Pyrolysis method for low-rank coal or oil shale with higher tar yield

A low-rank coal and oil shale technology, applied in the field of low-rank coal or oil shale pyrolysis upgrading, can solve the problems of low tar yield and high dust content in tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

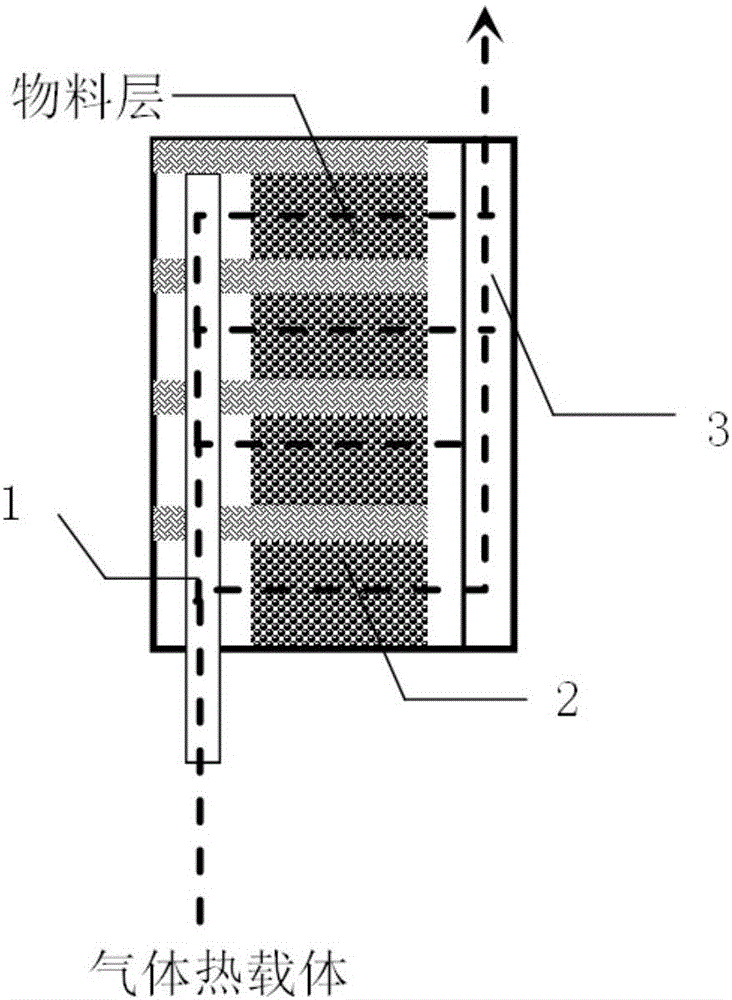

[0013] Example 1 shows the opinion figure 1 . The material is long flame coal. Combustion chamber 1 (hot end), carbonization chamber 2 and gas collection chamber 3 (cold end) combined units are arranged separately. In this moving bed reactor, the distance between the cold and hot ends is 50cm, the coal material moves from top to bottom, and the gas heat carrier penetrates the coal material in the carbonization chamber 2 radially from the combustion chamber 1 (hot end) and enters the gas collection In chamber 3 (cold end), the heat carrier gas and coal material undergo rapid gas-solid heat exchange, and the temperature of the gas heat carrier is rapidly cooled from 800°C to 120°C. The coal material is heated to undergo low-temperature pyrolysis, and the heating rate of the coal material is between 50°C / min and 600°C / min. The temperature gradient between the cold end and the hot end is 800°C / m. The oil-gas mixture produced by pyrolysis is led out from the gas collection cham...

Embodiment 2

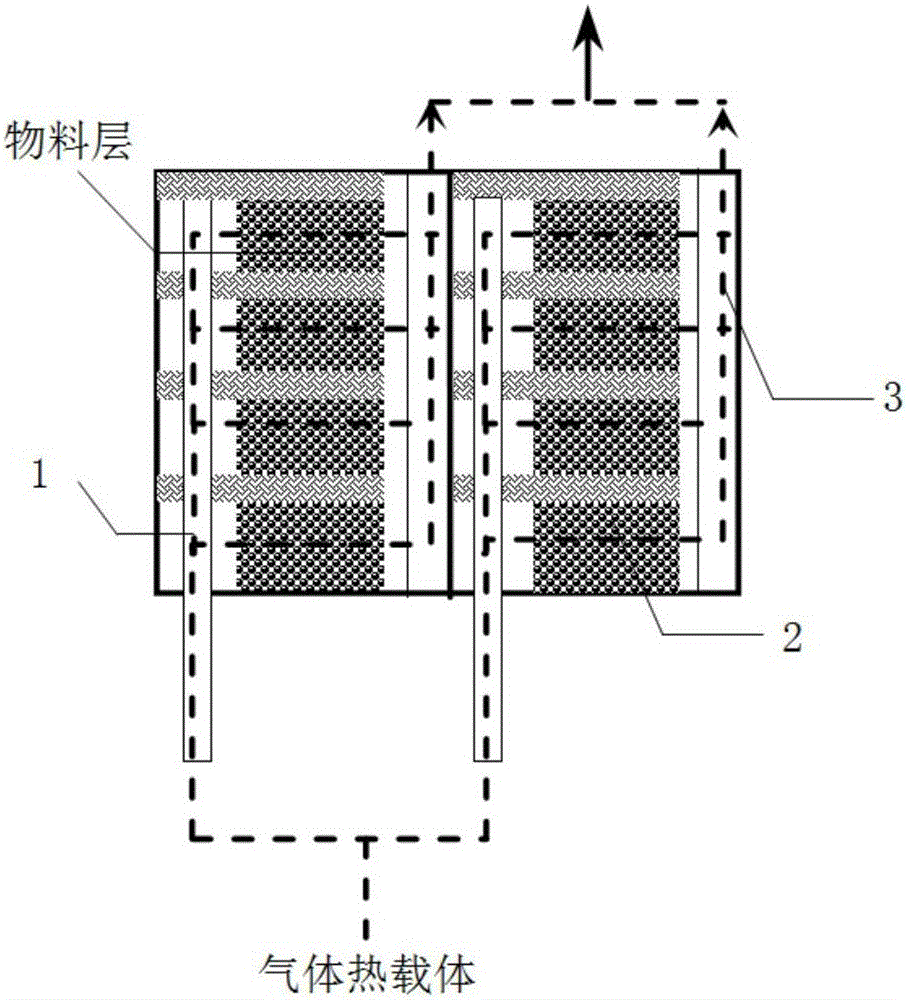

[0015] Example 2 shows the opinion figure 2 . The material is lignite. Combustion chamber 1 (hot end), carbonization chamber 2 and gas collection chamber 3 (cold end) combined units are arranged on the same side. In this moving bed reactor, the distance between the cold and hot ends is 60cm, the coal material moves from top to bottom, and the gas heat carrier penetrates the coal material in the carbonization chamber 2 radially from the combustion chamber 1 (hot end) and enters the gas collection In chamber 3 (cold end), the heat carrier gas and coal material undergo rapid gas-solid heat exchange, and the temperature of the gas heat carrier is rapidly cooled from 800°C to 120°C. The coal material is heated to undergo low-temperature pyrolysis, and the heating rate of the coal material is between 50°C / min and 500°C / min. The temperature gradient between the cold end and the hot end is 700°C / m. The oil-gas mixture and heat carrier gas produced by pyrolysis enter the gas colle...

Embodiment 3

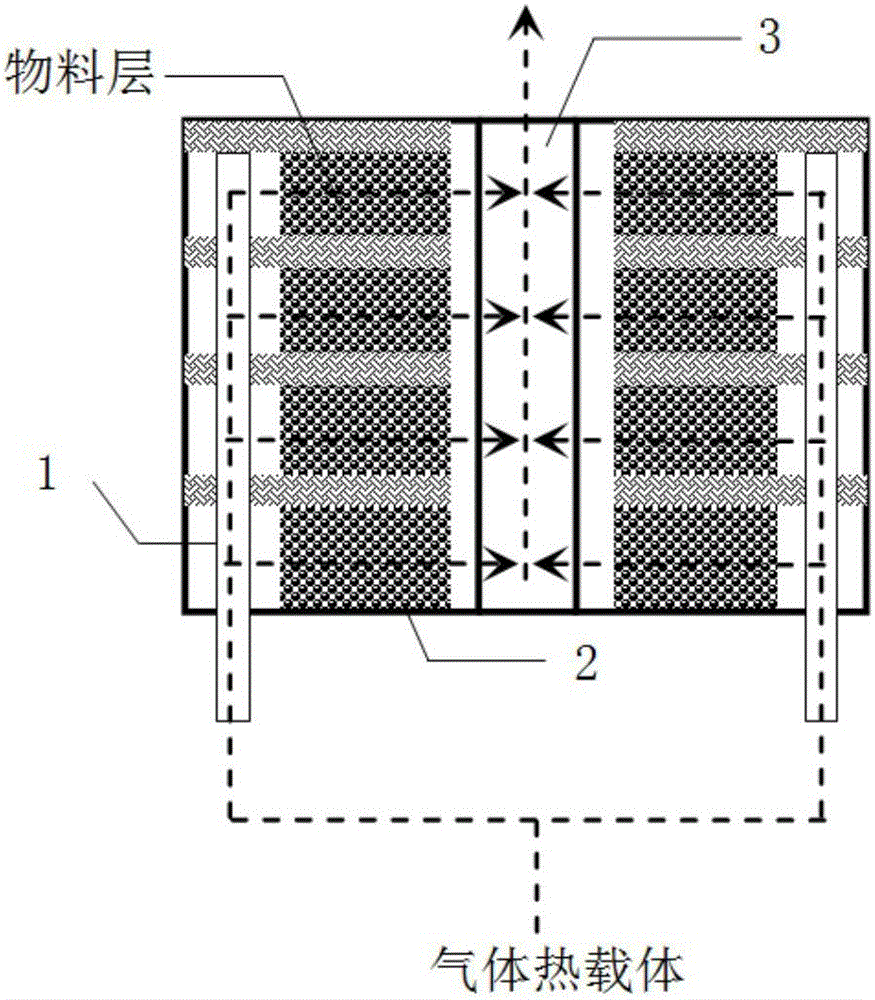

[0017] Example 3 shows the opinion image 3 . The material is oil shale. Combustion chamber 1 (hot end), carbonization chamber 2 and gas collection chamber 3 (cold end) combined units are arranged in opposite sides. In this moving bed reactor, the distance between the cold and hot ends is 60cm, the coal material moves from top to bottom, and the gas heat carrier penetrates the coal material in the carbonization chamber 2 radially from the combustion chamber 1 (hot end) and enters the gas collection In chamber 3 (cold end), the heat carrier gas and coal material undergo rapid gas-solid heat exchange, and the temperature of the gas heat carrier is rapidly cooled from 800°C to 120°C. The coal material is heated to undergo low-temperature pyrolysis, and the heating rate of the coal material is between 50°C / min and 500°C / min. The temperature gradient between the cold end and the hot end is 700°C / m. The oil-gas mixture and heat carrier gas produced by pyrolysis enter the gas col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com