Patents

Literature

43 results about "2-Nitropropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Nitropropane (2-NP) is a solvent. It is a colorless liquid and is classified as a nitro compound.

Process for the manufacture of nitropropanes

ActiveUS20110028731A1Increase conversionsHigh yieldAmino compound purification/separationOrganic compound preparationNitrationPropane

Provided is a process for the formation of 2-nitropropane and / or 2,2-dinitropropane by the nitration of propane with dilute nitric acid.

Owner:ANGUS CHEM CO

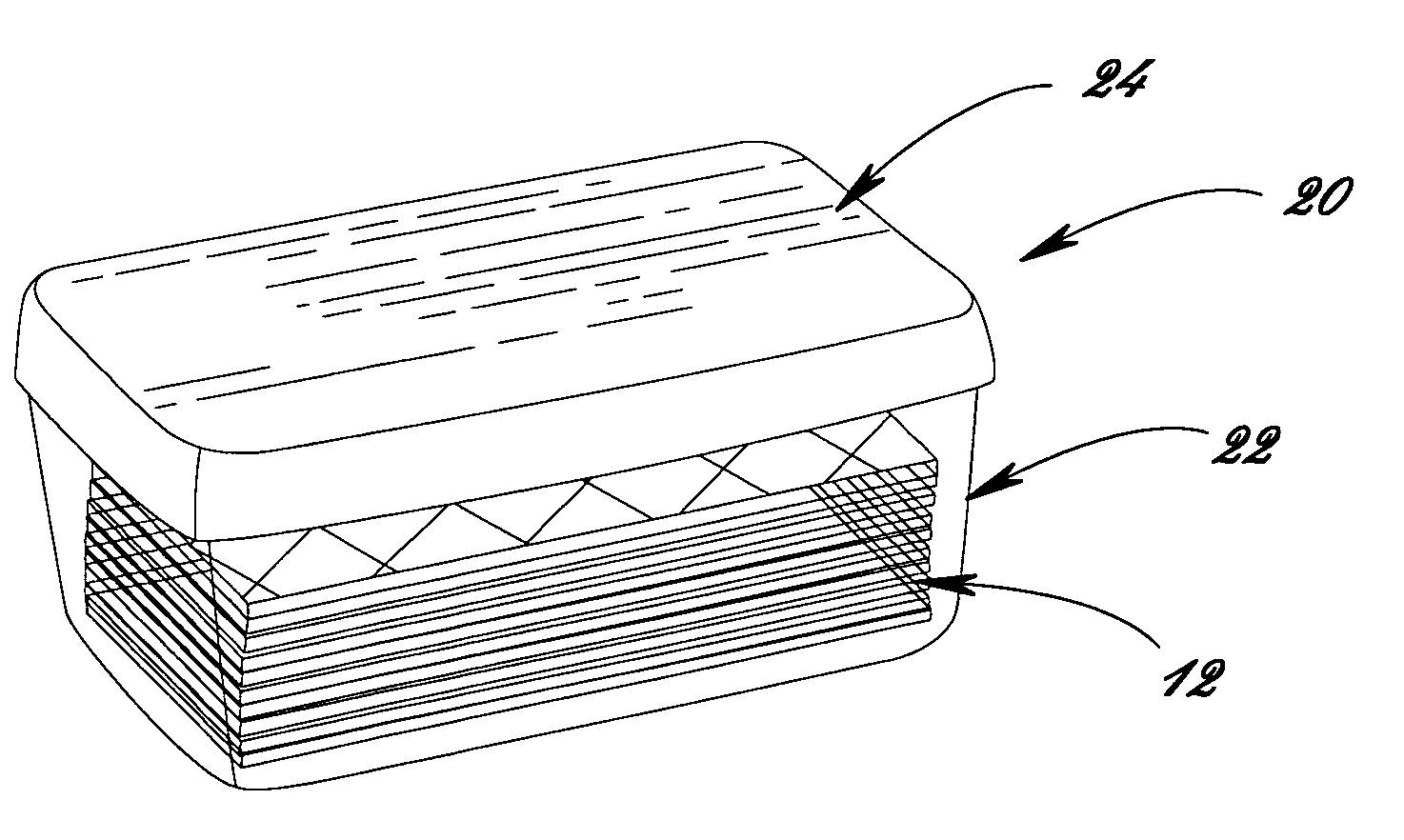

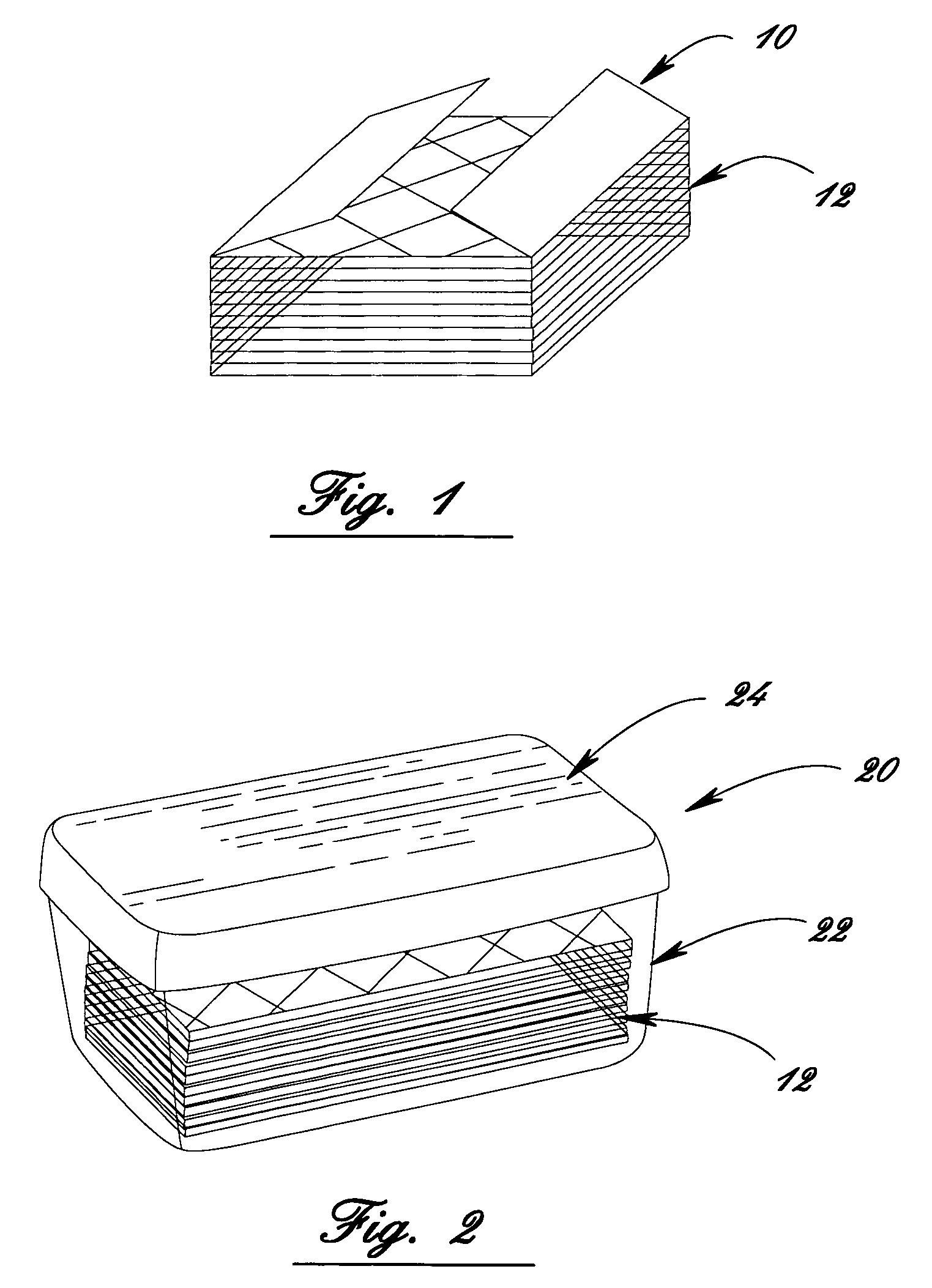

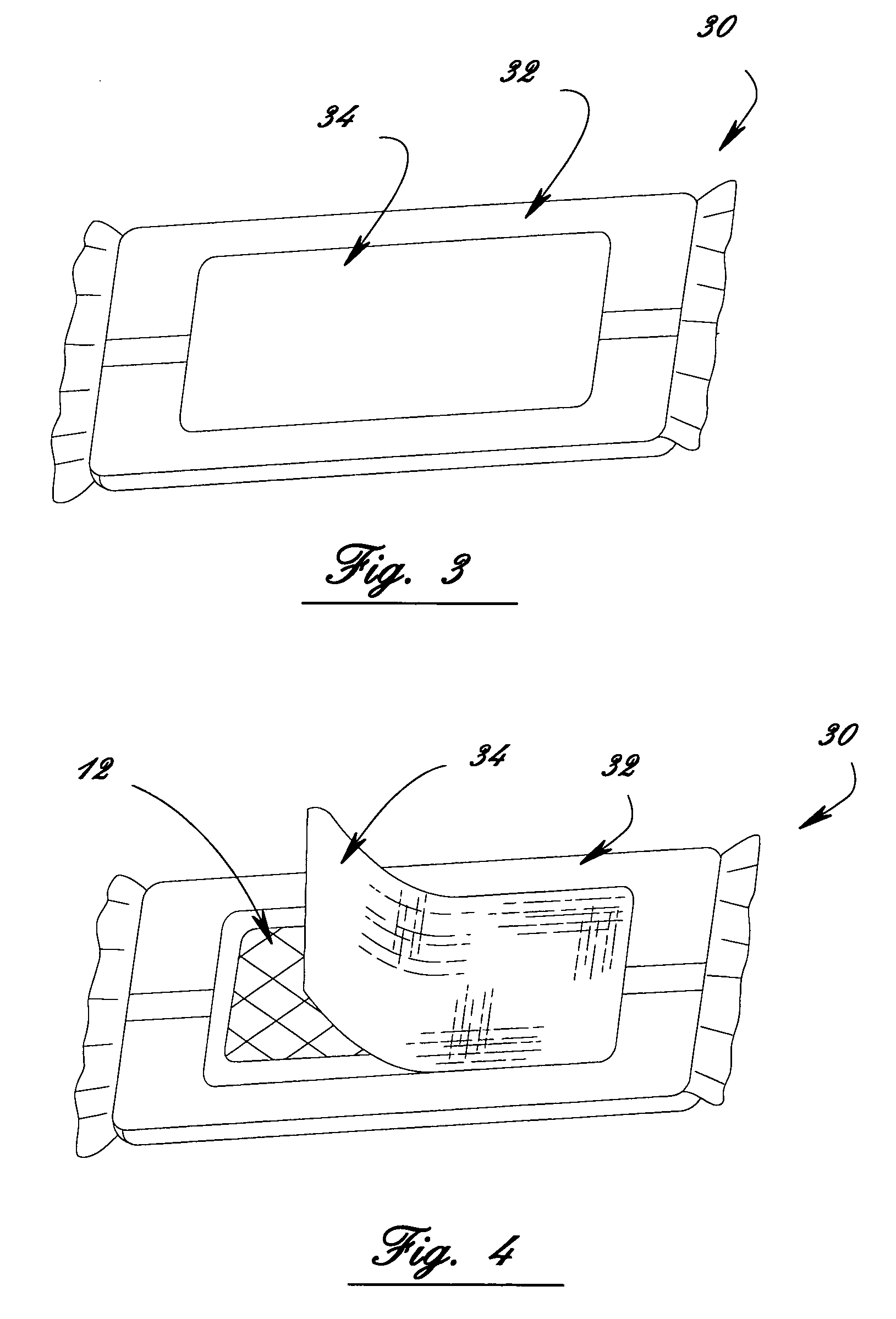

Sheet substrates impregnated with aromatic releasing compositions and a method of delivery of aromatic releasing compositions

An article of manufacture and a method directed to application of aromatic releasing compositions impregnated within substrates such as non-woven paper materials (e.g., wipes, paper towels) and dispensable cloth materials (e.g., gauze or a thin fabric of silk, linen, or cotton materials) for providing relief from cold, allergies, sinus and symptoms associated with respiratory disorders, the aromatic releasing compositions including the following: Menthol; Camphor; Eucalyptus oil; Cedarleaf Oil; Myristica Oil; Peppermint Oil; Lavender oil; Methyl Salicylate; Naproxen; Nutmeg Oil and Thymol; Beclometasone dipropionate; Benzethonium chloride with base solution consisting of Emollients, Emulsifiers and Moisturizer; Deionized Water; Vegetable Oil; Dicaprylyl Carbonate; Glyceryl Oleate; Polyglyceryl-2 Dipolyhydroxystearate; Cetearyl Isononanoate; Ceteareth-20; Cetearyl Alcohol; Glyceryl Stearate; Glycerin; Cetyl Palmitate; Ceteareth-12, Lauryl Glucose Carboxylate; Lauryl Glucoside; Sodium Citrate; Citric Acid; Benzethonium Chloride 0.05%; Ethylene diamine tetra acetic acid; Phenoxyethanol; Methylparaben; Propylparaben; 2-bromo-2-nitropropane-1,3-diol; and subcombinations thereof. In further embodiments, the compositions impregnated within substrate further include one or more topical actives, and are useful for providing relief from cold, allergies, sinus and symptoms associated with respiratory disorders, as well as repelling common virus and bacteria.

Owner:ADELAKUN OLUFEMI

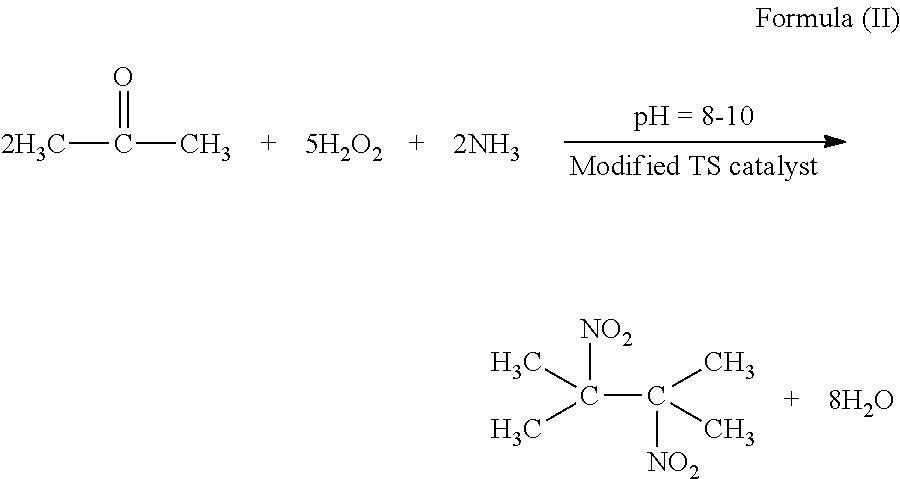

Method for preparing 2-nitropropane

InactiveCN106045859AImprove conversion rateHigh selectivityOrganic compound preparationNitro compound preparationMolecular sieveReaction temperature

The invention discloses a method for preparing 2-nitropropane, and relates to the technical field of organic compound synthesis. The method comprises the following steps: enabling acetone, ammonia gas or ammonia water, hydrogen peroxide, a solvent and a catalyst to contact, heating till the reaction temperature of 30-100 DEG C, and controlling the reaction pressure to 0.1-0.2MPa to react, thereby obtaining 2-nitropropane, wherein the catalyst is a TS-1 titanium silicalite molecular sieve; the solvent is water; the mole ratio of acetone to ammonia gas or ammonia water is 1:(1-3); the mole ratio of acetone to hydrogen peroxide is 1:(0.5-2); and the mass ratio of acetone to the catalyst is 1:(0.2-0.4). The method disclosed by the invention has the advantages that the conversion rate of acetone is high and the selectivity of 2-nitropropane is good; the method is simple in reaction process, gentle in reaction condition, environment-friendly and easy in industrial production; and development of environment-friendly chemicals is promoted.

Owner:定州旭阳科技有限公司

Steam condensate corrosion inhibitor compositions and methods

ActiveUS20050121650A1Scale removal and water softeningWater/sewage treatment by substance additionPreservativeDiol

Lecithin and 2-bromo-2-nitropropane-1,3 diol (BNPD) are used to inhibit corrosion in boiler steam condensate systems. Aqueous steam condensate corrosion inhibiting compositions of these components are also disclosed. BNPD is also used as a preservative in lecithin containing and in other GRAS additive containing compositions.

Owner:BL TECH INC

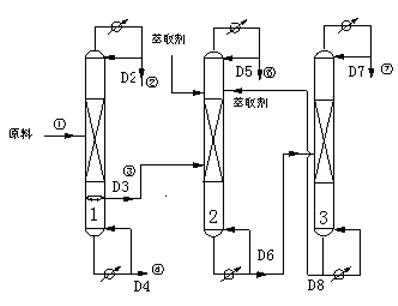

Method for separating nitroethane and 2-nitropropane by combined process of continuous side distillation and extractive distillation

InactiveCN102219699AIncrease contentImprove separation efficiencyOrganic chemistryOrganic compound preparationNitroethaneExtractive distillation

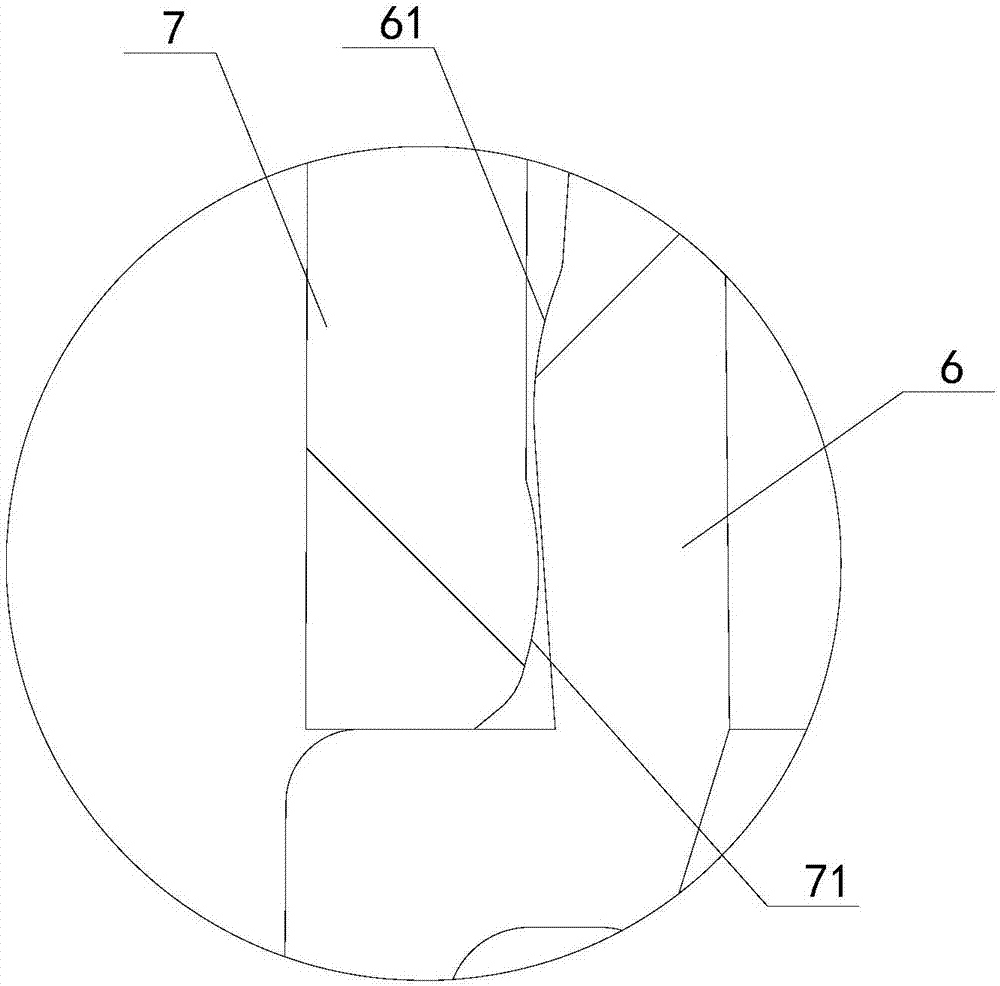

Disclosed is a method for separating nitroethane and 2-nitropropane by a combined process of continuous side distillation and extractive distillation. The method comprises the following steps: (1) adding mixed nitroparaffin1 containing 80% to 85% of nitroethane into a continuous side distillation tower so as to obtain a fraction 2 with a boiling range of 105.0 to 106.5 DEG C, a fraction 3 with a boiling range of 116.2 to 117.7 DEG C and a fraction 4 with a boiling range of 123.4 to 125.7 DEG C, wherein the content of nitroethane in the fraction 3 is over 95.5%; (2) allowing the fraction 3 to enter into an extractive distillation tower so as to obtain a fraction 5 containing over 99.4% of nitroethane in the top of the tower and a fraction 6 containing an extracting solvent and 2-nitropropane in the bottom of the tower; (3) treating the fraction 6 in a solvent recovery column and allowing the obtained extracting solvent in the column bottom to flow into the extractive distillation tower for cyclic utilization. According to the invention, the combined process of continuous side distillation and extractive distillation is employed; the process is simple and has high separation efficiency; energy consumption in the separating process is substantially reduced, and therefore production cost is saved.

Owner:江苏沿江化工资源开发研究院有限公司

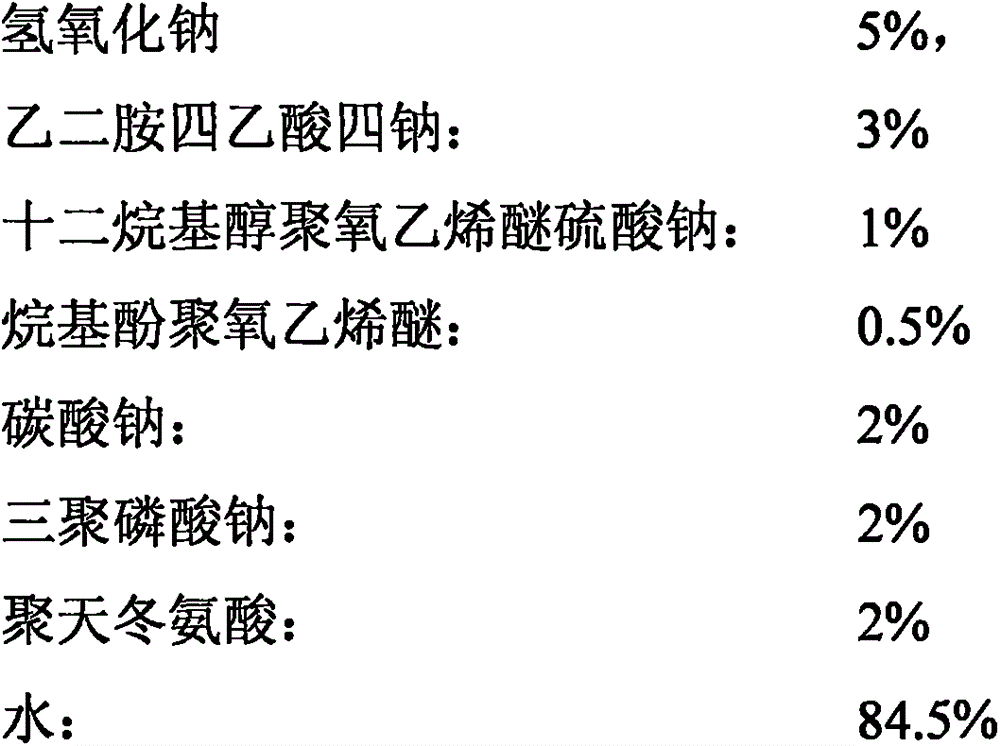

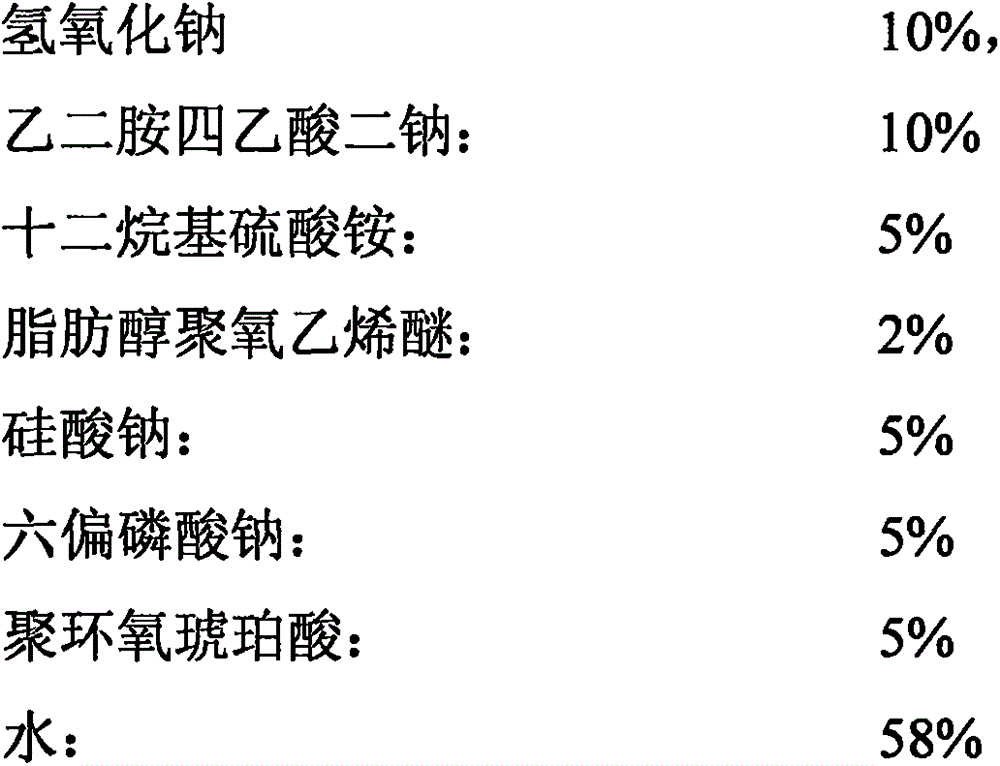

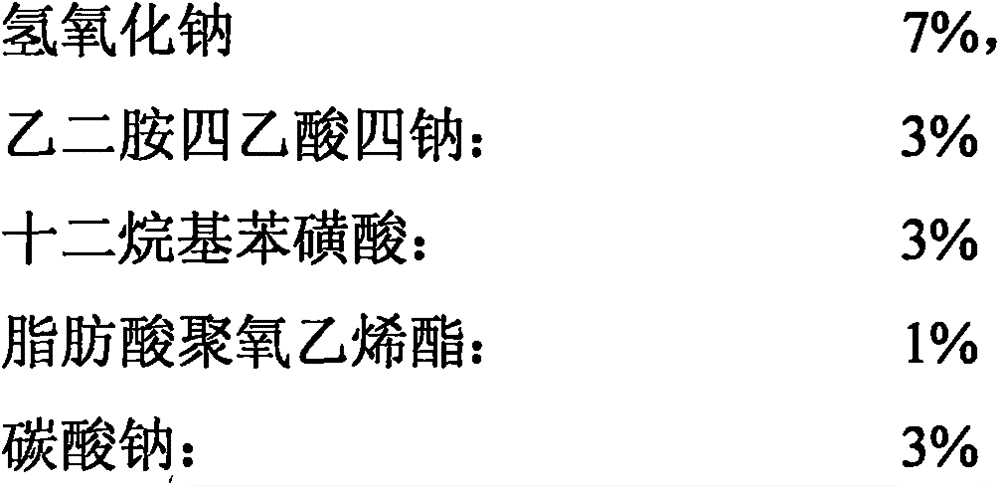

Membrane-cleaning protective agent

InactiveCN106178965ASolve puzzlesReverse osmosis desalination rate does not decreaseSemi-permeable membranesGeneral water supply conservationPhosphatePolyhexamethylene guanidine

The invention discloses a membrane-cleaning protective agent. The membrane-cleaning protective agent comprises an alkaline membrane-cleaning agent and a membrane-cleaning bactericide, wherein the alkaline membrane-cleaning agent comprises the following components of: caustic soda, chelating agent, anionic surfactant, non-ionic surfactant, salt, phosphate, amino acid polymer and water; the membrane-cleaning bactericide comprises the following components of: polyhexamethylene guanidine and 2-bromo-2-nitropropane-1,3-glycol. The membrane-cleaning protective agent disclosed by the invention has the advantages that not only can the pollutants on the membrane be thoroughly removed, but also the advantage of no reduction of reverse-osmosis desalination rate of the membrane after cleaning can be guaranteed, the difficulty of reduction desalination rate of the membrane in the membrane-cleaning industry is solved and the blank of the membrane-cleaning industry in China is made up.

Owner:常州联江环保科技有限公司

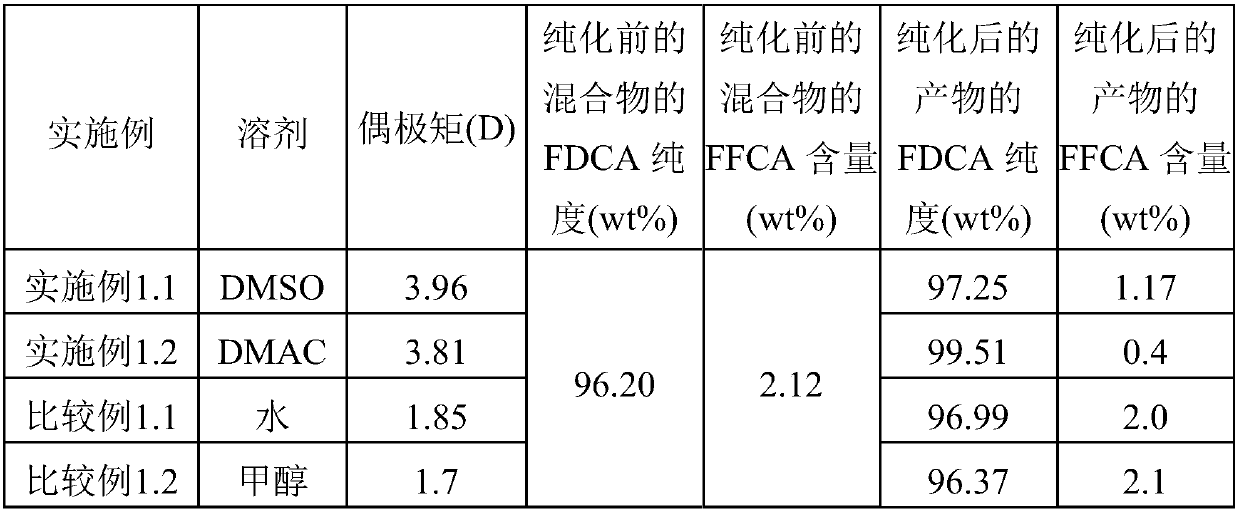

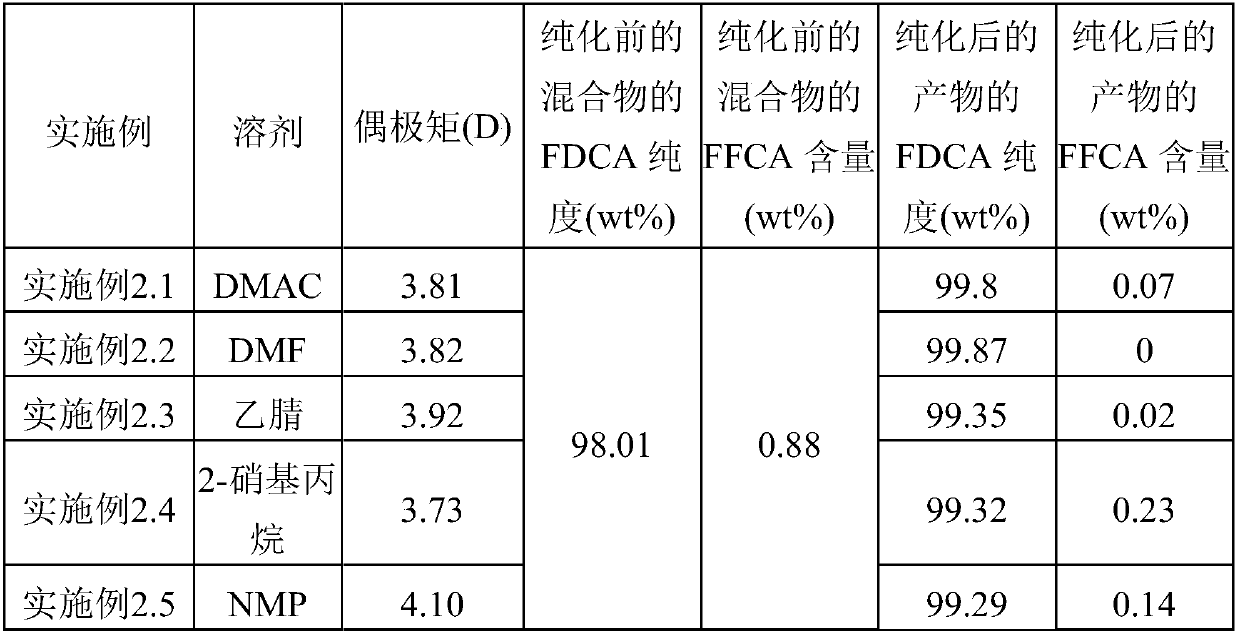

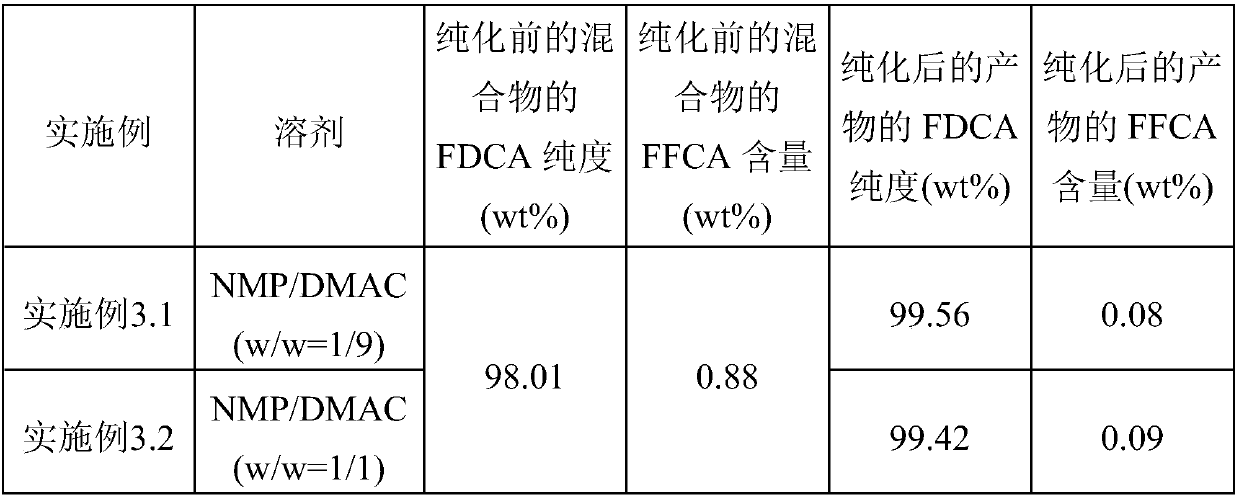

Method for purifying crude 2,5-furandicarboxylic acid by crystallization

Method for purifying a crude of 2,5-furandicarboxylic acid (cFDCA) by crystallization is provided. The method includes (a) mixing the cFDCA and a solvent to form a mixture, wherein the solvent includes dimethyl acetamide, acetonitrile, dimethylformamide, 2-nitropropane, N-methyl-2-pyrrolidone, or a combination thereof; (b) heating the mixture; (c) after step (b), cooling the mixture to precipitatea solid; and (dl) after step (c), filtering the mixture to collect a wet filter cake of the solid, and drying the wet filter cake to obtain purified FDCA. The purified FDCA has a higher FDCA purity than that of the cFDCA. The method for purifying a crude of 2,5-furandicarboxylic acid (cFDCA) by crystallization is simple and mild.

Owner:IND TECH RES INST

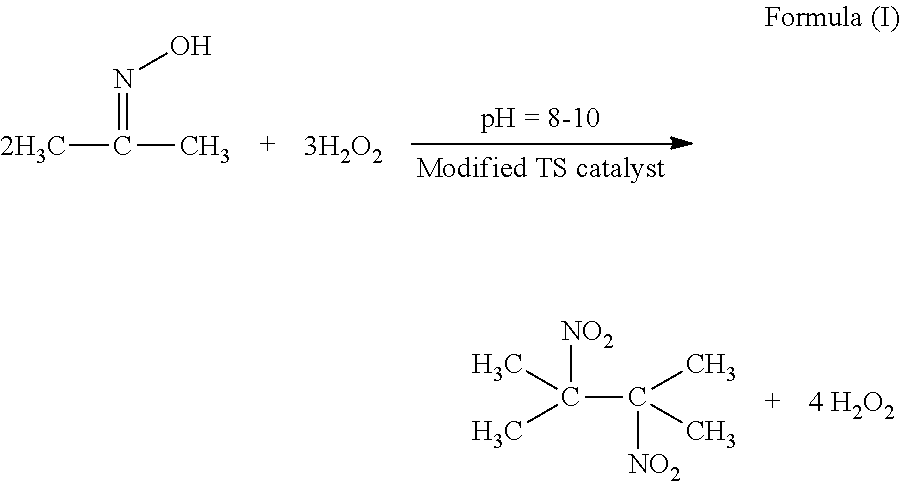

Synthesizing method of 2-nitropropane

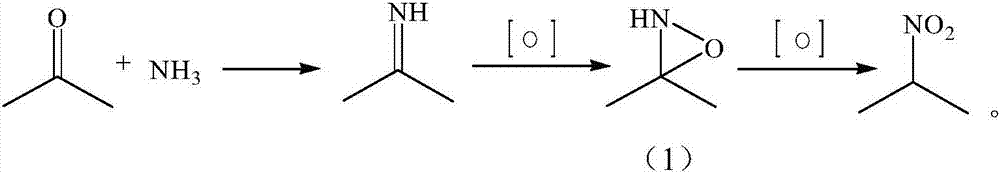

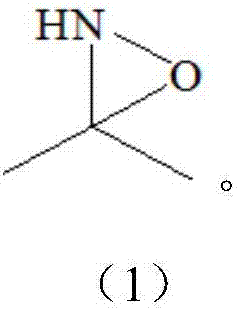

ActiveCN106986772AMild reaction conditionsSimple processOrganic compound preparationImino compound preparationMass ratioCatalytic oxidation

The invention discloses preparation of substituted saturated hydrocarbon and particularly relates to a synthesizing method of 2-nitropropane. The 2-nitropropane is prepared by oxidizing isohydrazone. The synthesizing method includes the steps of S1, condensing acetone, water and ammonia in the presence of a catalyst to generate ketimine, wherein the mass ratio of the acetone to the water is 1:(1-5), and the use amount of the catalyst is 5-11% of the use amount of the acetone; S2, oxidizing the ketimine obtained in the step S1 to form the isohydrazone, wherein reaction system temperature is 30-60 DEG C and heat-preservation reaction time is 0.5-3 hours; S3, oxidizing the isohydrazone obtained in the step S2 to form the 2-nitropropane, wherein reaction system temperature is 50-80 DEG C and heat-preservation reaction time is 0.5-3 hours; rectifying obtained primary reaction liquid to obtain qualified 2-nitropropane products. The synthesizing method has the advantages that the acetone, the ammonia and the water are used as the initial raw materials, and the method is mild in catalytic oxidizing reaction condition, simple in process, convenient to operate, suitable for large-batch 2-nitropropane production, simple in post-processing and high in product purity and does not coproduce acetone oxime or acetone azine.

Owner:宁波四明化工有限公司

Novel synthesis method of florfenicol

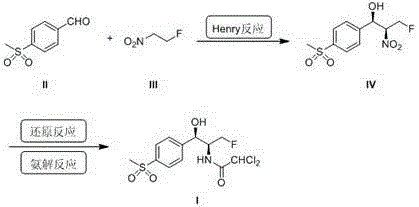

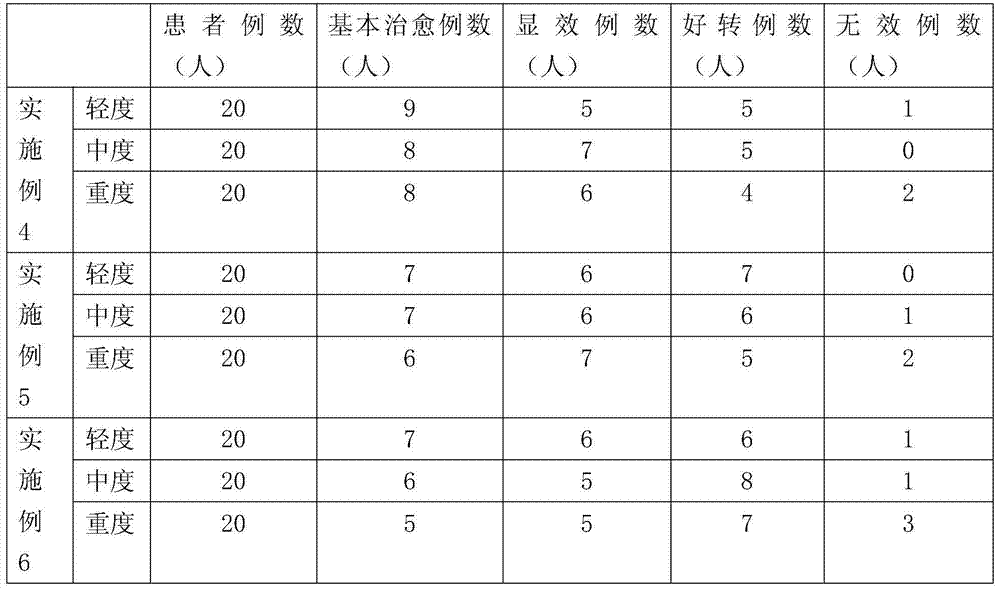

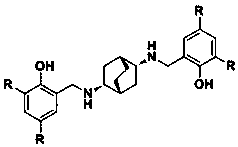

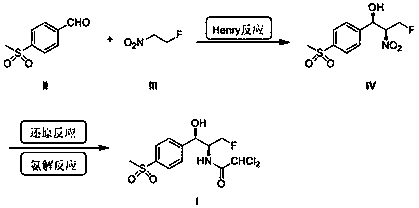

ActiveCN106349130ANo burdenReduce processing costsOrganic chemistryOrganic compound preparationBenzeneBenzaldehyde

The invention provides a synthesis method of florfenicol (I). The method is characterized by comprising the step of asymmetric Henry reaction: carrying out asymmetric Henry reaction on p-methylsulfuryl benzaldehyde (II) and fluoronitroethane (III) in a catalytic liquid to generate (1R,2S)-3-fluoro-1-(4-(methylsulfuryl)phenyl)-2-nitropropane-1-ol (IV). The florfenicol synthesis process does not increase the burden to the environment, and can save the pollutant treatment cost. In the florfenicol synthesis process, the reaction step is simple, thereby greatly lowering the cost. In the florfenicol synthesis process, the used catalyst is accessible, and the yield is higher.

Owner:WEIFANG DAYOU BIOLOGICAL CHEM CO LTD

Green plum extreme-moistening moisturizing facial mask and making method thereof

ActiveCN107213083AGood moisturizing effectMaintain humidityCosmetic preparationsToilet preparations2-NitropropaneEssence oil

The invention discloses a green plum extreme-moistening moisturizing facial mask and a making method thereof. The green plum extreme-moistening moisturizing facial mask consists of the following components: a green plum active extract, propylene glycol, butanediol, glycerinum, rosa damascena flower water, aloe vera leaf juice, hydrolyzed jojoba esters, phenoxyethanol, methylparaben and 2-bromine-2-nitropropane-1,3-diol mixed liquid, allantoin, chondrus crispus powder, an acrylic acid (ester) type / C10-30 alkanol acrylic ester cross-linking polymer, triethanolamine, EDTA (Ethylene Diamine Tetraacetic Acid) disodium, PEG-40 hydrogenated castor oil, essential oil and water. The green plum extreme-moistening moisturizing facial mask disclosed by the invention is capable of effectively and safely improving skin activity, promoting skin metabolism, promoting new skin cell generation and reducing melanin, and has remarkable effects on facial skin whitening, inflammation elimination, moisturizing and the like.

Owner:ZHANGPU CAILUHUA COSMETICS

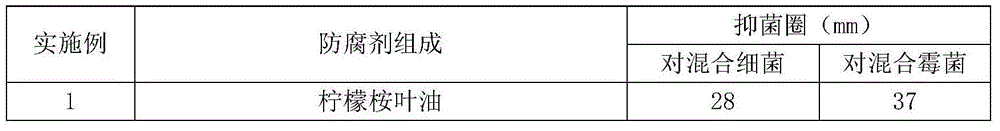

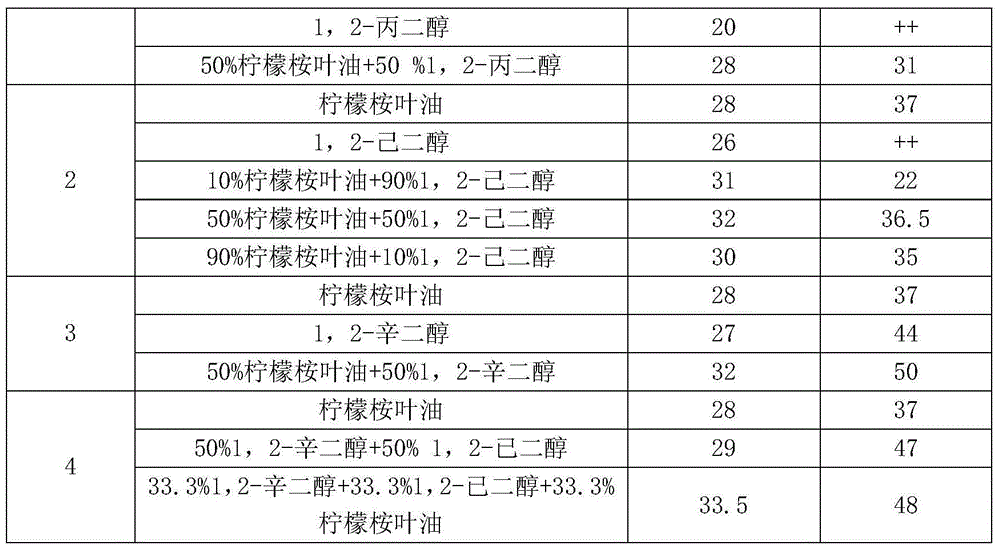

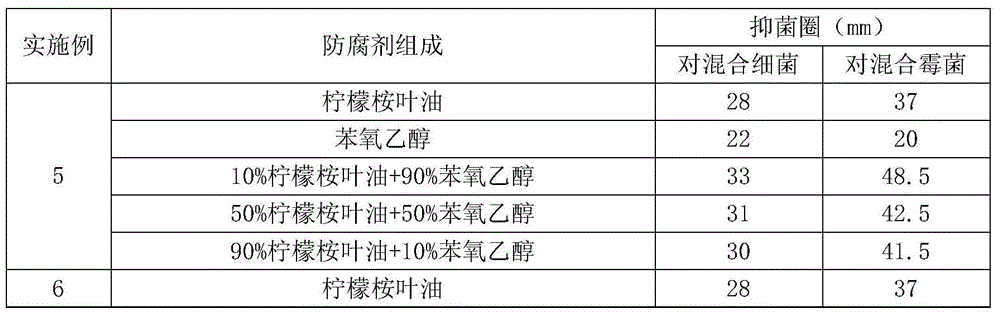

Bacteriostatic preservative composition and cosmetic composition comprising same

ActiveCN105310903AReduce the risk of adverse reactionsAvoid or reduce the concentrationCosmetic preparationsHair cosmeticsCarbon numberBenzoic acid

The invention discloses a bacteriostatic preservative composition and a cosmetic composition comprising same. The bacteriostatic preservative composition includes oil of eucalyptus citriodora leaves and at least one additive selected from the following components: 1,2-alkylglycol being 3-10 in carbon number, phenoxyethanol, benzyl alcohol, chlorphenesin, ethylhexyl glycerin, p-hydroxybenzoic acid and salts and esters thereof, benzoic acid and salts and esters thereof, sorbic acid and salts thereof, iodopropynyl butylcarbamate, imidazolidinyl urea and bis(hydroxymethyl)imidazolidinyl urea, polyaminopropyl biguanide, DMDM hydantoin, 2-bromo-2-nitropropane-1,3-diol, methyl isothiazolinone, methyl chloroisothiazolinone or a mixture of the components. The bacteriostatic preservative composition significantly improves mildew-proof and anti-bacterial performance.

Owner:SHANGHAI LIGHT IND RES INST

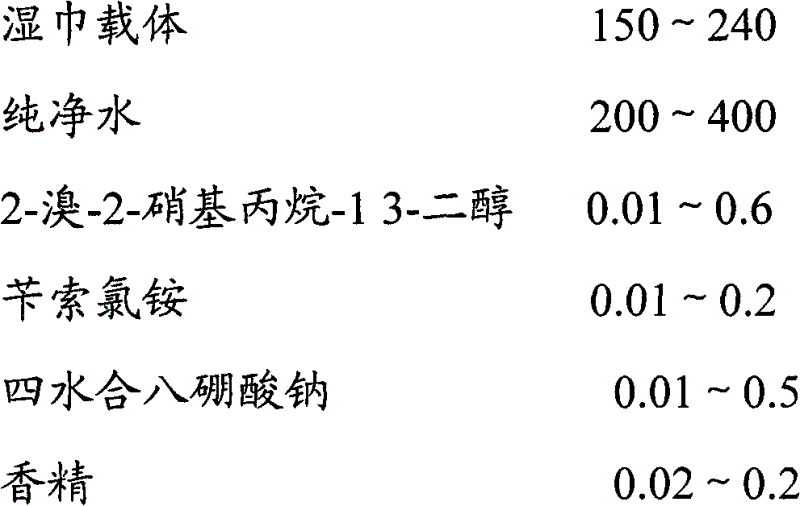

Aromatic disinfectant wet wipes and preparation method thereof

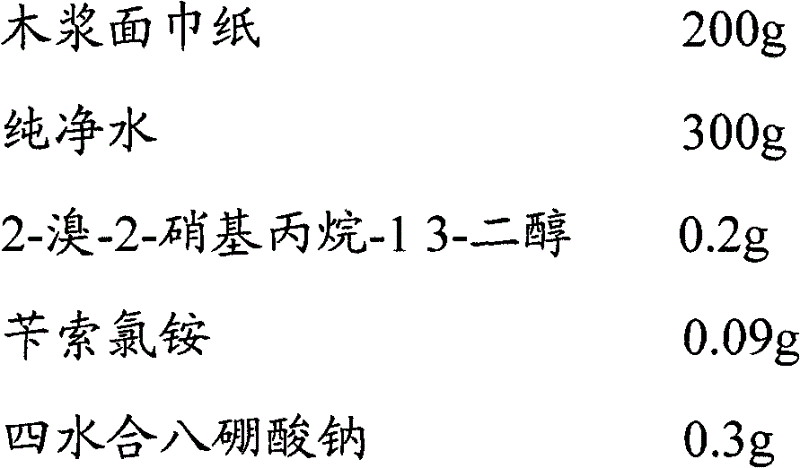

The invention belongs to the field of chemical engineering, and particularly relates to aromatic disinfectant wet wipes and a preparation method thereof. The preparation method comprises the following steps that 2-bromo-2-nitropropane-1,3-propanediol, benzethonium chloride, disodium octaborate tetrahydrate and essence with fixed quantities are produced into disinfectant mixed solution, then the disinfectant mixed solution is dropped onto a piece of carrier towel to wet the carrier towel, the dropping quantity of the disinfectant mixed solution is counted as 1.5ml per gram of the towel, and the aromatic disinfectant wet wipe can be obtained after the towel is wetted. The aromatic disinfectant wet wipes can realize high-efficient and safe sterilization, are toxic-free and harmless to the human body, have a pleasant fragrance, are convenient to carry, can be stored for a long time, are low in price, are suitable for being used in fields such as hotels, restaurants and families and are ideal disinfectant products for outworkers and financial and accountancy personnel to use every day.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

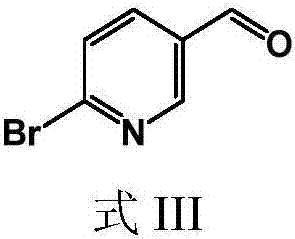

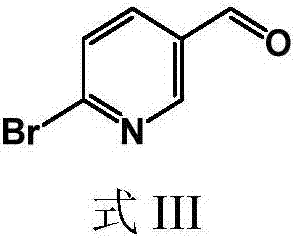

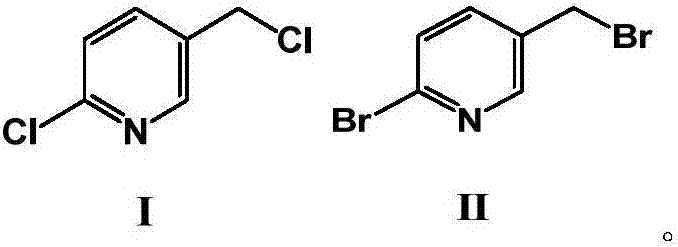

Preparation method of 6-bromopyridine-3-carboxaldehyde

The invention relates to the field of fine chemical engineering, in particular to a preparation method of 6-bromopyridine-3-carboxaldehyde. The preparation method of 6-bromopyridine-3-carboxaldehyde comprises steps as follows: 2-chloro-5-chloromethylpyridine is subjected to a bromination reaction in the presence of a bromination reagent, and 2-bromo-5-bromomethylpyridine is prepared; 2-bromo-5-bromomethylpyridine is subjected to an oxidation reaction in 2-nitropropane in the presence of alkali, and 6-bromopyridine-3-carboxaldehyde is prepared. According to the provided preparation method, 2-chloro-5-chloromethylpyridine is taken as a raw material, and 6-bromopyridine-3-carboxaldehyde is prepared through the reaction including two steps: bromination and oxidation, a process is simple to operate, the reaction conditions are mild and safe, the cost of raw materials is low, the reaction conversion rate is high, the yield is high, the product is easy to extract, and the method is more suitable for industrial safety production and has higher implementation value and social and economic benefits.

Owner:SHANGHAI CHEMSPEC CORP

Plant enzyme cleaning bubble liquid preparation

InactiveCN108498447ARefreshing skinEasy to cleanCosmetic preparationsToilet preparationsBetaineCocoyl glutamate

The invention discloses a plant enzyme cleaning bubble liquid preparation which is prepared from the following components in parts by weight: 20-60 parts of glycerin, 10-40 parts of disodium cocoyl glutamate, 20-60 parts of coco fatty acid diethanol amide propyl betaine, 10-20 parts of coco fatty acid diethanol amide DEA, 5-20 parts of flos lonicerae extract, 5-20 parts of fructus cnidii extract,5-20 parts of radix sophorae flavescentis extract, 5-20 parts of herba portulacae extract, 5-20 parts of oat extract, 3-10 parts of lipase, 10-20 parts of bromelain, 5-15 parts of bacillus fermentation product, 5-15 parts of citric acid, 0.5-5 parts of 2-bromo-2-nitropropane-1,3-diol, 0.5-5 parts of methylisothiazolinone, 1-5 parts of rose essence and 300-600 parts of water. The invention also discloses a preparation method and application of the liquid preparation. The plant enzyme cleaning bubble liquid preparation has remarkable beverage removing and wrinkle reducing effects.

Owner:广州保妈优健康产业有限公司

Massaging conditioning water applied after cleansing face and preparation method of massaging conditioning water

InactiveCN105078818AAuxiliary anti-inflammatoryAuxiliary antioxidantCosmetic preparationsToilet preparationsSterile environmentGlycerol

The invention discloses massaging conditioning water applied after cleansing face and a preparation method of the massaging conditioning water, and belongs to the field of cosmetics. The massaging conditioning water is prepared from the following raw materials: water, propylene glycol, glycerol, hydroxyethylurea, PCA sodium, a hamamelis extract, sodium hyaluronate, sodium polystyrenesulfonate, polydimethylsiloxane, a stephania tetrandra extract, triphosadenine, butanediol, phenoxyethanol, ethylparaben, methylparaben, disodium ethylene diamine tetraacetate (EDTA), 2-bromo-2-nitropropane-1,3-diol, methyl chloroisothiazolinone, methylisothiazolinone and PEG-40 hydrogenated castor oil; and the massaging conditioning water applied after cleansing face is prepared by hot-melting and blending the preparing raw materials in percentage by weight in a sterile environment and uniformly mixing. The conditioning water provided by the invention, when being used for massaging skin, not only can shrink pores, promote metabolism and keep skin bright and transparent, but also can assist the skin in functions of resisting inflammation, resisting oxidation, resisting bacteria, resisting allergy and the like.

Owner:SHENZHEN LINGZHONGLI TECH CO LTD

Biocidal compositions and their use in the control of microorganisms in aqueous and water containing systems

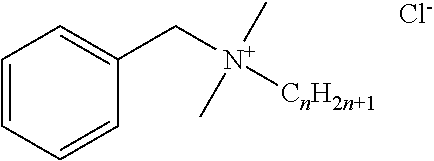

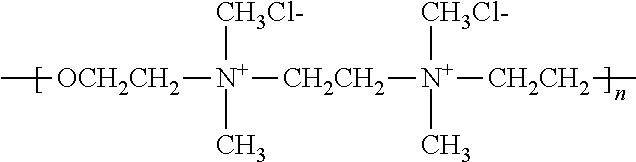

InactiveUS20150045223A1BiocideWaste water treatment from bathing facilitiesAmmonium compoundsMethylisothiazolinone

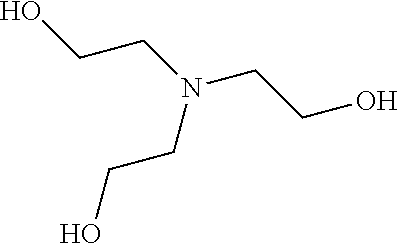

The invention provides a biocidal composition for controlling the growth of microorganisms in swimming pools and other aqueous systems. The composition includes: an antimicrobial substance for controlling microbial growth; an ionene polymer; and a synergist. The antimicrobial substance may be selected from the group consisting of: quaternary ammonium compounds such as cetylpyridinium chloride and benzalkonium chloride; isothiazolinone-derived compounds such as methylisothiazolinone; methylene bisthiocyanate; dibromonitrilopropionamide; and 2-bromo-2-nitropropane-1, 3-diol. The ionene polymer is preferably:poly[oxyethylene(dimethyliminio)-ethylene(dimethyliminio)-ethylene)dichloride]. The synergist may be selected from the group consisting of triethanolamine, diethanolamine, ethanolamine, ethanol, and triethylamine. Preferably the synergist is triethanolamine.

Owner:SHAW GORDON

Anti-freckle cream and preparation method thereof

ActiveCN103566300ALow costSignificant effectAnthropod material medical ingredientsDermatological disorderVitamin CGLYCYRRHIZA EXTRACT

The invention discloses an anti-freckle cream prepared from the following raw materials: isohexadecane, olive fruit oil, stearyl alcohol, polydimethylsiloxane, glycerin stearate, cetearyl alcohol polyether-6, cetearyl alcohol polyether-25, propyl hydroxybenzoate, butanediol, 2-bromo-2-nitropropane-1, 3-diol, imidazolidinyl urea, deionized water, functional components of traditional Chinese medicines and vitamin C, wherein the functional components of traditional Chinese medicines include the following constituents: silkworm larva, olibanum, savia miltiorrhiza, panax pseudoginseng, liquorice, cortex fraxini, turmeric and sambucus williamsii hance. The functional components of the traditional Chinese medicines in the anti-freckle cream are screened by adopting the syndrome differentiation theory of the traditional Chinese medicine and combining many-year clinical experience according to a freckle forming principle. The anti-freckle cream disclosed by the invention is low in cost, remarkable in curative effect and capable of achieving the aims of regulating qi and blood, dredging channels, activating blood and dissolving stasis as well as nourishing qi and blood, so that freckles are fundamentally treated.

Owner:TIANJIN JIASHITANG SCI & TECH

A kind of synthetic method of new florfenicol

ActiveCN106349130BNo burdenReduce processing costsOrganic chemistryOrganic compound preparationBenzeneSynthesis methods

The invention provides a synthesis method of florfenicol (I). The method is characterized by comprising the step of asymmetric Henry reaction: carrying out asymmetric Henry reaction on p-methylsulfuryl benzaldehyde (II) and fluoronitroethane (III) in a catalytic liquid to generate (1R,2S)-3-fluoro-1-(4-(methylsulfuryl)phenyl)-2-nitropropane-1-ol (IV). The florfenicol synthesis process does not increase the burden to the environment, and can save the pollutant treatment cost. In the florfenicol synthesis process, the reaction step is simple, thereby greatly lowering the cost. In the florfenicol synthesis process, the used catalyst is accessible, and the yield is higher.

Owner:WEIFANG DAYOU BIOLOGICAL CHEM CO LTD

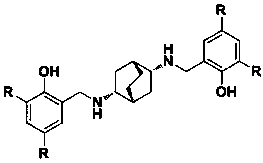

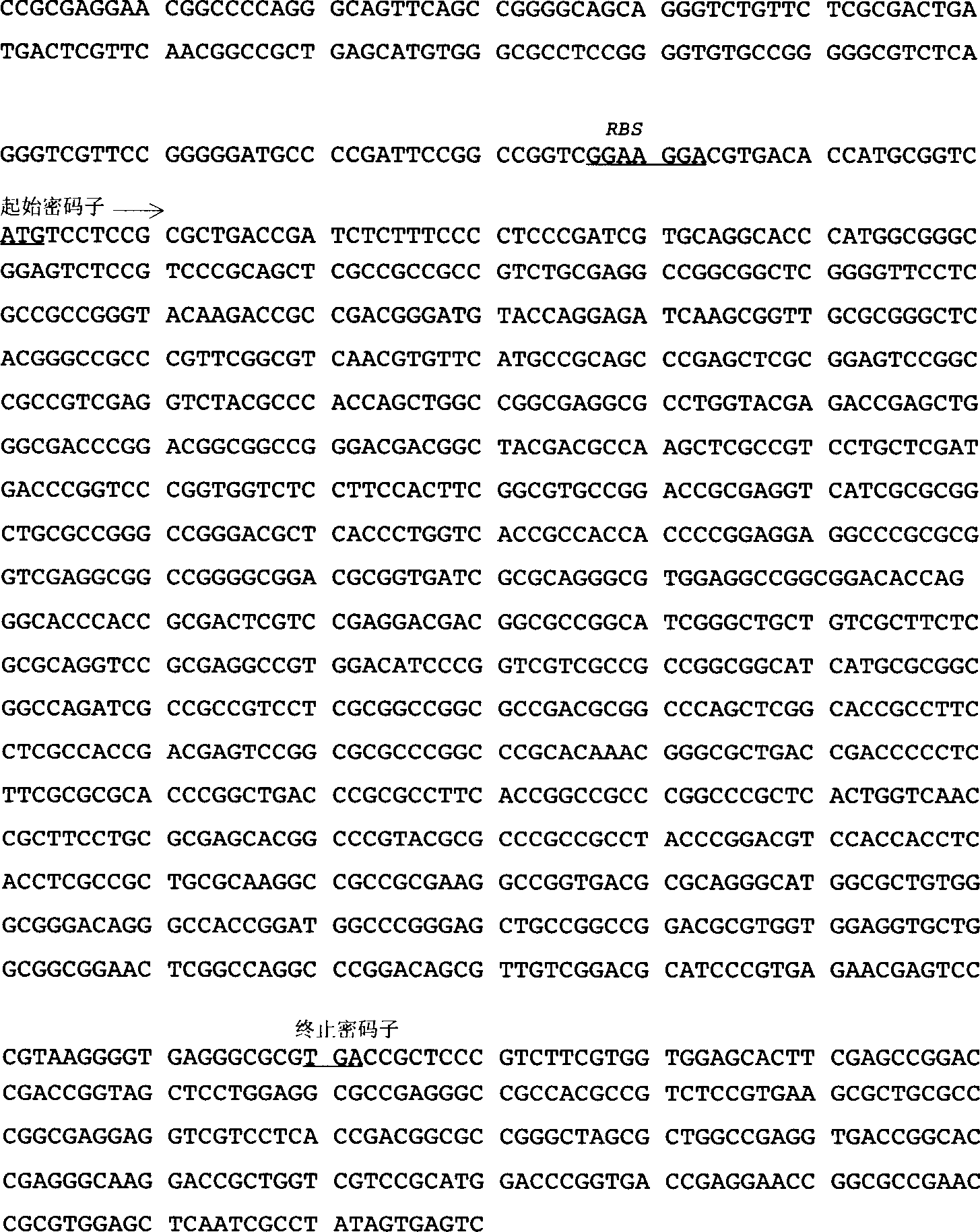

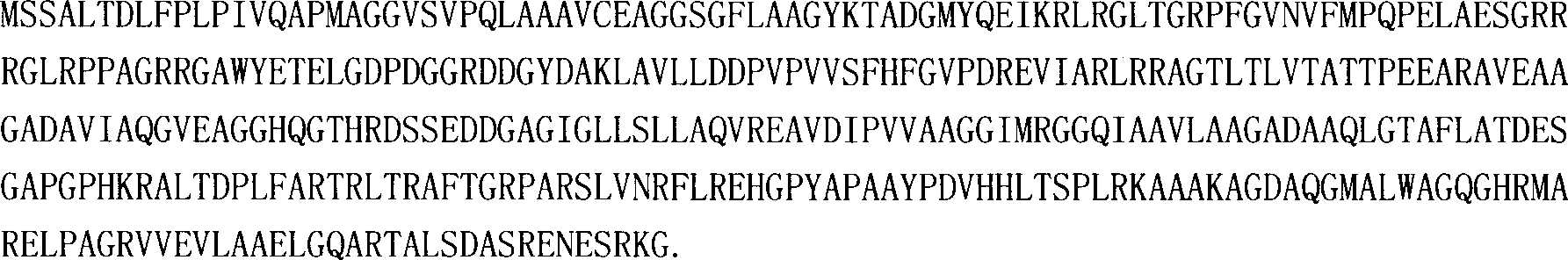

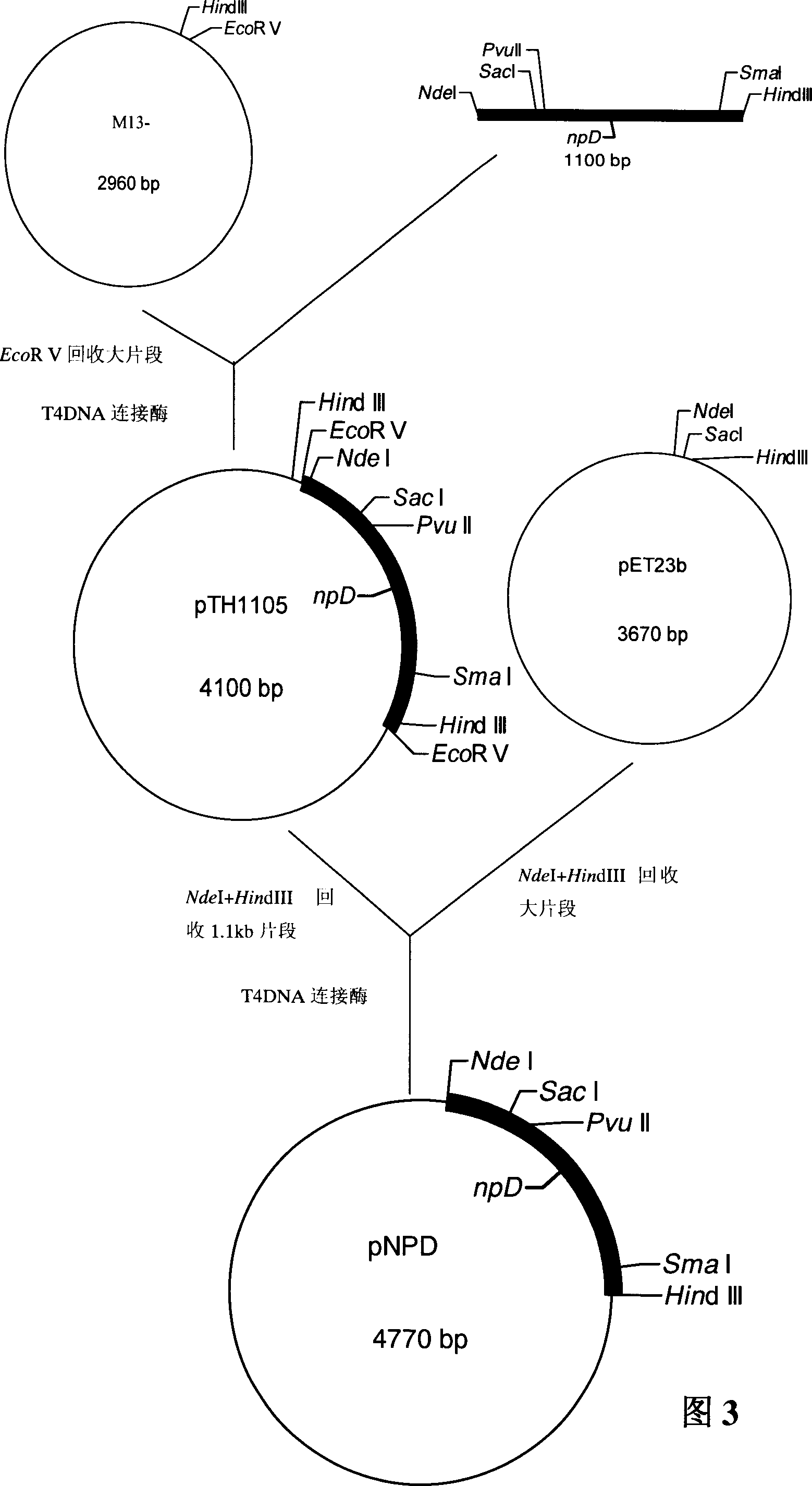

Streptomycete 2-nitropropane dioxyenase gene and its application

The present invention relates to the application of environmental microbe. Especially, by means of molecular technology, one new gene is cloned from Streptomyces ansochromogenes 7100 and the gene encodes one kind of 2-streptomycete dioxyenase. The encoded product has great value in biologically degrading industrial pollutant nitroalkane and in improving environment.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

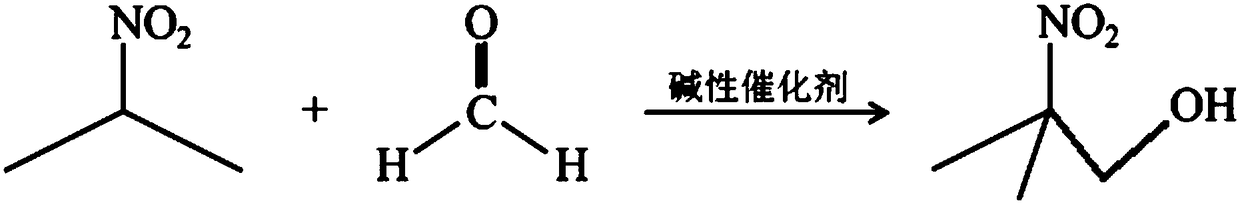

Green synthesis method for one-pot process preparation of AMP-95

InactiveCN108178731AReduce pollutionRaw materials are cheap and easy to getOrganic compound preparationAmino-hyroxy compound preparationSynthesis methods1-Propanol

The invention discloses a green synthesis method for the one-pot process preparation of AMP-95. The method comprises the following steps: S1, preparing 2-nitropropane from acetone, hydrogen peroxide and ammonia in an alcohol solution under the catalysis of a catalyst; S2, directly reacting a reaction solution obtained in step S1 with formaldehyde or paraformaldehyde under an alkaline condition without purifying in order to generate 2-nitro-2-methyl-1-propanol; and S3, directly hydrogenating the reaction product obtained in step S2 without purifying to obtain the product 2-amino-2-methy-1-propanol (AMP-95), and rectifying the product to make the purity reach 99.5% or more. The method has the advantages of cheap and easily available raw materials, simple reaction steps, small pollution to the environment, low cost, high yield, easiness in purification of the product, and suitableness for industrial production.

Owner:GUANGZHOU YINTIAN NEW MATERIAL CO LTD +1

Preparing method of low-carbon nitroparaffins

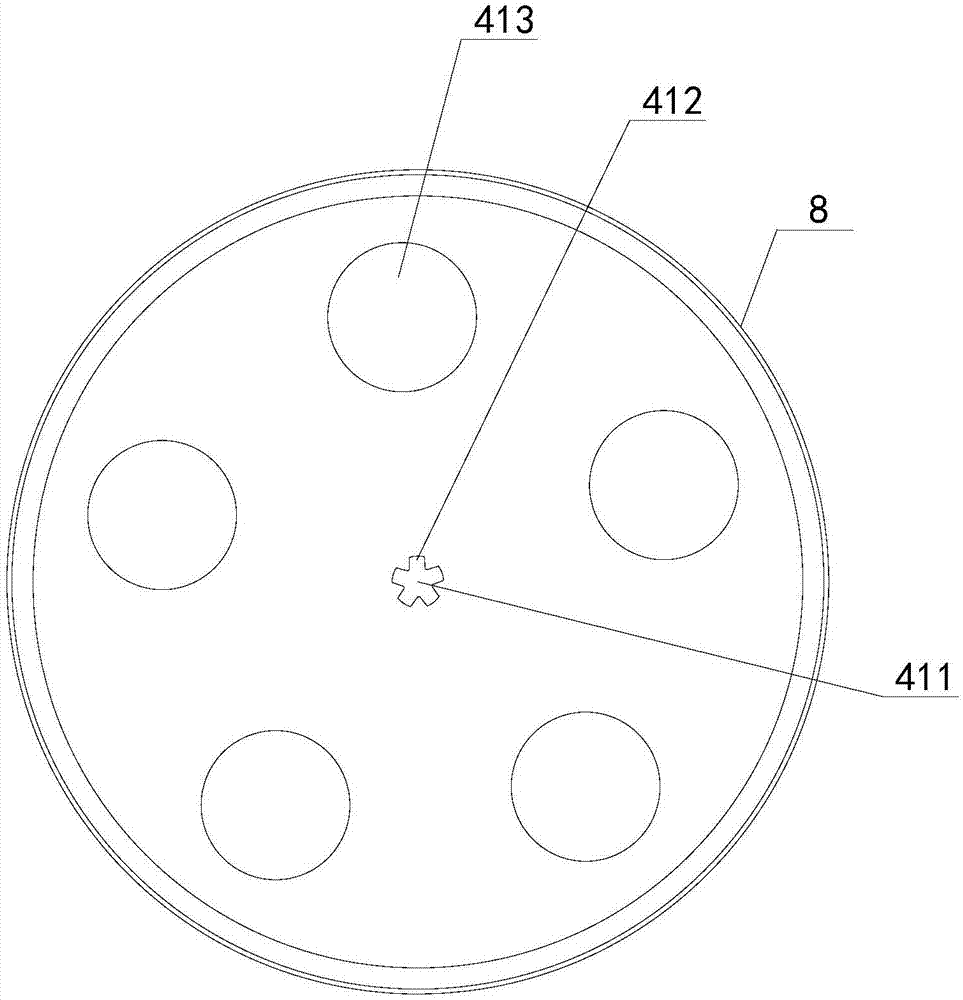

The invention provides a preparing method of low-carbon nitroparaffins. According to the method, a reaction is carried out in a multi-passage heat insulation reaction vessel by using propane as raw materials and using nitric acid as nitrating agents; four kinds of target products are obtained through controlling the reaction temperature to be 300 to 450 DEG C, the pressure to be 0 to 1.0 Mpa, the dwell time to be 0.5 to 2s and the mol ratio of the propane to the nitric acid to be (2-6):1; the selectivity of nitromethane is 4 to 7 percent; the selectivity of nitroethane is 9 to 13 percent; the selectivity of 1-nitropropane is 40 to 45 percent; and the selectivity of 2-nitropropane is 35 to 40 percent. The preparing method of the low-carbon nitroparaffins provided by the invention mainly has two major advantages that (1) four kinds of nitroparaffins with specific selectivity can be simultaneously obtained; and (2) the selectivity of nitration products is adjustable in a certain range.

Owner:嘉兴润博化工科技有限公司

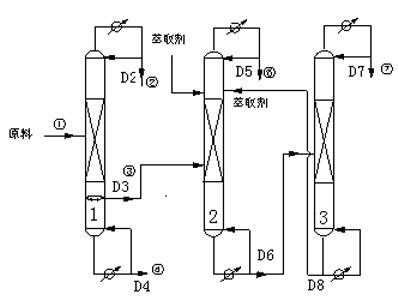

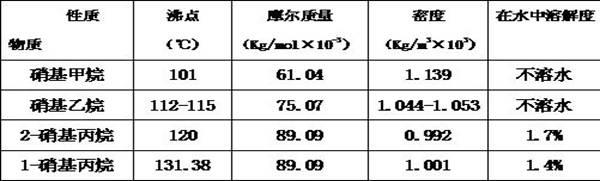

Method for orderly rectifying and separating nitromethane-nitroethane-nitropropane by continuous three towers

InactiveCN102229535AIncrease contentHigh yieldOrganic chemistryOrganic compound preparationTowerDistillation method

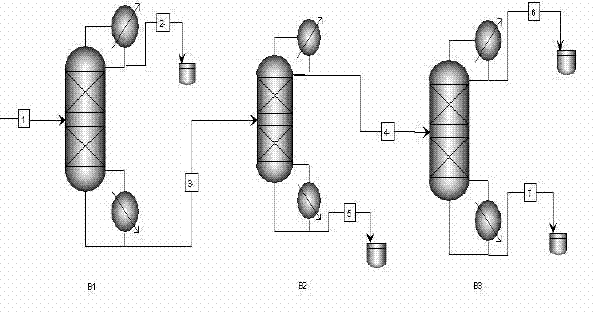

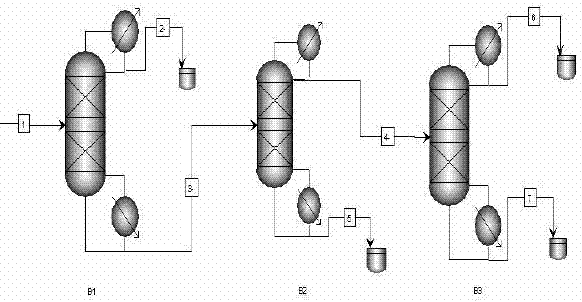

The invention relates to a method for orderly rectifying and separating nitromethane-nitroethane-nitropropane by continuous three towers, the raw material (an mixed solution of nitromethane, nitroethane,2-nitropropane and 1-nitropropane) is separated through a first continuous rectifying tower at first(B1), the content of the separated nitromethane on the top of the tower can reach over 99.5%, a distillate from the bottom is separated through the second continuous rectifying tower (B2), the content of the separated 1-nitropropane at the bottom of the tower can reach over 99.5%, the once through yields are respectively reach to 89.7% and 91.2%; a distillate from top of a second continuous rectifying tower (B2) is entered into a third continuous rectifying tower (B3) for separating nitroethane and 2-nitropropane, the content of nitroethane can reach above 82.0%, the content of 2-nitropropane can reach above 87.0%. Compared with the multi-times distillation method in the prior art, the separated product content and yield rate of the method provided in the invention are higher than that of the multi-times distillation method.

Owner:NANJING NORMAL UNIVERSITY

Skin care cosmetic product and preparation method

InactiveCN105919838AMoisturizing and powerfulImprove rough skinCosmetic preparationsToilet preparationsButyrospermum parkiiCoarse skin

The invention discloses a skin care cosmetic product which is composed of, by weight, 5-8% of glycerol, 3-5% of sodium pyrrolidonecarboxylate, 3-5% of polydimethylsiloxane, 5-8% of squalane, 3-5% of olive-pomace oil, 1-3% of cyclopentasiloxane, 0.5-1% of ceteareth-25, 1-3% of Butyrospermum parkii fruit butter, 1-2% of collagen, 0.15-0.3% of hyaluronic acid, 0.3-1% of bisabolol, 0.3-1% of allantoin, 0.2-1% of bishydroxymethyl imidazolidinyl urea, 0.05-0.1% of 2-bromo-2-nitropropane-1, 3-diol, 0.2-0.5% of essence and the balance of deionized water. The skin care cosmetic product has efficacy of being synergistic and moisturizing, relieving and restoring skin, quickly improving coarse skin and enabling the skin to be white and transparent again.

Owner:成都舒乐科技发展有限公司

Facial massage essence and preparation method thereof, and beautifying massage instrument

PendingCN107375018AKeep hydratedImprove skinCosmetic preparationsToilet preparationsFacial skinMedicine

The invention relates to facial massage essence and a preparation method thereof, and a beautifying massage instrument. The facial massage essence is prepared from the following raw materials by weight percent: 90-98% of deionized water, 1-3% of polyglycerol-10, 0.3-0.7% of collagen amino acids, 0.3-0.7% of rice amino acids, 0.3-0.7% of yeast amino acids, 0.3-0.7% of polyglutamic acid, 0.3-0.7% of diglycerol, 0.05-0.15% of glycerol caprylate, 0.01-0.1% of glyceryl laurate and 0.01-0.1% of 2-bromine-2-nitropropane-1,3-glycol, wherein the sum of the weight percents of the components is 100%. After the facial massage essence and the preparation method thereof as well as the beautifying massage instrument are adopted, the effects of moisturizing the facial skin and maintaining the skin to be moist can be achieved, a series of skin problems caused by long-term outdoor work or working by staring at a computer can be solved, and a function of relieving fatigue is reached.

Owner:屠岗峰 +3

Steam condensate corrosion inhibitor compositions and methods

ActiveUS7407623B2Scale removal and water softeningWater/sewage treatment by substance additionBrominePreservative

Lecithin and 2-bromo-2-nitropropane-1,3 diol (BNPD) are used to inhibit corrosion in boiler steam condensate systems. Aqueous steam condensate corrosion inhibiting compositions of these components are also disclosed. BNPD is also used as a preservative in lecithin containing and in other GRAS additive containing compositions.

Owner:BL TECH INC

Method of removing sulfides including hydrogen sulfide and mercaptan

InactiveUS7704380B2Adverse influenceLow costWaste water treatment from quariesGas treatmentAcetic acidThiol

In accordance with the present invention, a method of removing sulfide(s), which is safe, is effective over long periods at low cost, and exerts no adverse influences on the environment. The present invention relates to a method of removing sulfide(s), characterized in that a medium containing sulfide(s), including hydrogen sulfide and mercaptan(s), is allowed to come into contact with 2-bromo-2-nitropropane-1,3-diyl diacetate. Also, the present invention relates to the method, wherein the medium is a solid, liquid, or gas. In accordance with the present invention, sulfide(s), including hydrogen sulfide and mercaptan(s), can efficiently be treated so that they may be removed at low cost without the need for large-capacity equipment. In addition, the present invention can be safely practiced because there is no generation of byproducts that irritate the skin.

Owner:K I CHEM IND CO LTD

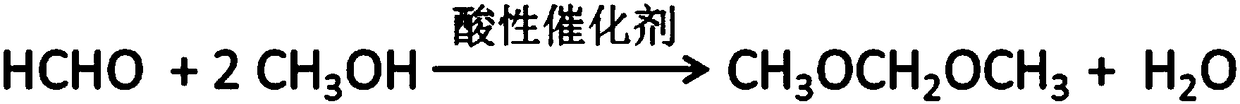

Preparation method of 2-nitro-2-methyl-1-propanol crystal

ActiveCN108976128AReduce typesLow costOrganic chemistryOrganic compound preparation1-PropanolMethyl group

The invention provides a preparation method of a 2-nitro-2-methyl-1-propanol crystal. According to the method, 2-nitro-2-methyl-1-propanol is prepared through a reaction between 2-nitropropane and paraformaldehyde, the residual formaldehyde is removed with an acidic solid catalyst, and the product is subjected to secondary purification with cyclohexane so as to obtain the 2-nitro-2-methyl-1-propanol crystal, wherein the purity is up to 99.8-99.99%, and the residual formaldehyde is 5-200 ppm; and the conversion rate of the reaction based on 2-nitropropane can be 98-99.7%, and the final yield after the secondary purification is 90-97%.

Owner:BEIJING RISUN TECH CO LTD

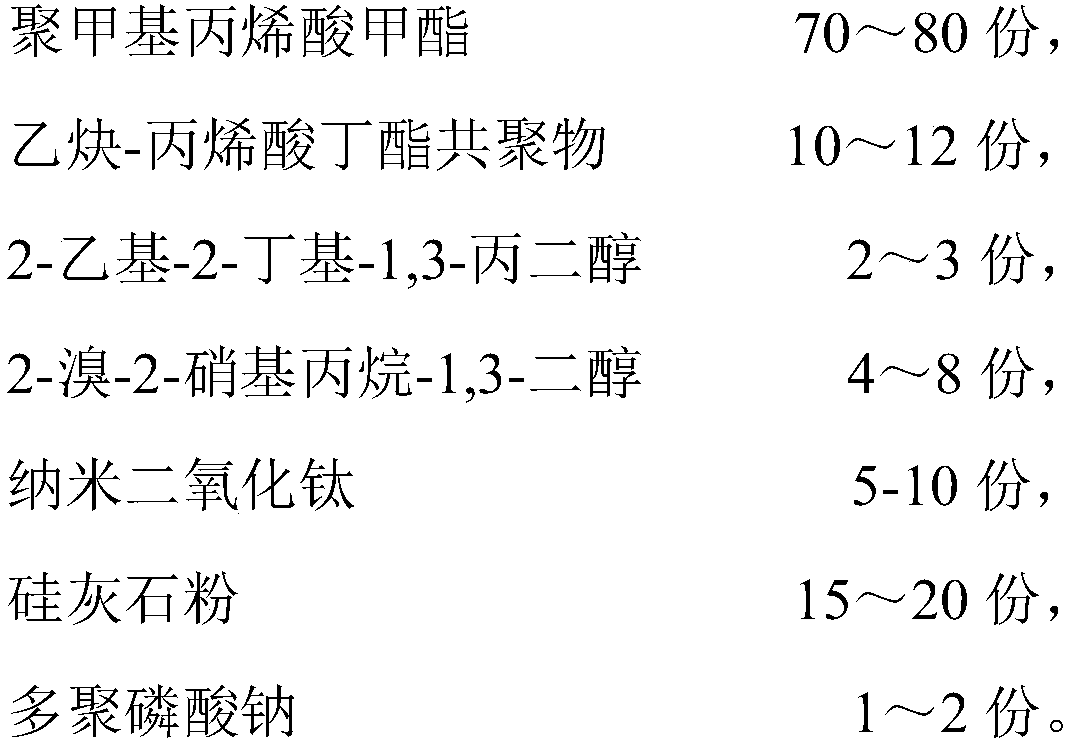

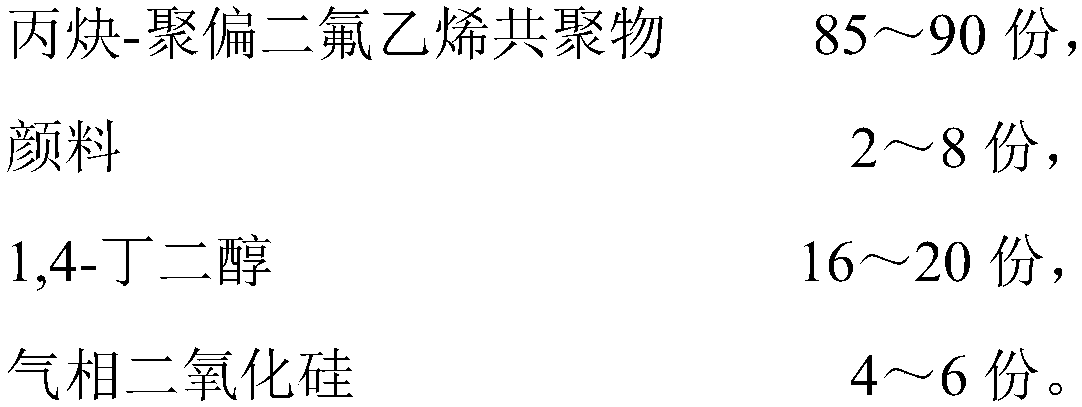

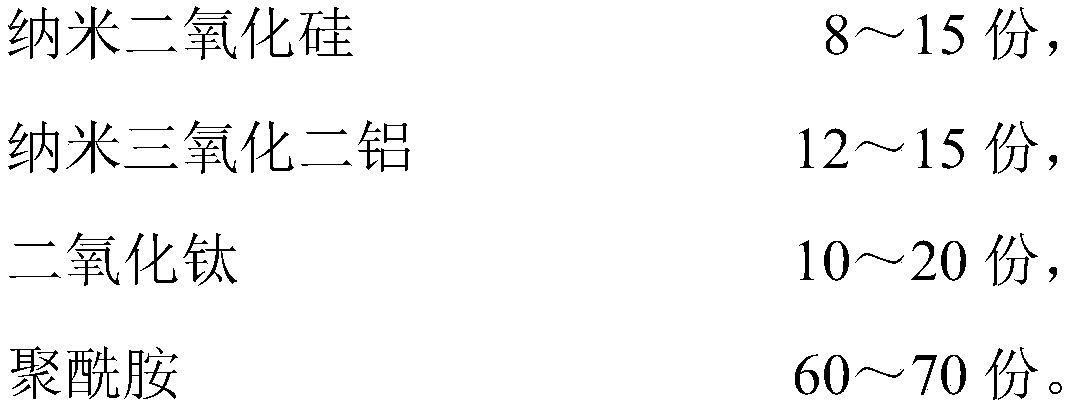

Anti-contamination invisible color-coated board and preparation method thereof

InactiveCN109382297AImprove stain resistanceInvisibility effect is goodCoatingsSpecial surfacesEpoxyMicrosphere

The invention belongs to the technical field of materials, and particularly relates to an anti-contamination invisible color-coated board and a preparation method thereof. The color-coated board comprises a top coating layer, bottom coating layer, first passivation layer, substrate, second passivation layer and back coating layer which are sequentially laminated; wherein, in the top coating layer,2-ethyl-2-butyl-1, 3-propanediol is matched with 2-bromine-2-nitropropane-1, 3-glycol to improve the roughness of the surface of the top coating layer, the hydrophobic performance of the top coatinglayer is improved and the stain resistance of the color-coated board is improved; nano titanium dioxide can catalyze and decompose pollutants such as organic matters and the like on the surface of thetop coating layer, and the addition of wollastonite powder can enhance the catalytic property of the nano titanium dioxide and further improve the stain resistance of the top coating layer. The top coating layer also comprises a hollow microsphere / carbon nano tube / epoxy resin and silicon carbide / carbon fiber composite material to achieve the invisible function of the color-coated board. In addition, the color-coated board has higher strength and weather resistance, the preparation method is simple, and the color-coated board is suitable for industrial production.

Owner:SUZHOU YANGTZE NEW MATERIALS CO LTD

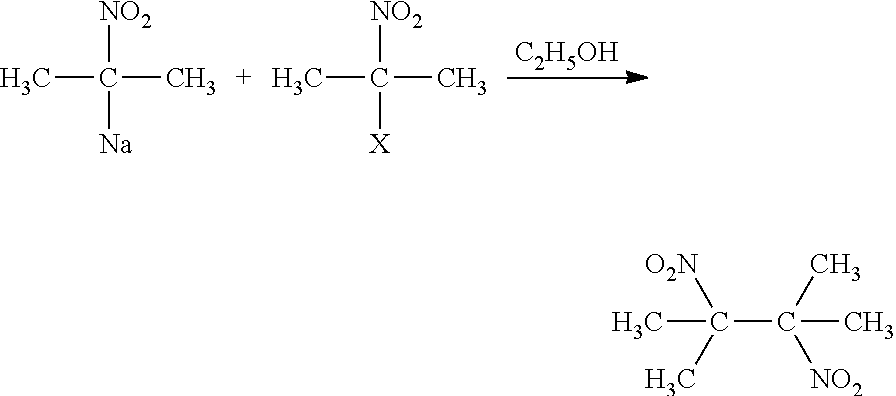

Method for preparing 2,3-dimethyl-2,3-dinitrobutane

InactiveUS8692036B2Process safetyEasily realizedOrganic compound preparationNitro compound preparationMolecular sieveTitanium

The present invention relates to a method for preparing 2,3-dimethyl-2,3-dinitrobutane (DMNB), which includes the following steps: (1) making titanium-silicate molecular sieve catalyst, acetone, hydrogen peroxide and ammonia contact and react at 65-80° C. to obtain a modified titanium-silicate molecular sieve catalyst; and (2-1) making acetone oxime and hydrogen peroxide contact and react in the presence of the modified titanium-silicate molecular sieve catalyst and water under the conditions of temperature of 60-90° C. and pH of 8-10, and separating DMNB from the reaction products thereof; or (2-2) making acetone, ammonia and hydrogen peroxide contact and react in the presence of the modified titanium-silicate molecular sieve catalyst and water under the conditions of temperature of 60-90° C. and pH of 8-10, and separating DMNB from the reaction products thereof. By the method provided by the present invention, DMNB can be prepared without having to use dangerous chemicals, such as 2-nitropropane, NaH and the like.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

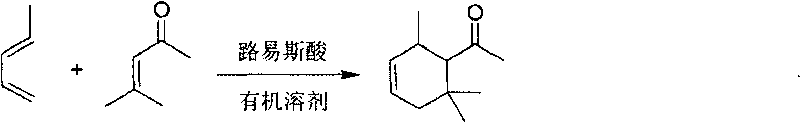

Method for preparing 1-(2,6,6-trimethylcyclohex 3-alkenyl) ethyl ketone

InactiveCN101225032BLow toxicityHigh yieldOrganic compound preparationCarbonyl compound preparationSolubilityKetone

The invention discloses a preparation method of organic compounds, in particular to 1- (2,6,6- trimethyl cyclohexyl - 3- alkenyl) ethyl ketone, which adopts 4- methyl amyl- 3- alkene - 2- alkone and 1,3- piperylenes as the raw material, with the anhydrous aluminum trichloride as the catalyst, and purifying and preparing through Diels-Alder reaction in the nitryl alkane solvent; wherein, the nitrylalkane solvent is one or several combination solvents among the nitroethane, 1- nitropropanes, and 2- nitropropanes, with a mass ratio of 3 to 5 times of 4- methyl amyl- 3- alkene -2- alkone. The preparation method of organic compounds has the advantages of using nitryl alkane as solvent, distinct enhancement of product efficiency, small solvent toxicity, good solubility, high recycling percentage, easy separation and purification of products, pure product fragrance, and other characteristics.

Owner:格林生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com