Beta annealing heat treatment method for Ti6Al4V alloy forge piece

An annealing heat treatment, ti6al4v technology, applied in the field of heat treatment of metal materials, can solve the problems of low fatigue crack growth rate, microstructure and properties that cannot meet the requirements of specifications, and achieve low fatigue crack growth rate, high strength, simple and stable process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

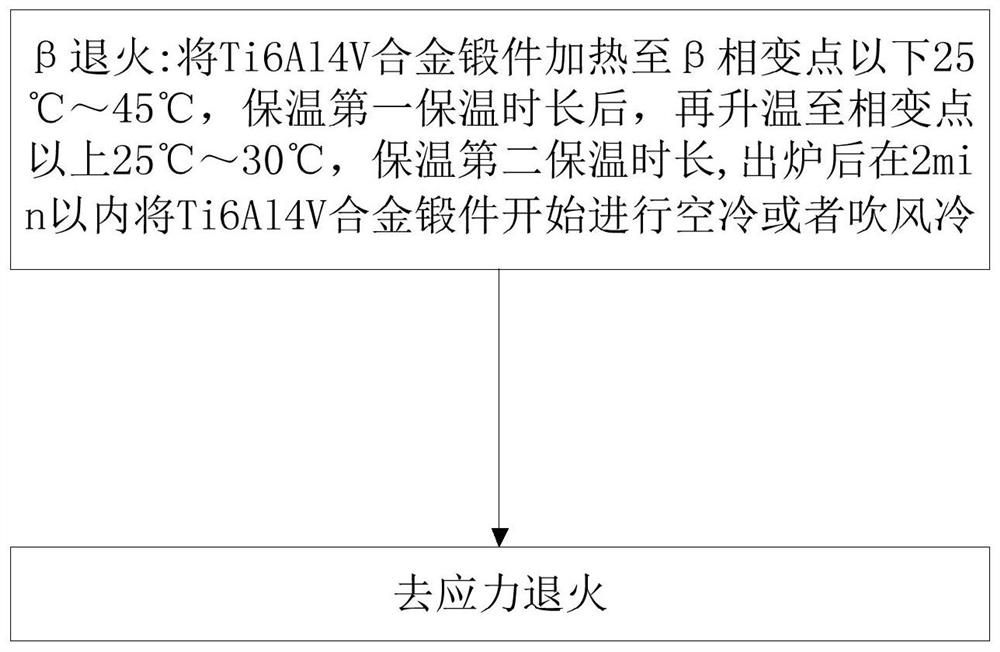

[0030] figure 1 A schematic flow sheet of the Ti6Al4V alloy forging β annealing heat treatment method provided by an example of the present invention, as figure 1 As shown, the β annealing heat treatment method for Ti6Al4V alloy forgings includes:

[0031] The first step: beta annealing

[0032] Heat the wrought Ti6Al4V alloy to 25°C-45°C below the β-transition point, keep it warm for 60-120 minutes, then take 35-45 minutes to raise the temperature to 25-30°C above the transformation point, hold it for 40-60 minutes, and leave the furnace Finally, transfer and disperse the forging within 2 minutes, and carry out air cooling or blowing cooling.

[0033] The second step: stress relief annealing.

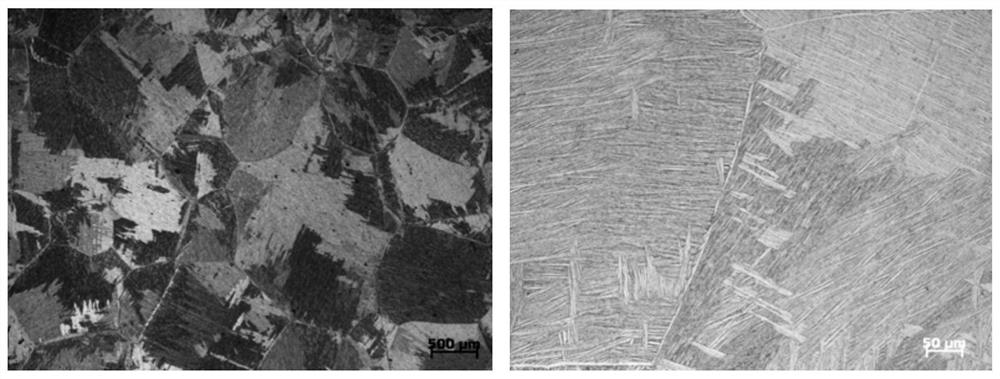

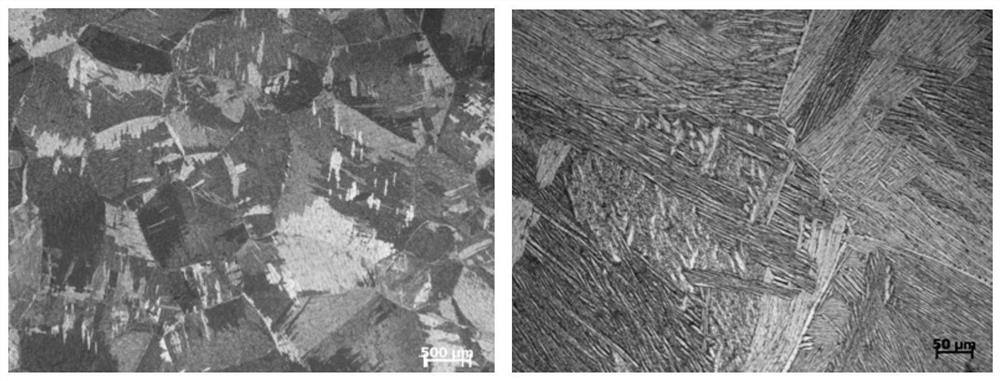

[0034] figure 2 A schematic diagram of the microstructure of a heat-treated Ti6Al4V alloy forging provided for an example of the present invention. In this example, a Ti6Al4V alloy forging with an external dimension of 768.3×575×172.5 is used, and its effective thickness is 45mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com