A kind of synthetic method of new florfenicol

A technology of florfenicol and synthetic method, which is applied in the field of florfenicol synthesis, can solve the problems of low total yield, long route, high waste water treatment cost, etc., and achieve the goal of saving treatment cost, simple reaction steps and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

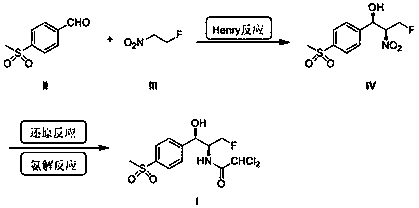

[0030] Example 1 Preparation of (1R,2S)-3-fluoro-1-(4-(thymphenyl)benzene)-2-nitropropane-1-ol (IV)

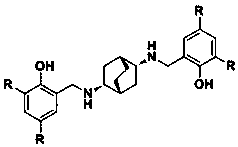

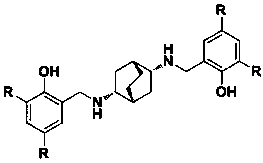

[0031] Step 1 Preparation of catalytic solution: 3Å molecular sieve, tetrahydro-salen ligand (Ia) (82 mg, 0.2 mmol), (CuOTf) 2 .C 6 h 5 CH 3 (10 mg, 0.02 mmol) was added into dichloromethane (8 mL) to prepare a catalytic solution; the addition amount of the tetrahydro-salen ligand (Ia) was 10 mol of the addition amount of thiamphenicol benzaldehyde (II) %; the CuOTf) 2 .C 6 h 5 CH 3 The amount of added accounted for 1 mol% of the added amount of thiamphenicol benzaldehyde (II).

[0032] Step 2 Asymmetric Henry reaction: add fluoronitroethane (III) (2.1 g, 0.022 mol) to the prepared catalytic solution, stir at room temperature for 10 minutes, add p-thiamphenicol benzaldehyde (II) (3.7 g, 0.02 mol), heated to 30°C and stirred for 24 hours to carry out catalytic reaction.

[0033] Step 3 Collection: The material after the catalytic reaction was distilled under reduced p...

Embodiment 2

[0035] Example 2 Preparation of (1R,2S)-3-fluoro-1-(4-(thymphenyl)benzene)-2-nitropropan-1-ol (IV)

[0036] Step 1 Preparation of catalytic solution: 3Å molecular sieve, tetrahydro-salen ligand (Ib) (93 mg, 0.2 mmol), (CuOTf) 2 .C 6 h 5 CH 3 (10 mg, 0.02 mmol) were sequentially added into tetrahydrofuran (8 mL) to obtain a catalytic solution; the addition amount of the tetrahydro-salen ligand (Ia) was 10 mol% of the addition amount of thiamphenicol benzaldehyde (II) ; the CuOTf) 2 .C 6 h 5 CH 3 The added amount accounted for 1 mol% of the added amount of thiamphenicol benzaldehyde (II)

[0037] Step 2 Asymmetric Henry reaction: Add fluoronitroethane III (2.1 g, 0.022 mol) to the catalytic solution, stir at room temperature for 10 minutes, add p-thiamphenicol benzaldehyde II (3.7 g, 0.02 mol), heat Stir the reaction at 25 degrees for 24 hours, and the reaction is complete.

[0038] Step 3 Collection: Distill the mixed material after the catalytic reaction under reduce...

Embodiment 3

[0040] Example 3 Preparation of (1R,2S)-3-fluoro-1-(4-(thymphenyl)benzene)-2-nitropropan-1-ol (IV)

[0041] Step 1 Preparation of catalytic solution: 3Å molecular sieve, tetrahydro-salen ligand (Ic) (104 mg, 0.2 mmol), (CuOTf) 2 .C 6 h 5 CH 3 (10 mg, 0.02 mmol) were sequentially added to toluene (8 mL) to prepare a catalytic solution; the addition amount of the tetrahydro-salen ligand (Ia) was 10 mol% of the addition amount of thiamphenicol benzaldehyde (II) ; the CuOTf) 2 .C 6 h 5 CH 3 The amount of added accounted for 1 mol% of the added amount of thiamphenicol benzaldehyde (II).

[0042]Step 2 asymmetric Henry reaction: Add fluoronitroethane III (2.1 g, 0.022 mol) to the catalytic solution, stir at room temperature for 10 minutes, add p-thiamphenicol benzaldehyde II (3.7 g, 0.02 mol), heat Stir the reaction at 35°C for 24 hours, and the reaction is complete.

[0043] Step 3 Collection: The material after the catalytic reaction was distilled under reduced pressure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com