Anti-contamination invisible color-coated board and preparation method thereof

A color-coated board and anti-contamination technology, which is applied in the field of materials, can solve the problems of being easily stained by dust and unable to achieve camouflage effects, etc., and achieves simple process, excellent anti-contamination performance and invisible effect, and enhanced adhesion. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

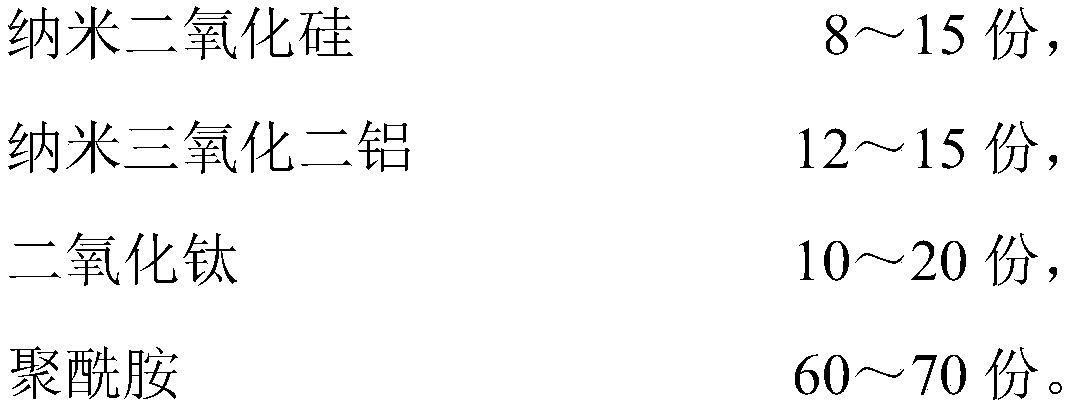

[0042] The invention provides an anti-contamination invisible color-coated plate, which comprises a top coat layer, an undercoat layer, a first passivation layer, a substrate, a second passivation layer and a back coat layer which are sequentially stacked.

[0043] Wherein, the substrate is a cold-rolled steel plate with a thickness of 0.3mm.

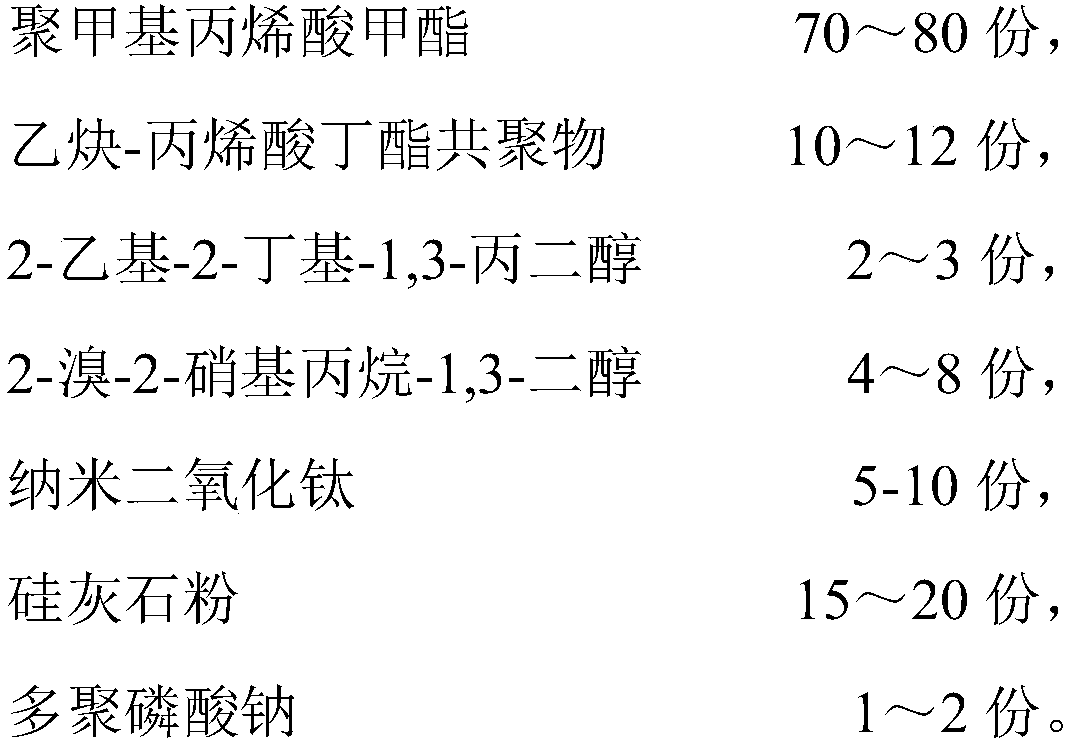

[0044] The first passivation layer and the second passivation layer are arranged on the two surfaces of the substrate respectively, and the two materials are the same, including 11.5 parts by weight of nano-silicon dioxide, 13.5 parts by weight of nano-alumina, 15 parts by weight of titanium dioxide, polyamide 65 parts by weight. The first passivation layer and the second passivation layer are cross-linked and passivated by titanium dioxide and polyurethane, and by adding synergistic slow-release factors nano-silicon dioxide and nano-alumina, the first passivation layer and the second passivation layer are effectively improved. Corrosi...

Embodiment 2

[0079] The invention provides an anti-contamination invisible color-coated plate, which comprises a top coat layer, an undercoat layer, a first passivation layer, a substrate, a second passivation layer and a back coat layer which are sequentially stacked.

[0080] Wherein, the substrate is a cold-rolled steel plate with a thickness of 0.5mm.

[0081] The first passivation layer and the second passivation layer are arranged on the two surfaces of the substrate respectively, and the two materials are the same, including 15 parts by weight of nano-silicon dioxide, 12 parts by weight of nano-alumina, 20 parts by weight of titanium dioxide, polyamide 60 parts by weight.

[0082] The thickness of the first passivation layer is 20 μm; the thickness of the second passivation layer is 30 μm.

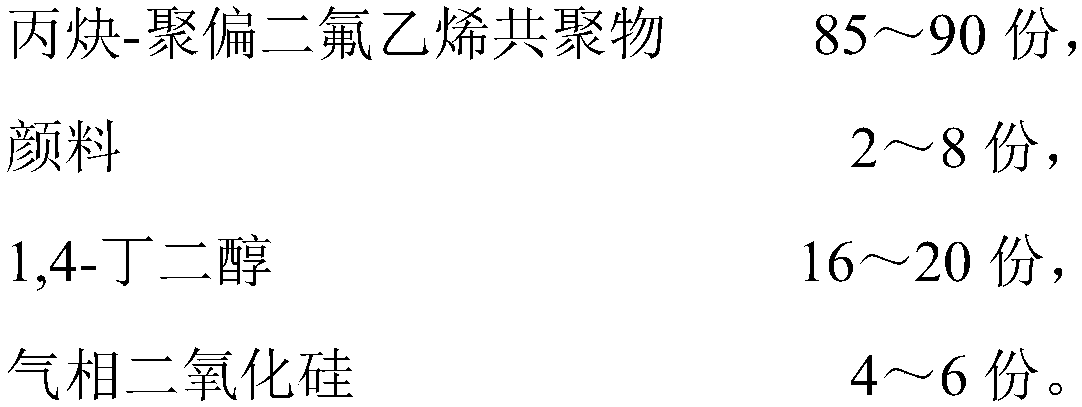

[0083] The primer layer is arranged on the first passivation layer, including 90 parts by weight of propyne-polyvinylidene fluoride copolymer, 8 parts by weight of pigment, 16 parts by weight o...

Embodiment 3

[0111] The invention provides an anti-contamination invisible color-coated plate, which comprises a top coat layer, an undercoat layer, a first passivation layer, a substrate, a second passivation layer and a back coat layer which are sequentially stacked.

[0112] Wherein, the substrate is a cold-rolled steel plate with a thickness of 0.4 mm.

[0113] The first passivation layer and the second passivation layer are arranged on the two surfaces of the substrate respectively, and the two materials are the same, including 8 parts by weight of nano-silicon dioxide, 15 parts by weight of nano-alumina, 10 parts by weight of titanium dioxide, polyamide 70 parts by weight.

[0114] The thickness of the first passivation layer is 25 μm; the thickness of the second passivation layer is 25 μm.

[0115] The primer layer is arranged on the first passivation layer, including 85 parts by weight of propyne-polyvinylidene fluoride copolymer, 2 parts by weight of pigment, 20 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com