Method for purifying crude 2,5-furandicarboxylic acid by crystallization

A technology of furandicarboxylic acid and furanic acid, applied in directions such as organic chemistry, can solve problems such as environmental burden, and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

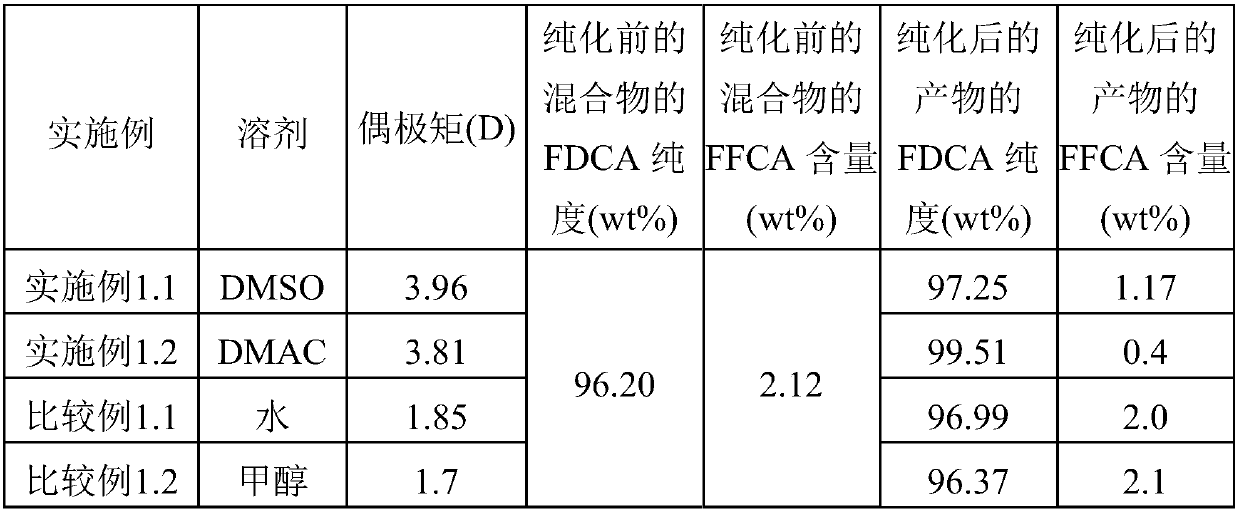

[0024] 75g of DMSO was mixed with 50g of FDCA crude product (FDCA purity 96.2wt%, FFCA content 2.12wt%) to form a mixture, and the mixture was heated to 100°C. After stirring the mixture at 100°C for 30 minutes, the mixture was cooled to room temperature at a rate of 1°C / min, and the mixture was filtered to obtain a filter cake. After washing the filter cake with DMSO, the filter cake was collected, and the filter cake was sent to an oven for drying to obtain a solid product. The purity of the product was analyzed by high performance liquid chromatography (HPLC), as shown in Table 1.

Embodiment 12

[0026]100 g of DMAC was mixed with 20 g of FDCA crude product (FDCA purity 96.2 wt%, FFCA content 2.12 wt%) to form a mixture, and the mixture was heated to 60°C. After stirring the mixture at 60°C for 30 minutes, the mixture was cooled to room temperature at a rate of 1°C / min, and the mixture was filtered to obtain a filter cake. After washing the filter cake with DMAC, the filter cake was collected, and the filter cake was sent to an oven for drying to obtain a solid product. The product purity was analyzed by HPLC, as shown in Table 1.

Embodiment 21

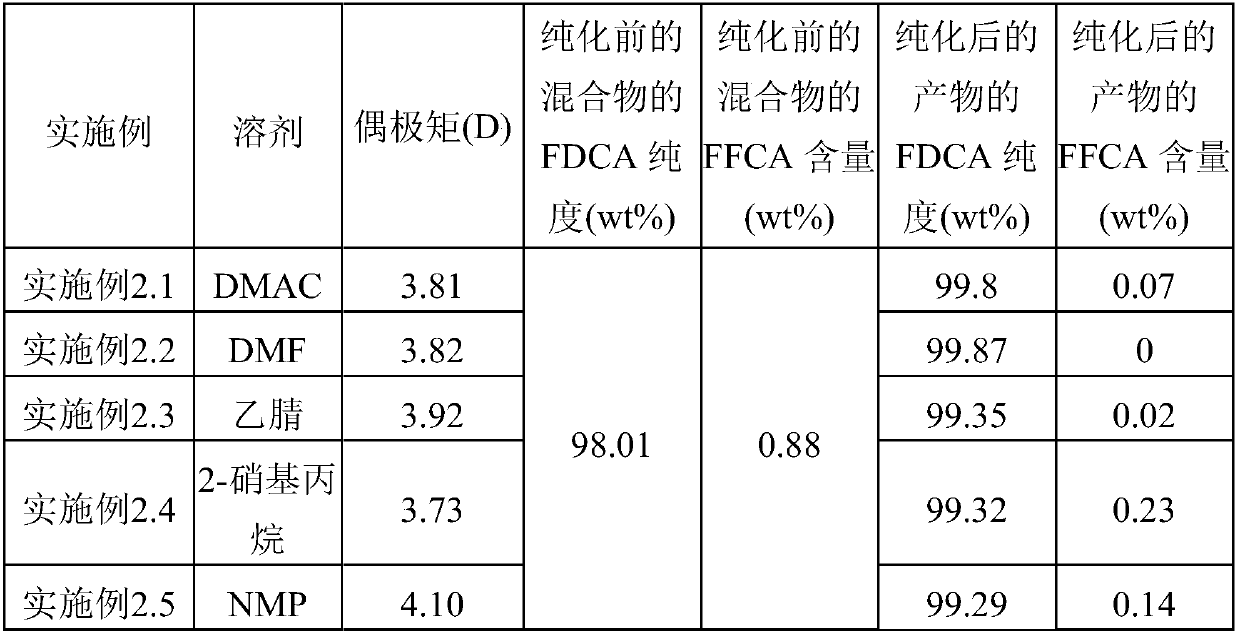

[0035] 100 g of DMAC was mixed with 20 g of FDCA crude product (FDCA purity 98.01 wt%, FFCA content 0.88 wt%) to form a mixture, and the mixture was heated to 60°C. After stirring the mixture at 60°C for 30 minutes, the mixture was cooled to room temperature at a rate of 1°C / min, and the mixture was filtered to obtain a filter cake. After washing the filter cake with DMAC, the filter cake was collected, and the filter cake was sent to an oven for drying to obtain a solid product. The product purity was analyzed by HPLC, as shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com