Method for continuously synthesizing 2-nitropropane by adopting slurry reactor

A nitropropane, slurry bed technology, applied in the preparation of nitro compounds, organic chemistry, chemical recovery, etc., can solve the problems of cumbersome operation, unfriendly environment, low yield, etc., and achieves simple process, convenient operation, and economical energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

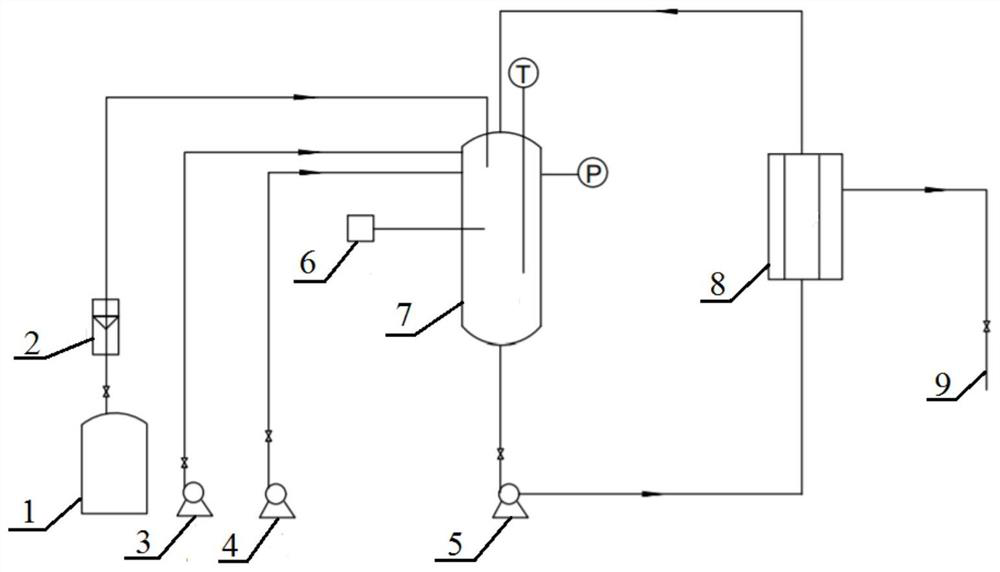

[0036] Take 200 g of the treated TS-1 catalyst and put it into a 2L slurry bed reactor, and add 1.2 L of methanol into the slurry bed reactor, raise the temperature to 70°C, and turn on the circulating pump to circulate. 200g / h acetone-methanol mixture and 212.9g / h27.5% hydrogen peroxide enter the reaction tank at the same time, and feed ammonia gas to control the pH of the reaction system=6~7, control the reaction pressure to 0.2MPa, and the total feed is in the reaction tank After staying for 3 hours, 400 g / h of the reaction solution was extracted through membrane tube separation, and the conversion rate of acetone was 95.4%, the selectivity of 2-nitropropane was 99.6%, and the yield was as high as 95.2%.

Embodiment 2

[0038] Take 200 g of the treated TS-1 catalyst and put it into a 2L slurry bed reactor, and add 1.2 L of methanol into the slurry bed reactor, raise the temperature to 75°C, and turn on the circulation pump to circulate. 200g / h acetone-methanol mixture and 212.9g / h27.5% hydrogen peroxide enter the reaction tank at the same time, and feed ammonia gas to control the pH of the reaction system=6~7, control the reaction pressure to 0.2MPa, and the total feed is in the reaction tank After staying for 5 hours, 400 g / h of the reaction solution was extracted through membrane tube separation, and the conversion rate of acetone was 97.4%, the selectivity of 2-nitropropane was 99.2%, and the yield was as high as 96.8%.

Embodiment 3

[0040] Take 200 g of the treated TS-1 catalyst and put it into a 2L slurry bed reactor, and add 1.2 L of methanol into the slurry bed reactor, raise the temperature to 70°C, and turn on the circulating pump to circulate. 200g / h acetone-methanol mixture and 255.7g / h27.5% hydrogen peroxide enter the reaction tank at the same time, and feed ammonia gas to control the pH of the reaction system=6~7, control the reaction pressure to 0.2MPa, and the total feed is in the reaction tank After staying for 4 hours, 400 g / h of the reaction liquid was extracted through membrane tube separation, and the conversion rate of acetone was 99.1%, the selectivity of 2-nitropropane was 99.5%, and the yield was as high as 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com