Petroleum naphtha reforming catalyst and preparation method thereof

A reforming catalyst and catalyst technology, applied in the direction of naphtha catalytic reforming, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of lower reforming product liquid yield, low catalyst activity, etc., and achieve high liquid Yield and Aromatics Selectivity, Effect of High Surface Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of catalyst provided by the invention comprises the steps:

[0017] (1) Preparation of carrier: mix pseudo-boehmite and water evenly, add peptizer to obtain aluminum sol, then add complexing agent to fully react to obtain alumina gel, dry and roast the gel to obtain alumina carrier, Described complexing agent is selected from polyhydric alcohol or acetylacetone;

[0018] (2) Introduce active components into the alumina carrier prepared in step (1) by co-impregnation method or step-by-step impregnation method, then dry and calcinate to obtain a catalyst.

[0019] In the method (1), step (1) is carrier preparation, first mixing pseudo-boehmite with water, fully stirring for 1 to 24 hours, and then adding a peptizer for peptization to obtain aluminum sol. The suitable temperature for peptization is 0-95°C, and the time is preferably 2-10 hours. Described peptizer is selected from inorganic acid, preferably nitric acid, hydrochloric acid or sulfuric...

example 1

[0029] The following examples prepare the catalysts described in this invention.

[0030] (1) Preparation of carrier

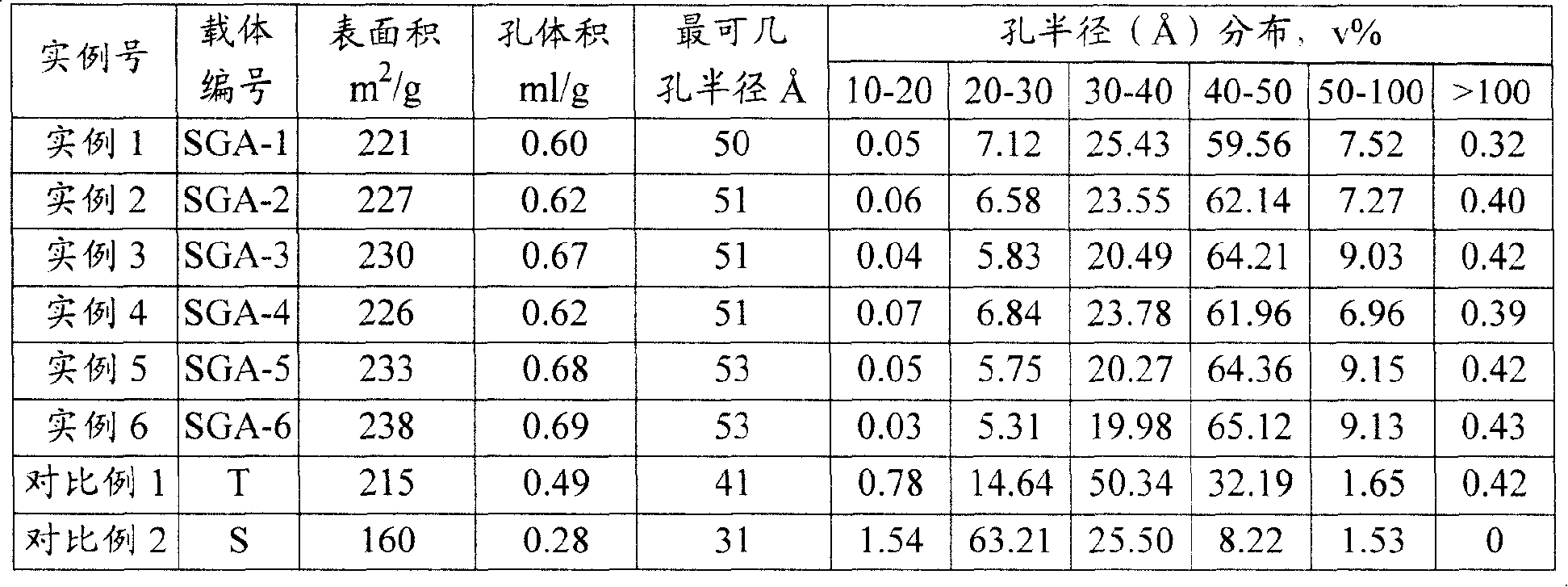

[0031] Get 140 grams of pseudo-boehmite (produced by German Sasol company, PURAL SB, aluminum oxide content 74 mass %) is put into 2 liters of reaction flasks, add 0.9 liters of deionized water, stir for 24 hours, add 100 milliliters of concentrations and be the nitric acid solution of 2 mol / liters, make the H in the system + The molar ratio of / Al was 0.1. The peptization was stirred at 85°C for 6 hours to obtain a transparent aluminum sol. Keep the temperature of the sol at 60° C., add 100 g of glycerol and stir for 1 hour to obtain a glycerol-complexed aluminum gel. The gel was dried at 80°C for 12 hours, and then calcined at 650°C in air for 4 hours to obtain the alumina support SGA-1. The surface area and pore size distribution determined by BET method are shown in Table 1.

[0032] (2) Preparation of catalyst

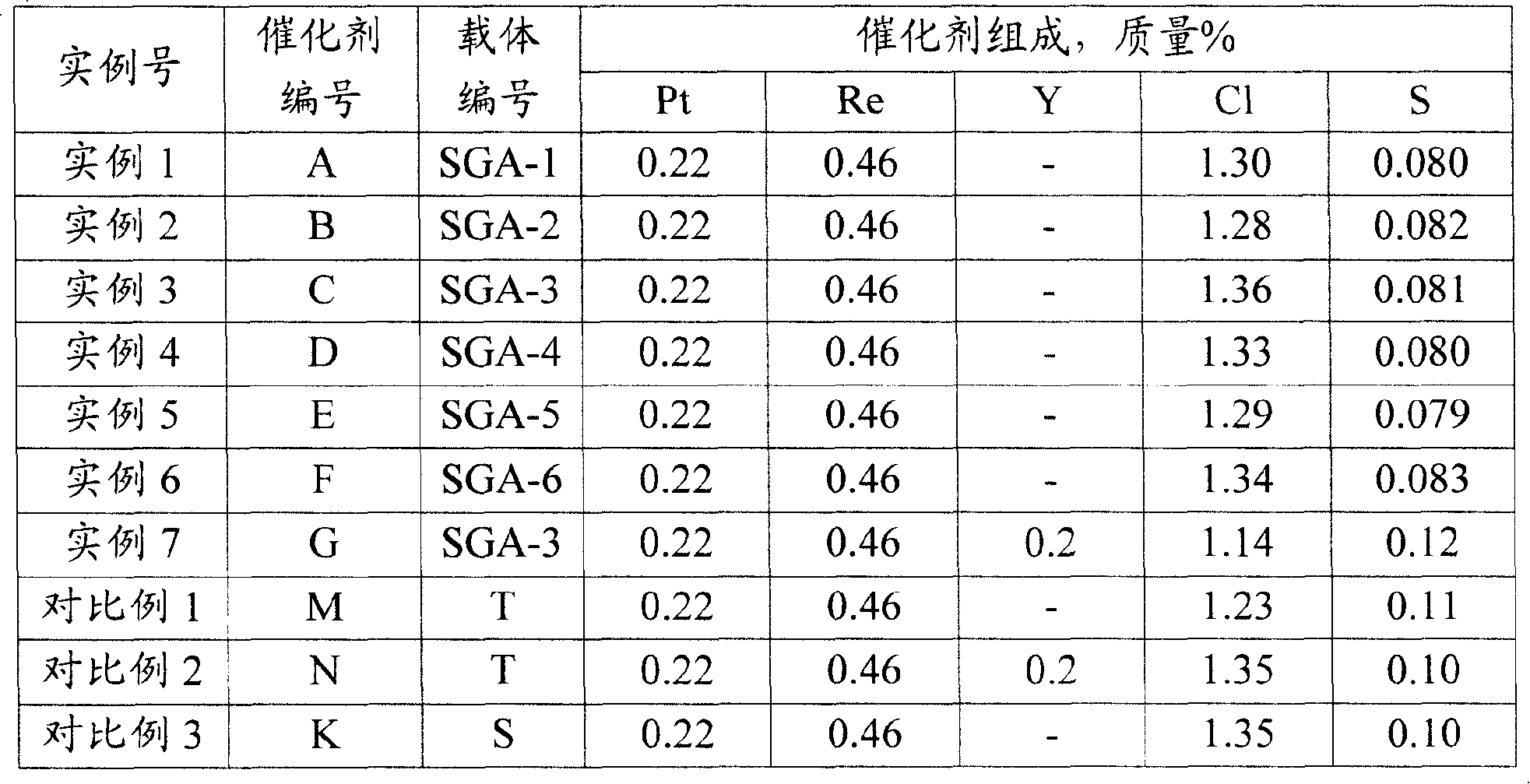

[0033] Get 60 grams of alumina carrier...

example 2

[0035] Prepare carrier by the method for example 1 (1) step, difference is in the aluminum sol that makes, add 280 gram glycerols, the surface area and the pore size distribution of the alumina carrier SGA-2 that make are shown in Table 1.

[0036] Get 60 grams of alumina carrier SGA-2, prepare catalyst by the method for example 1 (2) step, the composition of the catalyst B that obtains after the presulfurization is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com