Method for separating nitroethane and 2-nitropropane by combined process of continuous side distillation and extractive distillation

A technology for nitroethane and nitropropane, which is applied in the field of continuous side-line rectification and extractive rectification integrated separation of nitroethane and 2-nitropropane, can solve the problem that the yield can only reach 53% and the operation process is complicated. , many middle distillates and other problems, to achieve the effect of reduced energy consumption, high separation efficiency and huge potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

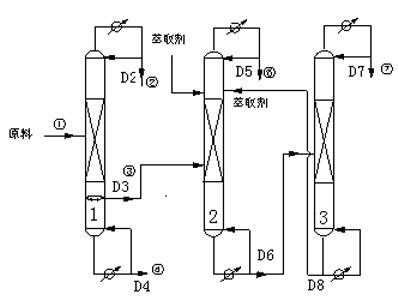

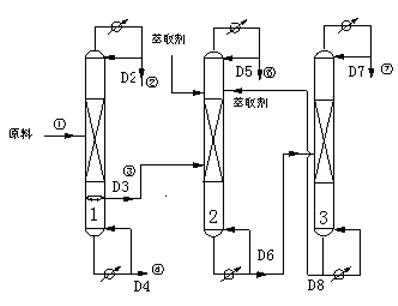

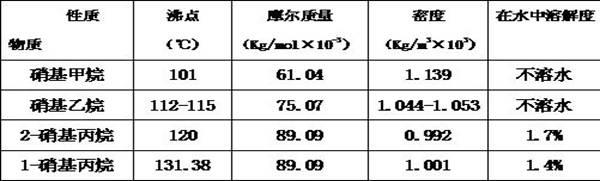

[0027] Continuous side rectification and extractive distillation integrated separation method for nitroethane and 2-nitropropane, refer to figure 1 Shown technology and parameter shown in table 2, the mass percent compositions of nitromethane, nitroethane, 2-nitropropane and 1-nitropropane in the mixed nitroalkane of raw material ① are respectively 13.46%, 82.35%, 4.16% and 0.03%, the flow rate is 10Kg / h.

[0028] The inner diameter of each tower is 57cm, and the φ3×3θ stainless steel packing is used. The equal plate height of the packing is HETP=27mm as measured by the standard system. Feedstock and individual fractions were analyzed quantitatively and qualitatively.

[0029] The separation method includes the following steps:

[0030] (1) Raw materials mixed with nitroalkanes ① put into the continuous side stream rectification column, the tower tank is heated by the resistance wire controlled by the pressure regulator, the feed rate is controlled at 10Kg / h, and the dischar...

Embodiment 2

[0038] Example 2 is basically the same as Example 1, but the mass ratio of the extraction agent in the (2) step to the raw material feed to the extractive distillation column is 1:0.8.

Embodiment 3

[0039] Example 3 is basically the same as Example 1, but the mass ratio of the extraction agent in the (2) step to the raw material feed to the extractive distillation column is 1:1.2.

[0040] The method of the present invention is not limited by the above-mentioned specific devices and process parameters. Those skilled in the art can adjust the relevant parameters or implement corresponding changes or transformations within the scope of the present invention according to the process conditions; Scale up accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com