Membrane-cleaning protective agent

A membrane cleaning and protective agent technology, applied in membrane technology, semi-permeable membrane separation, general water supply saving, etc., can solve problems such as reduction in desalination rate, achieve high water production, low environmental pollution, and reduce system operating pressure difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A membrane cleaning protective agent is composed of a membrane alkaline cleaning agent and a membrane cleaning bactericide.

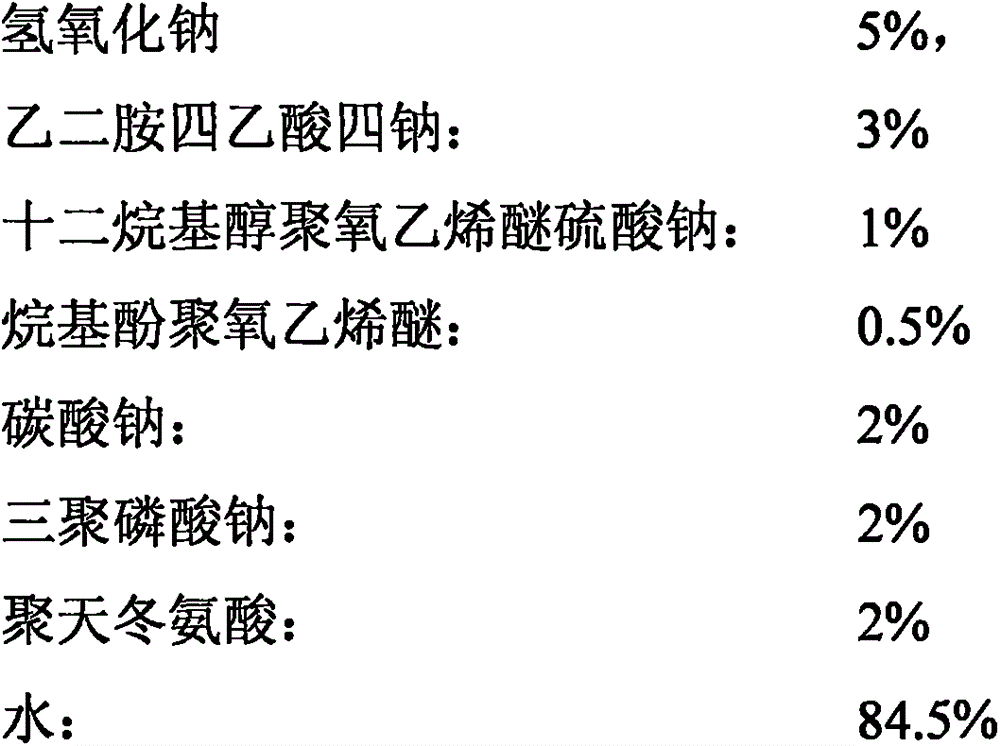

[0042] The formula of membrane alkaline cleaning agent is carried out first, and the formula is as follows:

[0043]

[0044] The above components are proportioned according to weight percentage.

[0045] The formulation of the membrane cleaning fungicide was then carried out, and the formulation was as follows:

[0046] Polyhexamethyleneguanidine: 10%

[0047] 2-Bromo-2-nitropropane-1,3-diol: 5%

[0048] Water: 85%

[0049] The above components are proportioned according to weight percentage.

[0050] Use the well-proportioned membrane alkaline cleaning agent and membrane cleaning and bactericide in a weight ratio of 10:1 as a foil cleaning and protecting agent.

Embodiment 2

[0052] A membrane cleaning protective agent is composed of a membrane alkaline cleaning agent and a membrane cleaning bactericide.

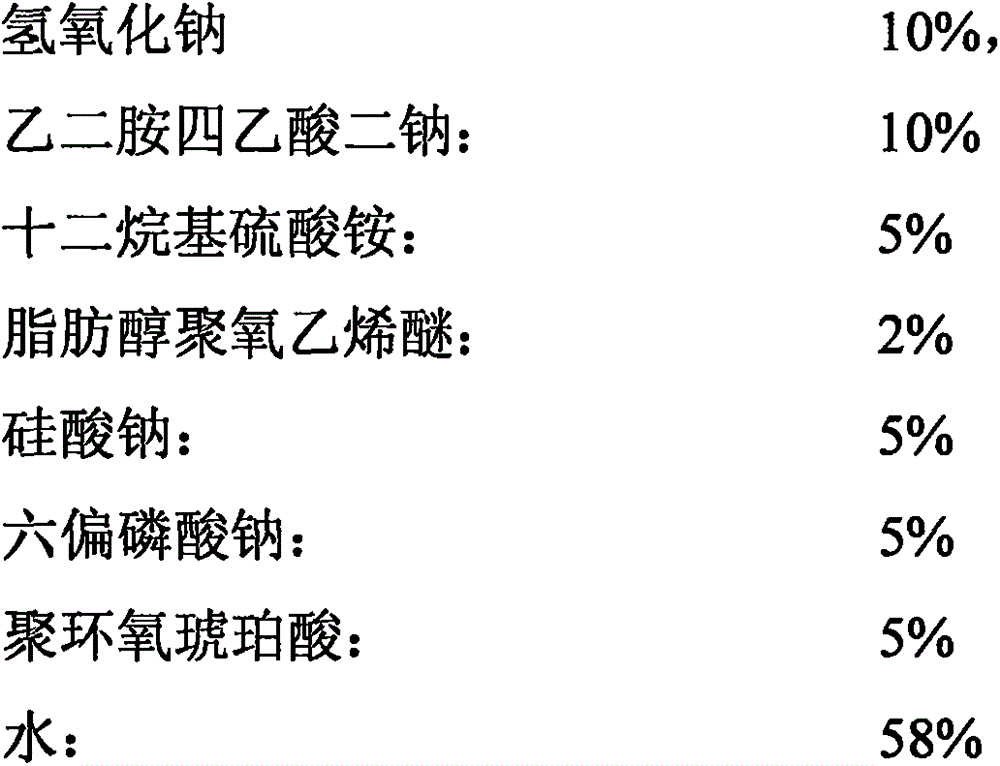

[0053] The formula of membrane alkaline cleaning agent is carried out first, and the formula is as follows:

[0054]

[0055] The above components are proportioned according to weight percentage.

[0056] The formulation of the membrane cleaning fungicide was then carried out, and the formulation was as follows:

[0057] Polyhexamethyleneguanidine: 15%

[0058] 2-Bromo-2-nitropropane-1,3-diol: 10%

[0059] Water: 75%

[0060] The above components are proportioned according to weight percentage.

[0061] Use the well-proportioned membrane alkaline cleaning agent and membrane cleaning and bactericide in a weight ratio of 10:1 as a foil cleaning and protecting agent.

Embodiment 3

[0063] A membrane cleaning protective agent is composed of a membrane alkaline cleaning agent and a membrane cleaning bactericide.

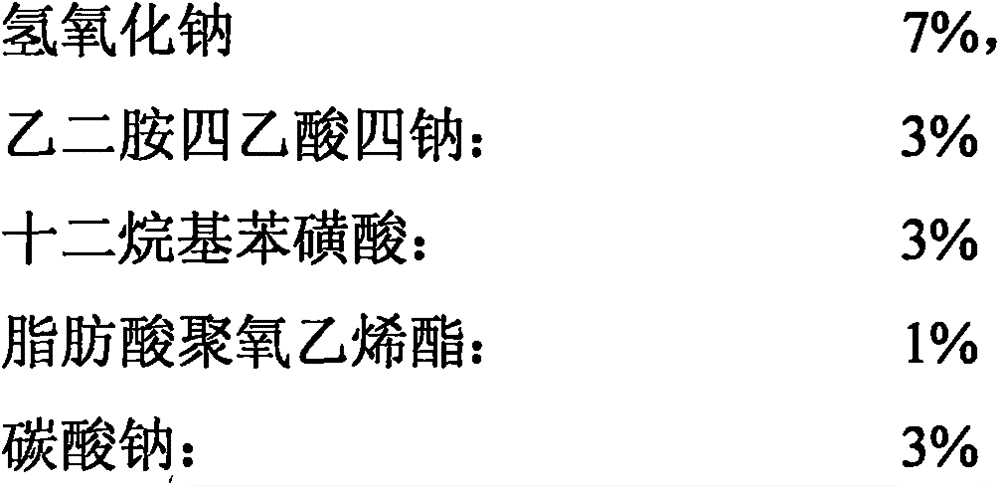

[0064] The formula of membrane alkaline cleaning agent is carried out first, and the formula is as follows:

[0065]

[0066]

[0067] The above components are proportioned according to weight percentage.

[0068] The formulation of the membrane cleaning fungicide was then carried out, and the formulation was as follows:

[0069] Polyhexamethyleneguanidine: 13%

[0070] 2-Bromo-2-nitropropane-1,3-diol: 7%

[0071] Water: 80%

[0072] The above components are proportioned according to weight percentage.

[0073] Use the well-proportioned membrane alkaline cleaning agent and membrane cleaning and bactericide in a weight ratio of 10:1 as a foil cleaning and protecting agent.

[0074] The cleaning effect of above-mentioned embodiment 1, embodiment 2, embodiment 3 and the single-component alkaline cleaning agent is compared with the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com