Forward-reverse combined construction method for foundation pit of non-permanent vertical support system

A technology of vertical support and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems that the verticality of steel columns cannot meet the requirements of high precision, the construction site of the basement roof cannot be used, and the environmental impact of the reverse method cannot be achieved. Achieve the effect of saving engineering cost, large support stiffness and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

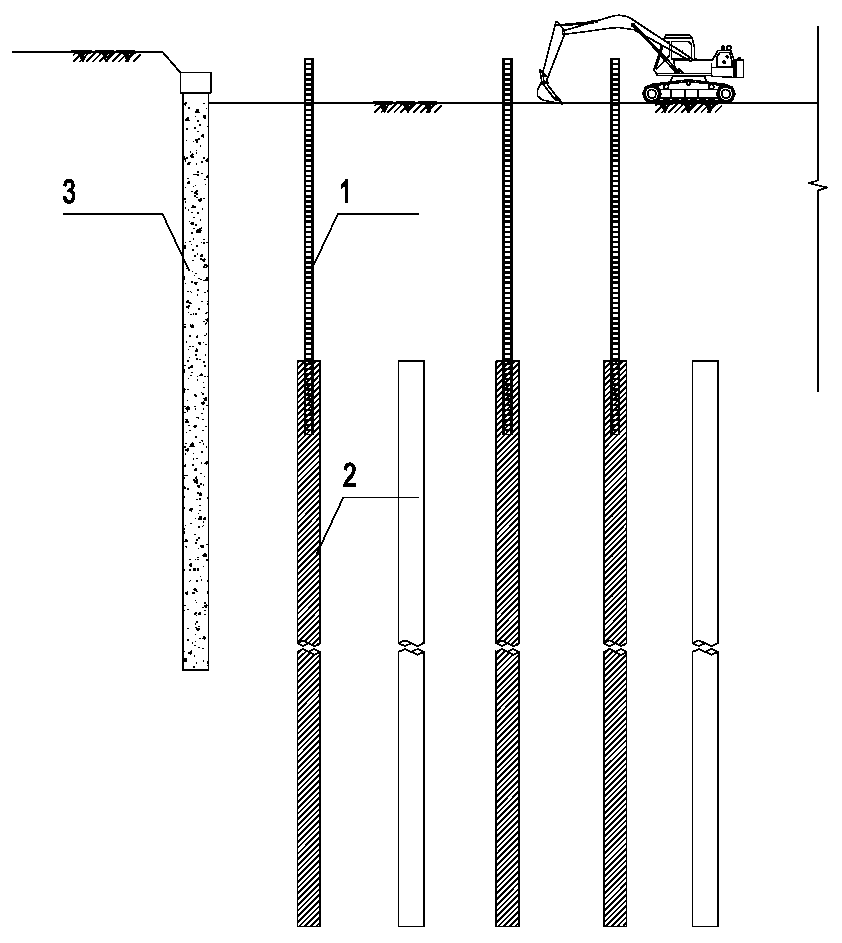

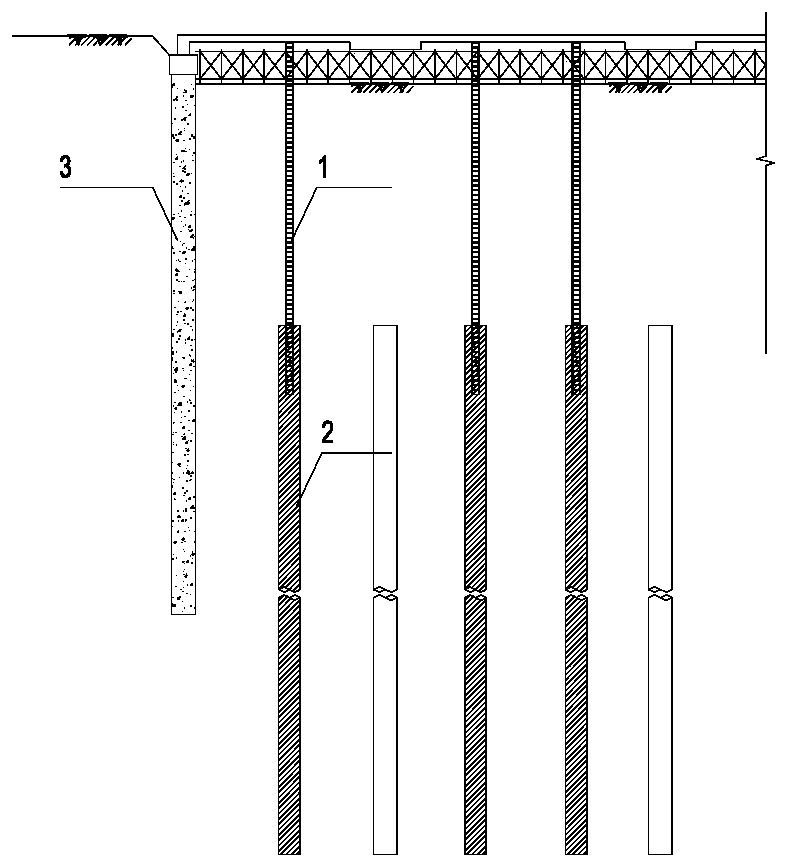

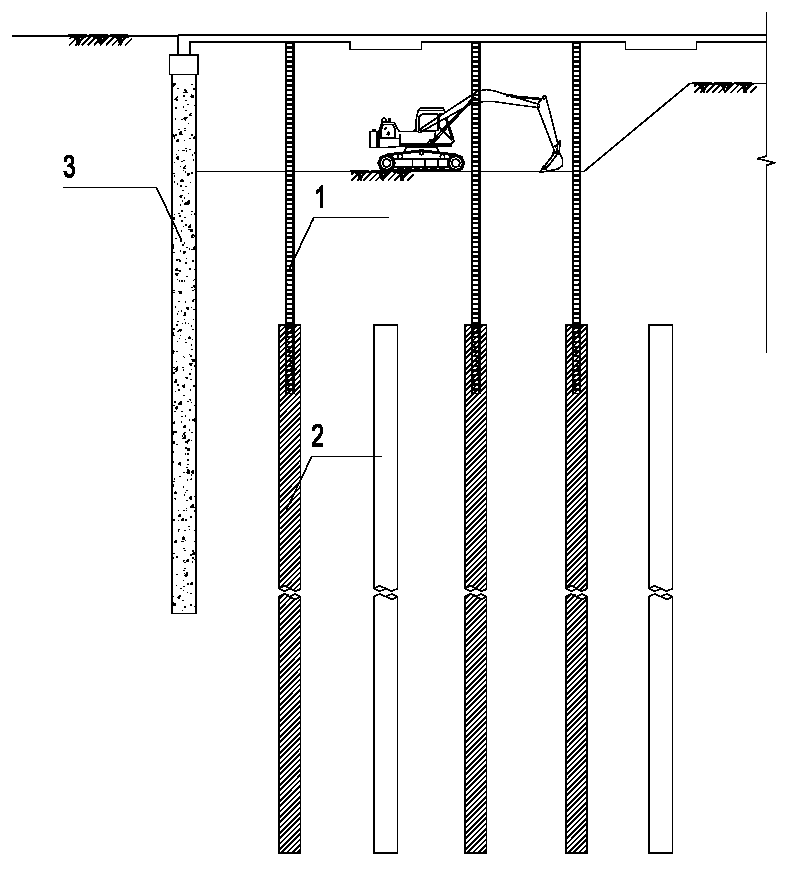

[0041] Combine below Figure 1 to Figure 15 Taking the underground three-story foundation pit as an example, the construction method of the foundation pit of the non-permanent vertical support system of the present invention is described in detail.

[0042] A foundation pit construction method combining forward and backward for a non-permanent vertical support system, comprising the following steps:

[0043] Step 1: Complete the construction of temporary steel columns 1, column piles 2, and enclosure structure 3 of the foundation pit, excavate the first layer of earthwork to a certain distance below the elevation of the basement roof, and pour concrete cushions as they are excavated;

[0044] Step 2: Build construction bents, and pour construction basement roof structure 4;

[0045] Step 3: Continue to excavate the second layer of earthwork to a certain distance below the floor level of the basement floor, and pour the concrete cushion as it is excavated;

[0046] Step 4: Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com