Process for the distillation of decanted oils for the production of petroleum pitches

a technology of distillation process and petroleum pitch, which is applied in the direction of tar working up, hydrocarbon distillation control/regulation, working up pitch/asphalt/bitumen, etc., can solve the problems of not being able to achieve the efficiency of the process, and achieve excellent physical and chemical qualities, increase the yield of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

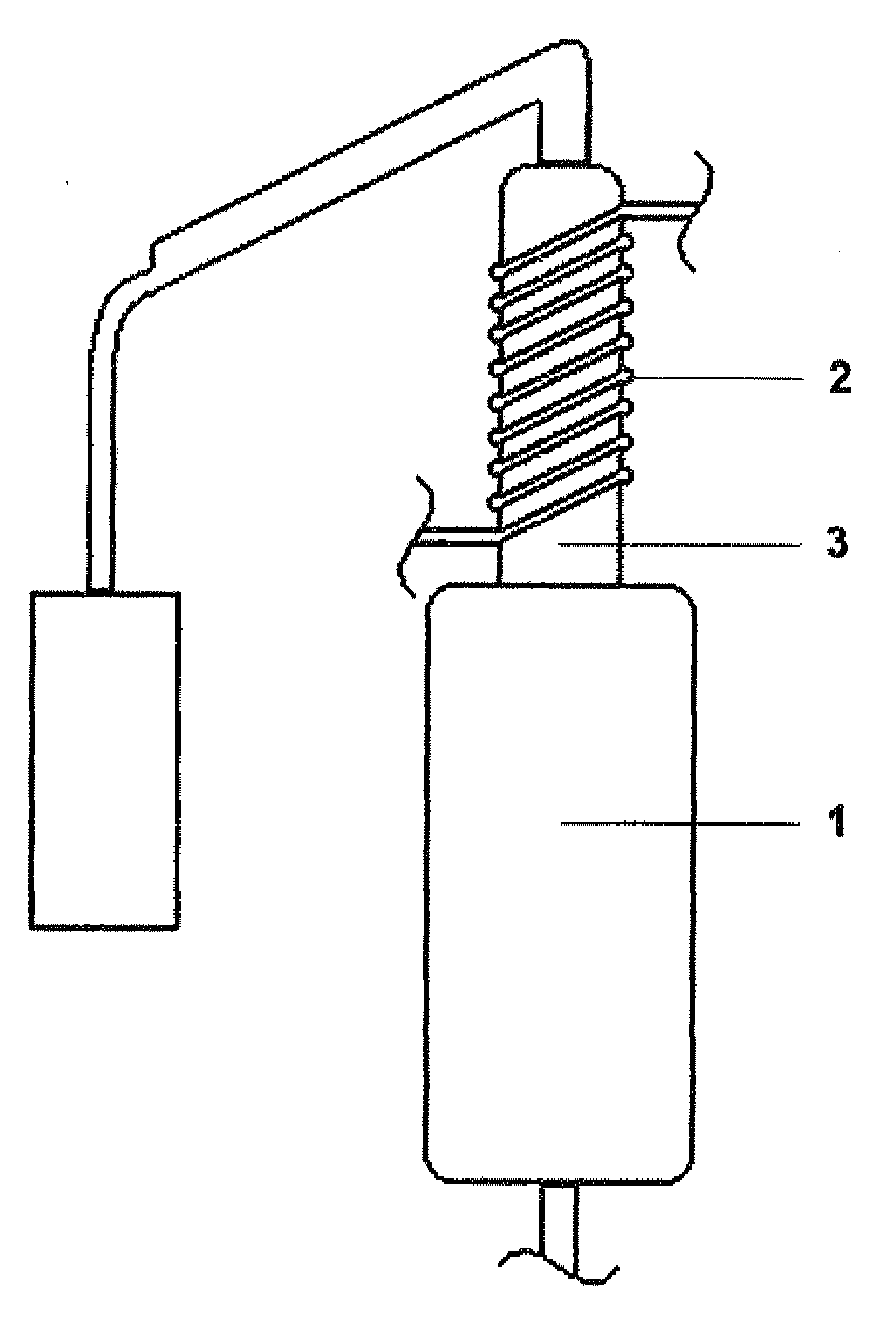

[0019]This invention relates to a process for the distillation of decanted oil with a view to increasing the production yield of pitches having excellent physical and chemical properties.

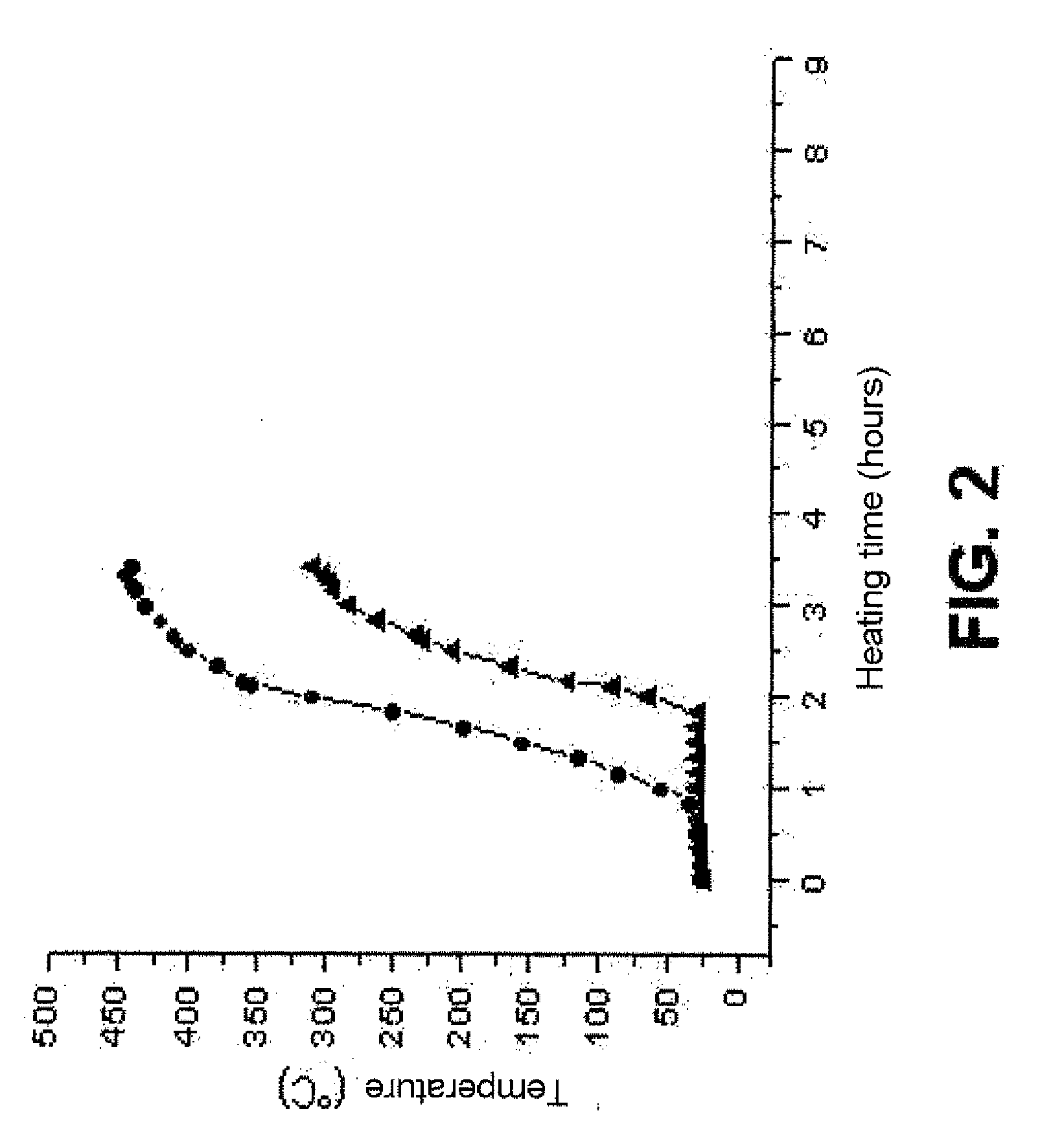

[0020]As already mentioned previously, pitches can be produced using coal tar and heavy oil residues. Heavy oil residues or residues from its processing have been widely used as a primary material for obtaining pitches. However, the majority of the technical work which uses petroleum pitch in its experiments mentions the use of commercial pitches as a raw material. The production of pitches from decanted oil as raw material involves a distillation which removes lighter compounds and makes it possible to form a heavy material, a pitch which is in the solid state at ambient temperature. The yield of pitch obtained from conventional distillation is of the order of 20%. A vacuum which although accelerating the distillation process also results in even lower yields than in the conventional process may be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com