Device and method for pyrolyzing pea coal by utilizing internally heated vertical furnace

An internal heating type, vertical furnace technology, applied in the field of coal chemical industry, can solve the problems of low calorific value and high nitrogen content, and achieve the effect of good semi-coke quality, simple operation and reduced nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

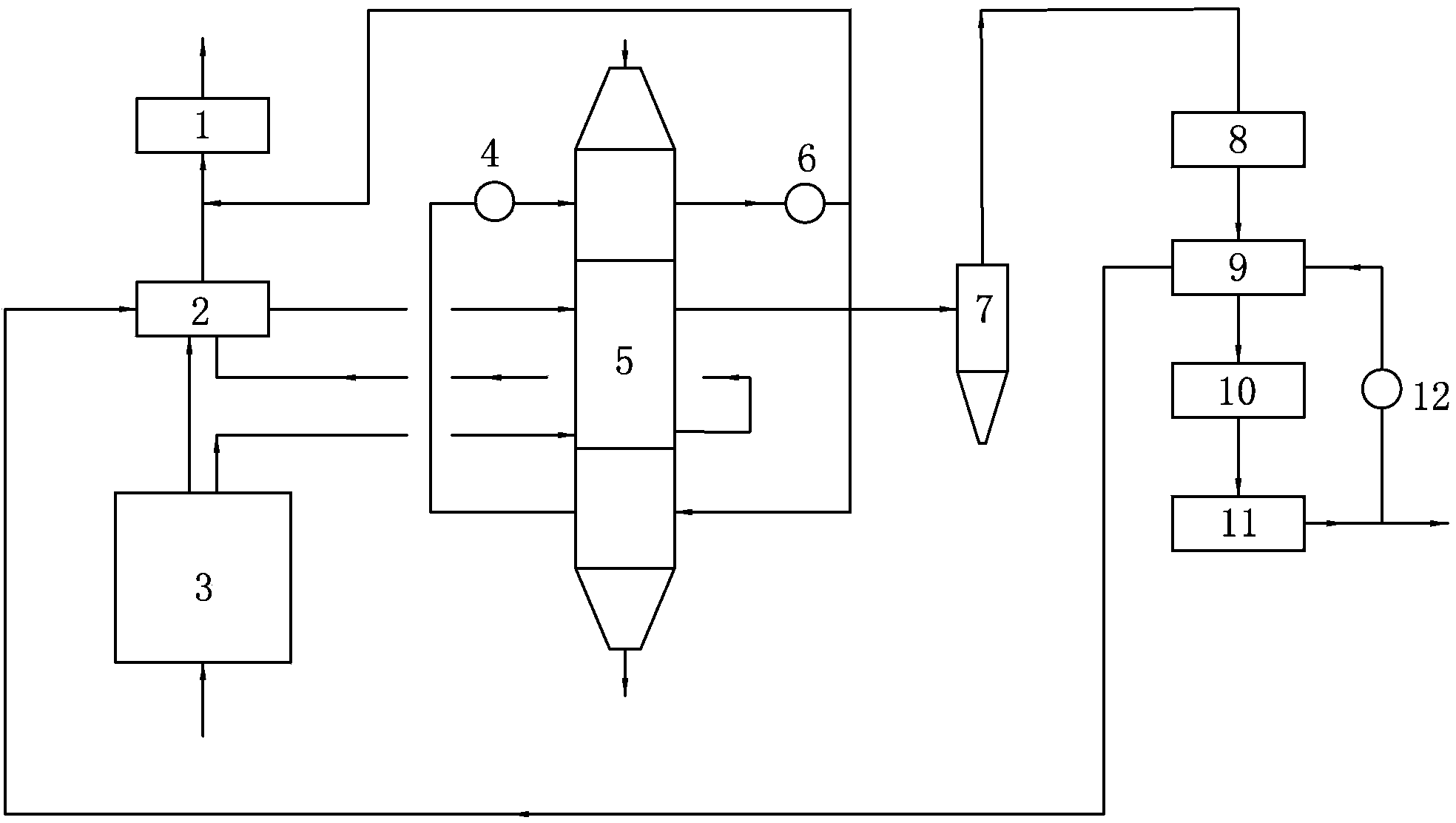

[0031] Depend on Figure 1~3 It can be seen that the device for pyrolyzing granulated coal using an internal heating type vertical furnace in this embodiment is composed of a bag filter 1, a gas heat exchanger 2, a combustion furnace 3, a high-temperature steam circulation fan 4, an internal heating type vertical furnace 5, and a drying steam circulation fan 6. A micro-cyclone dust collector 7, a quench cooler 8, a raw gas heat exchanger 9, a horizontal tube cooler 10, an electric tar replenisher 11 and a gas circulation fan 12 are connected to form.

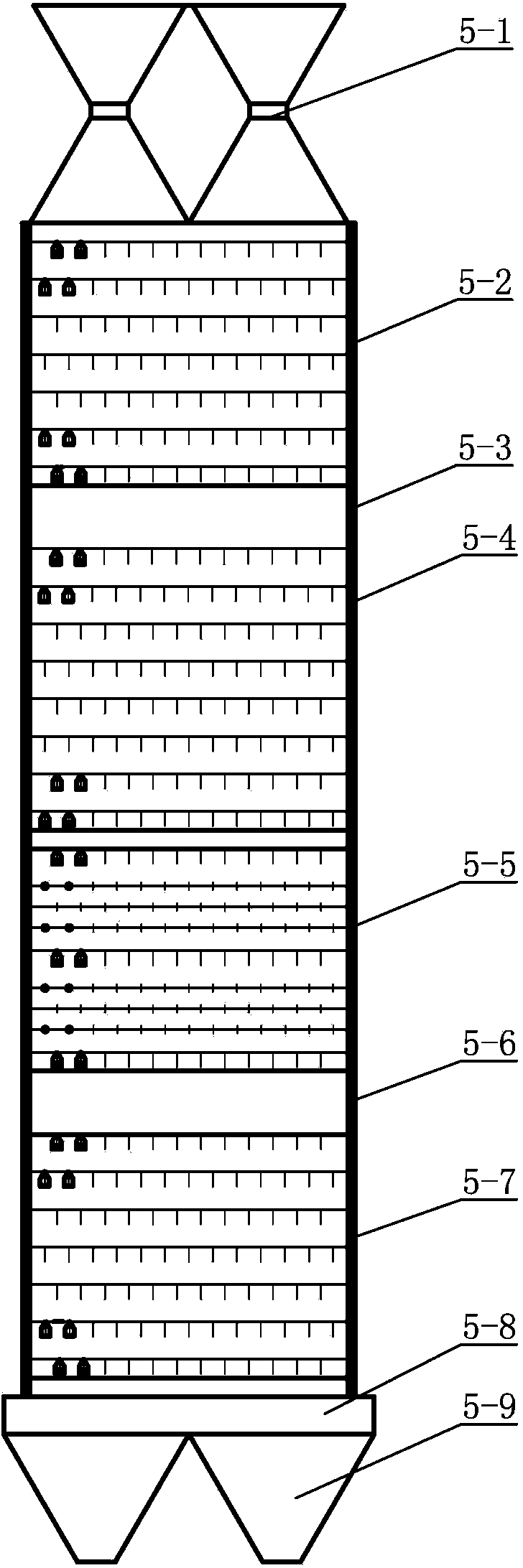

[0032] The internal heating type vertical furnace 5 of the present embodiment adopts a square furnace, and the furnace wall is formed by pouring a heat-insulating refractory material and a wear-resistant refractory material, see figure 2 , the internal heating type vertical furnace 5 is divided into a feed hopper 5-1, a drying section 5-2, a first transition section 5-3, a pyrolysis section 5-4, a pyrolysis section 5-5, and a p...

Embodiment 2

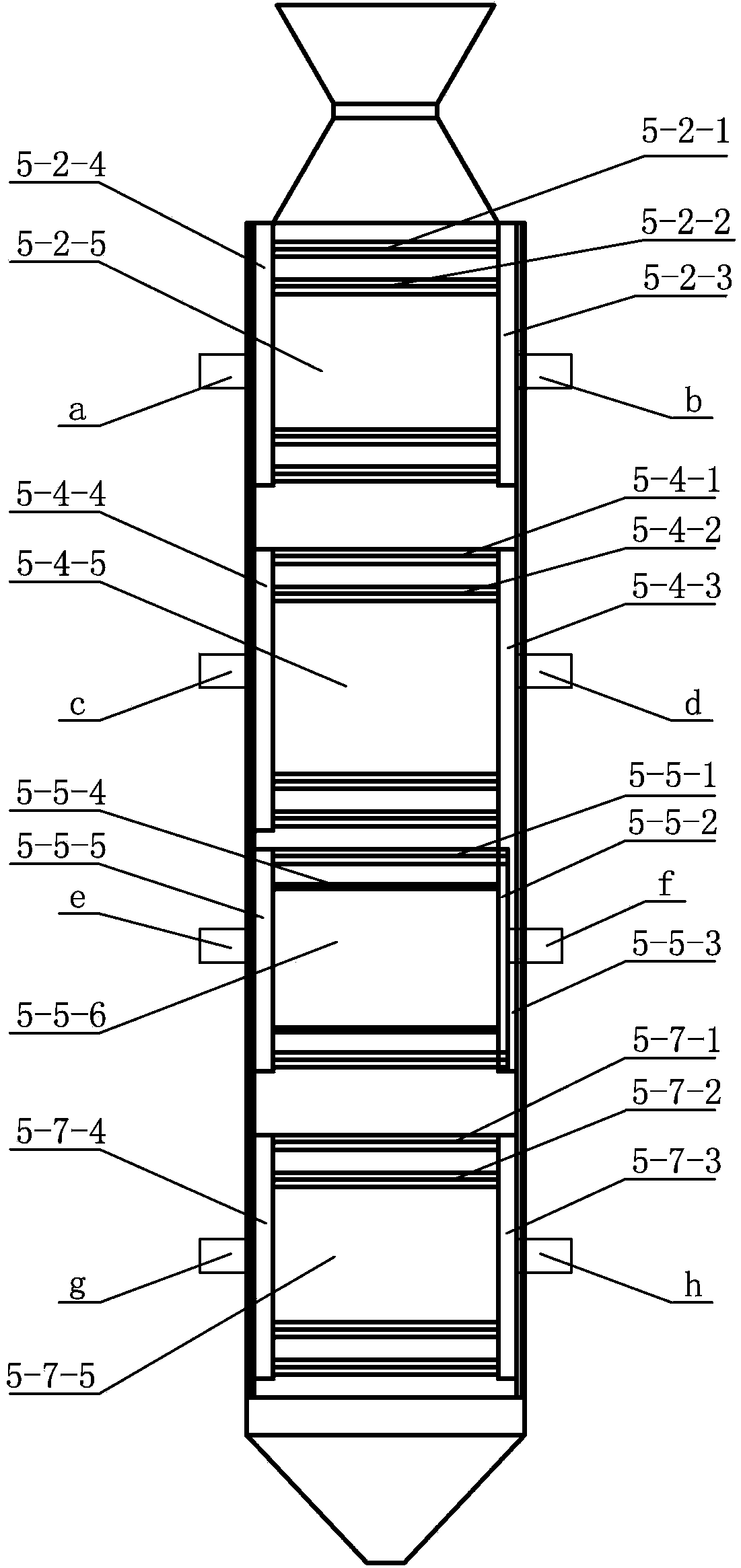

[0057] The drying section 5-2 of the present embodiment is provided with a dry steam inlet chamber 5-2-4 and a dry steam outlet chamber 5-2-3 respectively on the left and right sides of the drying chamber 5-2-5. Room 5-2-5 is equipped with 4 rows of dry steam export tanks 5-2-1 and 3 rows of dry steam import tanks 5-2-2, dry steam export tanks 5-2-1 and dry steam import tanks 5-2 -2 Arranged staggered up and down, in the horizontal direction, each row is arranged with 15 dry steam outlet grooves 5-2-1 or dry steam inlet grooves 5-2-2, the groove spacing is 400mm, in the vertical direction, The distance between a row of dry steam outlet grooves 5-2-1 and an adjacent row of dry steam inlet grooves 5-2-2 is 1200 mm. The dry steam outlet grooves 5-2-1 and the dry steam inlet grooves 5-2 of this embodiment The longitudinal section of 2-2 is an inverted V-shaped groove extending longitudinally on both sides. The apex angle of the inverted V-shaped groove is 55°C, the length of the s...

Embodiment 3

[0066]The drying section 5-2 of the present embodiment is provided with a dry steam inlet chamber 5-2-4 and a dry steam outlet chamber 5-2-3 respectively on the left and right sides of the drying chamber 5-2-5. Chamber 5-2-5 is equipped with 7 rows of dry steam export tanks 5-2-1 and 6 rows of dry steam import tanks 5-2-2, dry steam export tanks 5-2-1 and dry steam import tanks 5-2 -2 Arranged staggered up and down, in the horizontal direction, each row is arranged with 10 dry steam outlet grooves 5-2-1 or dry steam inlet grooves 5-2-2, the groove spacing is 800mm, in the vertical direction, The distance between a row of dry steam outlet grooves 5-2-1 and an adjacent row of dry steam inlet grooves 5-2-2 is 800 mm. The dry steam outlet grooves 5-2-1 and the dry steam inlet grooves 5-2 of this embodiment The longitudinal section of 2-2 is an inverted V-shaped groove extending longitudinally on both sides. The apex angle of the inverted V-shaped groove is 65°C, the length of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com