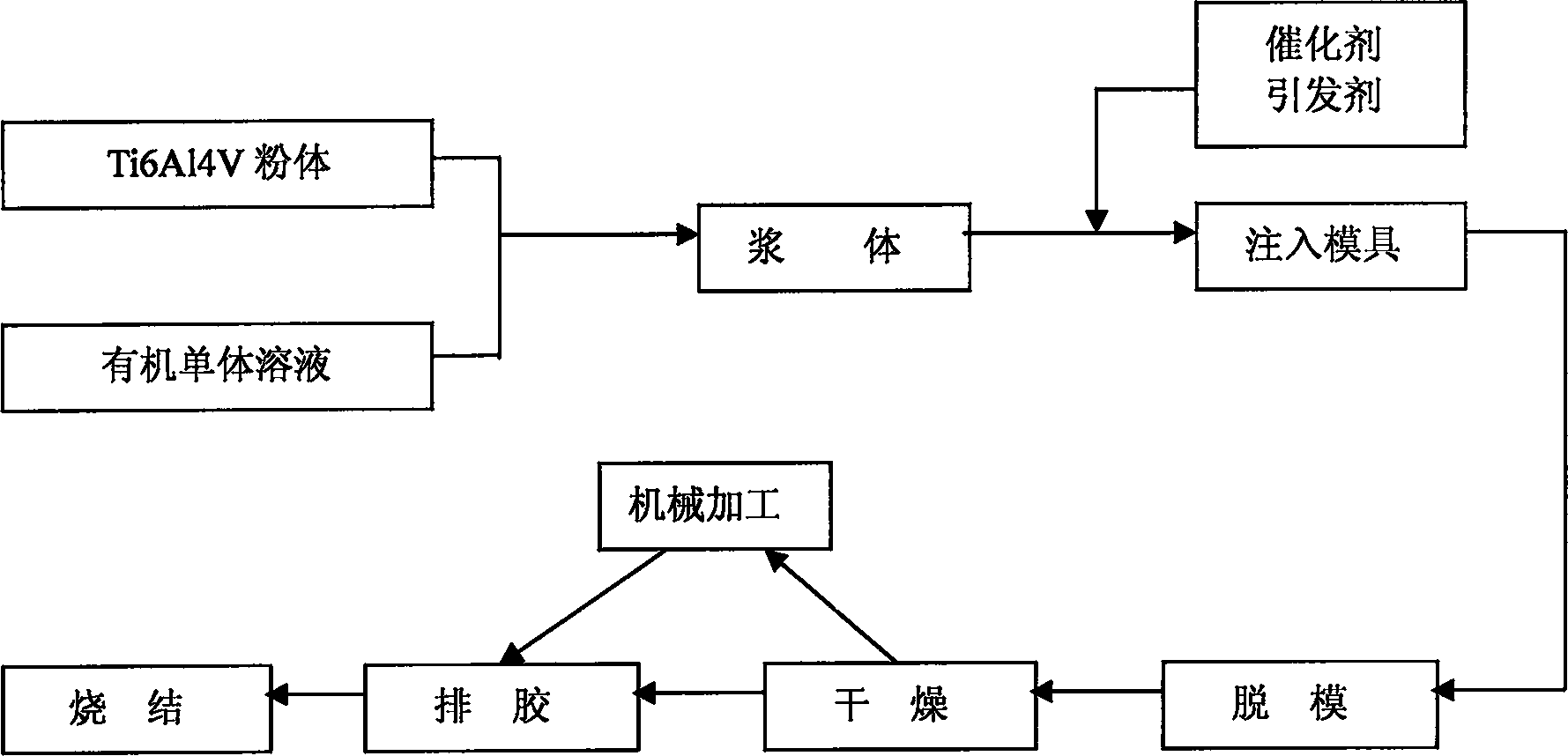

A gel injection molding, ti6al4v technology, applied in the field of titanium alloy forming, can solve the problems of component segregation structure, defects and even collapse, unsuitable for large-scale forming, etc., and achieve the effect of low organic content, less body shrinkage, and less organic content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The powder is prepared from hydrogenated-dehydrogenated Ti6Al4V powder and gas atomized Ti6Al4V powder, wherein the mass percentage of gas atomized Ti6Al4V powder is 90%. The concentration of acrylamide in the premix is 15%, and the mass ratio of acrylamide:methylenebisacrylamide is 90:1. Add 475 grams of the prepared powder and 1 gram of isooctanol as a defoaming agent to every 100 mL of the premix. After stirring evenly, add catalyst tetramethyl ethylenediammonium (25 μL per 100 mL of slurry), initiator ammonium persulfate (10% by mass, add 15 μL per 100 mL of slurry), stir for 10s, and quickly pour into the mold , drying in an oven at 60°C for 0.5 hours, demoulding, drying in an oven at 60°C for 6 hours, and taking out. in vacuum degree 10 -4 Pa, degreasing at 350°C for 30 minutes, sintering at 1250°C for 3 hours, and cooling with the furnace to obtain titanium alloy parts with better comprehensive mechanical properties and higher dimensional accuracy.

Embodiment 2

[0028] The concentration of hydroxyethyl methacrylate in the premix solution is 20%, and the mass ratio of hydroxyethyl methacrylate:methylenebisacrylamide is 30:1. Add 550 grams of aerosolized Ti6Al4V powder and 2 grams of defoamer fatty acid to each 100mL of the premix. After stirring evenly, add catalyst tetramethylethylenediammonium (30μL per 100mL slurry), initiator potassium persulfate (8% by mass, add 50μL per 100mL slurry), stir for 5s, and quickly pour into the mold , vacuum drying in a 50°C oven for 1 hour, demolding, and drying in an oven at 50°C for 15 hours to take out. in vacuum degree 10 -3 Pa, degreased at 400℃ for 20 minutes, sintered at 1300℃ for 2 hours, and cooled with the furnace to obtain titanium alloy parts with better comprehensive mechanical properties and higher dimensional accuracy.

Embodiment 3

[0030] The powder is prepared from hydrogenated-dehydrogenated Ti6Al4V powder and gas atomized Ti6Al4V powder, wherein the mass percentage of gas atomized Ti6Al4V powder is 80%. The concentration of hydroxypropyl methacrylate in the premix solution is 20%, and the mass ratio of hydroxypropyl methacrylate:methylenebisacrylamide is 100:1. Add 500 grams of prepared powder and 2 grams of defoamer tributyl phosphate to each 100 mL of premix. After stirring evenly, add catalyst tetramethyl ethylenediammonium (30 μL per 100 mL of slurry), initiator ammonium persulfate (10% by mass, add 50 μL per 100 mL of slurry), stir for 5s, and quickly pour into the mold , dried in an oven at 70°C for 0.5 hours, demolded, put in an oven and dried at 70°C for 20 hours and taken out. in vacuum degree 10 -3 Pa, degreasing at 350°C for 30 minutes, sintering at 1300°C for 2 hours, and cooling with the furnace to obtain titanium alloy parts with better comprehensive mechanical properties and higher di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com