Preparation method of Fischer-Tropsch synthesis kerosene and method for preparing semisynthetic aviation kerosene from Fischer-Tropsch synthesis kerosene

A technology of Fischer-Tropsch synthesis and aviation kerosene, which is applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc., can solve the problems of high production cost, and achieve the effects of low nitrogen content, low aromatics content and low sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of Fischer-Tropsch synthetic kerosene, the method comprises the following steps:

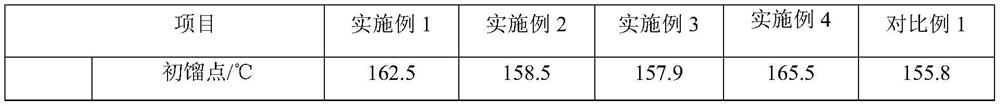

[0041] (1) Fischer-Tropsch synthetic oil undergoes hydrorefining reaction, and after fractionation of the generated hydrorefined product, the tower top and sideline products are extracted to the finished product tank area, and the hydrorefined tail oil is subjected to hydrocracking reaction; the generated hydrocracking The product enters the fractionation tower for fractionation, the diesel component of the 160-350°C fraction is extracted from the side line, the crude naphtha component of the 45-205°C fraction is extracted from the top of the tower, and the rest is hydrocracking bottom oil; hydrogenation The cracked bottom oil is subjected to hydroisomerization reaction, and the generated hydroisomerization product enters the hydrocracking fractionation tower for fractionation. By adopting the aforementioned preparation conditions, the f...

Embodiment 1

[0072] (1) Fischer-Tropsch synthetic oil (n-paraffin content 93%) passes through the hydrotreating reactor, and the catalyst is MoO 3 , the operating conditions are: reaction temperature 290°C, reaction pressure 6.8MPa, hydrogen-oil ratio 500:1, volume space velocity 2.0h -1 ; The resulting refined product is subjected to vacuum fractionation to extract the top and sideline products; the fractionation conditions are 55 trays, a reflux ratio of 0.7:1, an operating pressure of 100kPa, and a bottom temperature of 350°C;

[0073] The refined tail oil is sent to the hydrocracking reactor, the mass ratio of the hydroisomerization catalyst to the hydrocracking catalyst is 1:6, and the catalyst filling sequence includes the lower protective agent (FZC-102N), the hydroisomerization catalyst (3 wt%MoO 3 / Al 2 o 3 : 3% by weight WO 3 / Al 2 o 3 =1:1), hydrocracking catalyst (3% by weight NiO / SiO 2 : 3% by weight MoO 3 / SiO 2 =1:1) and upper protective agent (FZC-102N), the operat...

Embodiment 2

[0078] (1) get 160~350 ℃ of diesel oil cuts and 45~205 ℃ of crude naphtha cuts in embodiment 1 step (1);

[0079] (2) Distill and cut the 160-350°C diesel oil fraction and 45-205°C crude naphtha fraction obtained in step (1). The cutting conditions of the diesel oil fraction are: reflux ratio at 5:1, operating pressure: 86kPa, Heating temperature at the bottom of the tower: 280°C, cut out the 150-260°C fraction as Fischer-Tropsch synthetic kerosene component A; cutting conditions for the crude naphtha fraction: reflux ratio at 5:1, operating pressure: 86kPa, heating temperature at the bottom of the tower : 160°C, cut out the distillate >150°C as Fischer-Tropsch synthetic kerosene component B; mix Fischer-Tropsch synthetic kerosene component A and component B according to the volume ratio of 2:1, and the mixed oil is used as Fischer-Tropsch synthetic kerosene components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com