Composite modifier capable of improving overall performance of zinc-aluminum alloy

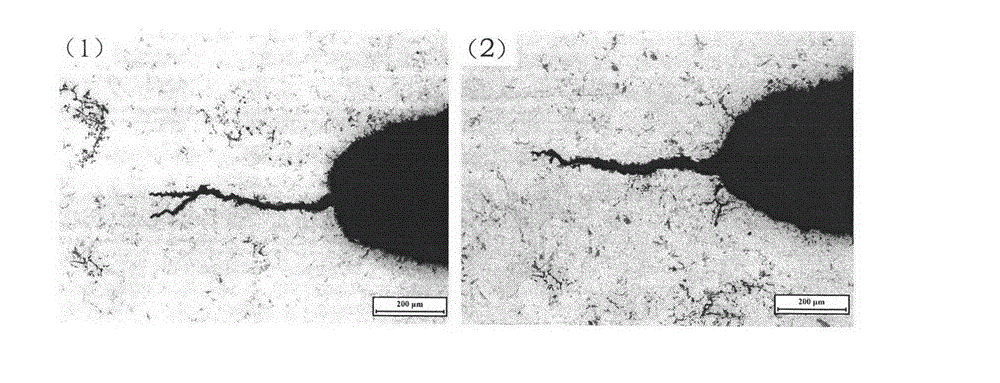

A technology of composite modifier and zinc-aluminum alloy, which is applied in the field of composite modifier, can solve problems such as the large solidification temperature range of zinc-aluminum alloy, poor thermal strength of zinc-aluminum alloy, and no strengthening effect, so as to reduce the crack growth rate, Effects of improving performance and delaying the time of crack generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

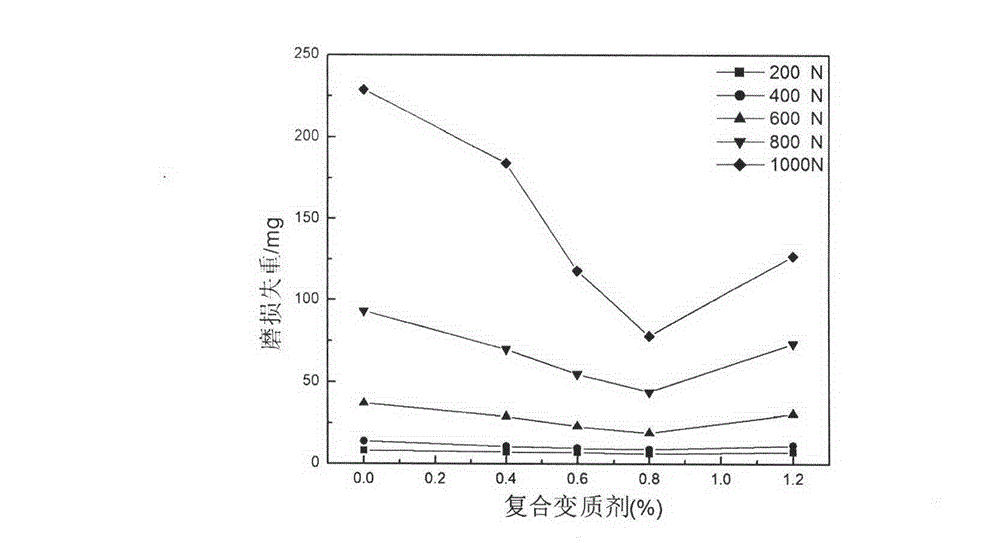

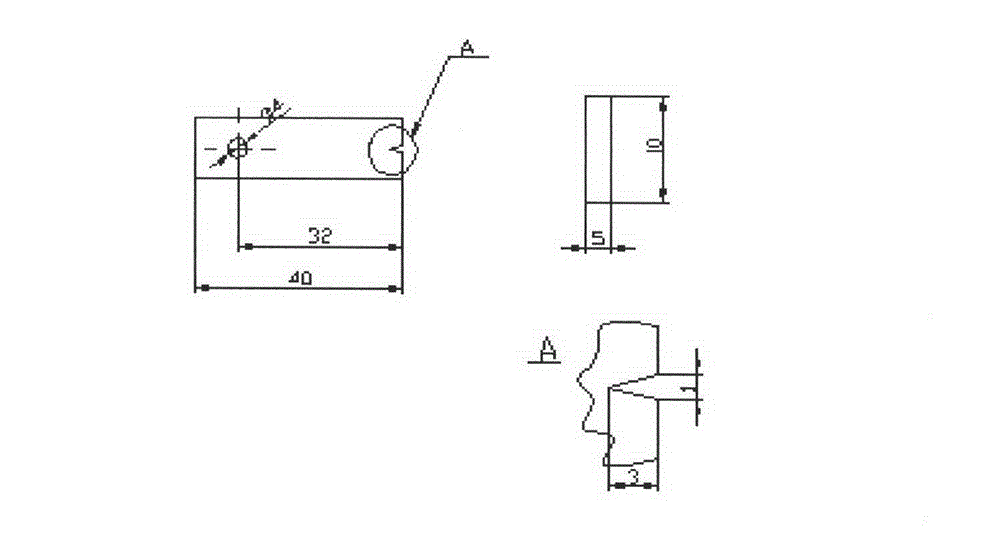

Embodiment 1

[0012] Industrial aluminum ingot No. A00, zinc ingot No. 0, electrolytic copper, composite modifier (including Ni20-30%, Ti15-25%, Mn5-15%, Cr5-15%, Si5-10%, Ce5-10%, La5-10%, Y1-6%, Nb1-6%, V1-6%, the rest is aluminum), pure magnesium as raw materials. The composition is calculated by weight percentage, and weighed according to the proportion of Al28%, Cu2.3% (added in the form of aluminum-copper master alloy containing 50% copper), composite modifier 0-1.2%, Mg0.015%, and the balance is Zn It is then melted in an induction melting furnace. The smelting process is as follows: first add aluminum ingots, zinc ingots, aluminum-copper intermediate alloys, and composite modifiers. After the materials are completely melted, heat them up to 600-650°C and keep them warm for 6min-8min to homogenize each element, in order to reduce the burning loss of magnesium. Use a bell jar to press magnesium into molten metal, and use 0.2% dehydrated ZnCl containing molten metal 2 For refining, u...

Embodiment 2

[0017] Industrial aluminum ingot No. A00, zinc ingot No. 0, electrolytic copper, composite modifier (Ni20-30%, Ti15-25%, Mn5-15%, Cr5-15%, Si5-10%, Ce5-10%, La5 -10%, Y1-6%, Nb1-6%, V1-6%, the rest is aluminum), pure magnesium as raw materials. The composition is calculated by weight percentage, and weighed according to the proportion of Al28%, Cu2.3% (added in the form of aluminum-copper master alloy containing 50% copper), composite modifier 0-1.2%, Mg0.015%, and the balance is Zn It is then melted in an induction melting furnace. The smelting process is as follows: first add aluminum ingots, zinc ingots, aluminum-copper intermediate alloys, and composite modifiers. After the materials are completely melted, heat them up to 600-650°C and keep them warm for 6min-8min to homogenize each element, in order to reduce the burning loss of magnesium. Use a bell jar to press magnesium into molten metal, and use 0.2% dehydrated ZnCl containing molten metal 2 For refining, use a bell...

Embodiment 3

[0020] Industrial aluminum ingot No. A00, zinc ingot No. 0, electrolytic copper, composite modifier (Ni20-30%, Ti15-25%, Mn5-15%, Cr5-15%, Si5-10%, Ce5-10%, La5 -10%, Y1-6%, Nb1-6%, V1-6%, the rest is aluminum), pure magnesium as raw materials. The composition is calculated by weight percentage, and weighed according to the proportion of Al28%, Cu2.3% (added in the form of aluminum-copper master alloy containing 50% copper), composite modifier 0-1.2%, Mg0.015%, and the balance is Zn It is then melted in an induction melting furnace. The smelting process is as follows: first add aluminum ingots, zinc ingots, aluminum-copper intermediate alloys, and composite modifiers. After the materials are completely melted, heat them up to 600-650°C and keep them warm for 6min-8min to homogenize each element, in order to reduce the burning loss of magnesium. Use a bell jar to press magnesium into molten metal, and use 0.2% dehydrated ZnCl containing molten metal 2 For refining, use a bell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com