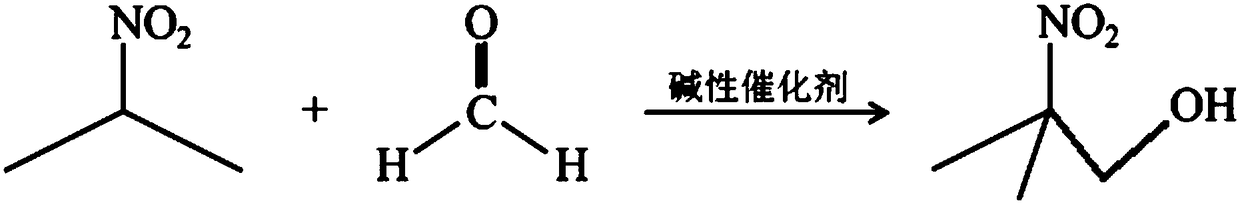

Preparation method of 2-nitro-2-methyl-1-propanol crystal

A technology of nitropropane and methyl, which is applied in the field of synthesis of 2-nitro-2-methyl-1-propanol, can solve problems such as undisclosed salt and formaldehyde treatment methods, affecting product quality, and formaldehyde residues. Achieve good industrial applicability, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 4000g of 2-nitropropane, 40g of methanol and 50g of 5mol / L NaOH aqueous solution into the reactor, stir and heat to 55℃, then add 95% formaldehyde to the reactor within 2 hours After adding 1516 g of paraformaldehyde, the temperature was raised to 65° C. and kept for 0.5 hour, so as to react to produce a reaction liquid containing 2-nitro-2-methyl-1-propanol. The reaction conversion rate based on 2-nitropropane was 99.7%, and the selectivity of 2-nitro-2-methyl-1-propanol was 99.7%.

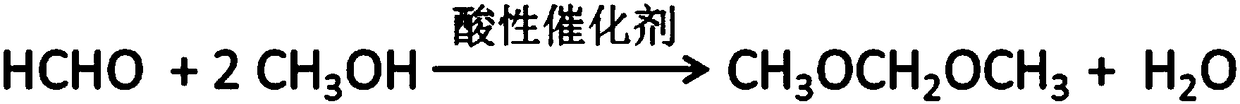

[0044] 5300g of methanol was added to the reaction solution to prepare a methanol solution, after which the alkali was removed by the acid purification resin, and then passed through a reactive distillation column equipped with a strong acid ion exchange resin (reaction conditions were the temperature at the bottom of the tower and the temperature at the top 50℃, reflux ratio is 6:1, pressure is normal pressure) to remove formaldehyde. The above-mentioned aldehyde-removing solution was t...

Embodiment 2

[0046] Add 4000g of 2-nitropropane, 10g of methanol and 50g of 5mol / L KOH aqueous solution into the reactor, stir and heat to 60℃, and then add 95% formaldehyde to the reactor within 2 hours 1488 g of paraformaldehyde, after the addition, the temperature was raised to 70° C. and kept for 0.5 hours, thereby reacting to produce a reaction liquid containing 2-nitro-2-methyl-1-propanol. The reaction conversion rate based on 2-nitropropane is 99.5%, and the selectivity of 2-nitro-2-methyl-1-propanol is 99.6%.

[0047] 5823g of methanol was added to the reaction solution to prepare a methanol solution, after which the alkali was removed by the acid purification resin, and then passed through a reactive distillation tower equipped with a strong acid ion exchange resin (reaction conditions were 69°C at the bottom of the tower and temperature at the top 52℃, reflux ratio is 5:1, pressure is normal pressure) to remove formaldehyde. The above-mentioned aldehyde-removing solution was transf...

Embodiment 3

[0049] Add 4000g of 2-nitropropane, 30g of methanol and 40g of triethylamine into the reactor, stir and heat to 55℃, and then add 1487g of paraformaldehyde with 95% formaldehyde content to the reactor within 1.5 hours After the addition, the temperature is raised to 63° C. and kept for 1 hour, so that the reaction produces a reaction liquid containing 2-nitro-2-methyl-1-propanol. The reaction conversion rate based on 2-nitropropane was 99.1%, and the selectivity of 2-nitro-2-methyl-1-propanol was 99.9%.

[0050] 6100g of methanol was added to the reaction solution to prepare a methanol solution, then the triethylamine was removed by the acid purifying resin, and then passed through a reactive distillation tower equipped with a strong acid ion exchange resin (reaction conditions were at the bottom of the tower at 68°C, the tower The top temperature is 54°C, the reflux ratio is 4:1, and the pressure is normal pressure) to remove formaldehyde. The above-mentioned aldehyde removal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com