Method for orderly rectifying and separating nitromethane-nitroethane-nitropropane by continuous three towers

A technology of nitropropane and nitromethane, which is applied in the field of continuous three-tower sequential distillation and separation of nitromethane-nitroethane-nitropropane, which can solve the problem of low market demand, no large-scale production, and complicated operation process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with specific embodiment, described embodiment helps to the understanding and implementation of the present invention, does not constitute limitation of the present invention, implements the present invention, except the material involved in the specific embodiment and rectifying operation In addition to conditions, those skilled in the art can also perform equivalent or equivalent transformations according to different separation purposes. The protection scope of the present invention is not limited by the specific embodiments, but by the claims. Unless otherwise specified, the percentages in the present invention are all mass percentages.

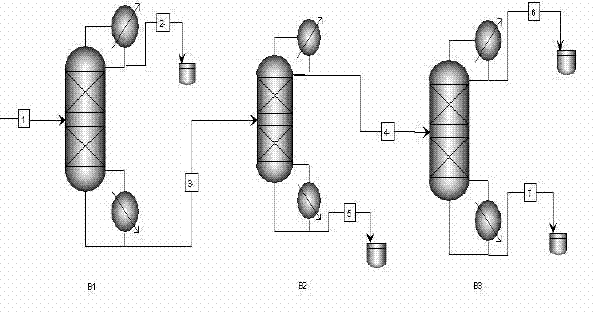

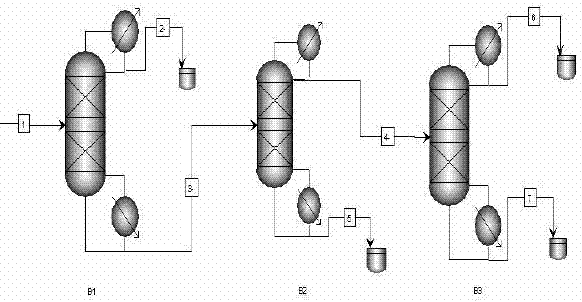

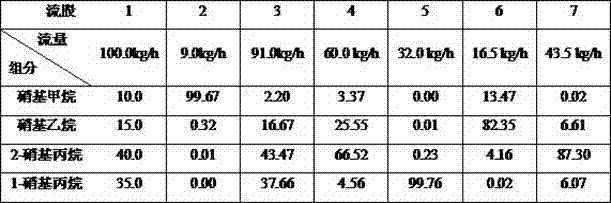

[0020] A method for the sequential rectification of three consecutive towers to separate nitromethane-nitroethane-nitropropane, refer to figure 1 Shown technology and parameter shown in table 2, raw material (1) is the mixed liquor of nitromethane, nitroethane, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com