Visible light photocatalyst containing amorphous MgAl2O4 and preparation method thereof

An amorphous and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve rapid reaction, avoid system instability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Use urea and glycine as fuel, mix according to the molar ratio of magnesium nitrate: aluminum nitrate: urea: glycine = 1:2:1:5, heat on an electric furnace until it melts into a liquid, and then continue heating to completely burn the liquid to form a solid; The resulting solid is cooled to room temperature and ground to obtain a tan nanopowder, which is amorphous MgAl-containing 2 o 4 visible light catalyst.

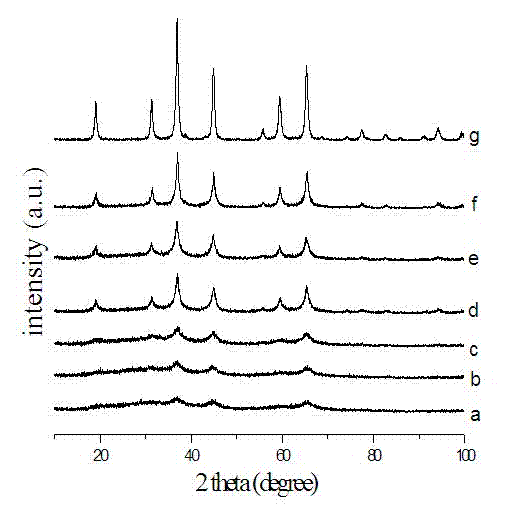

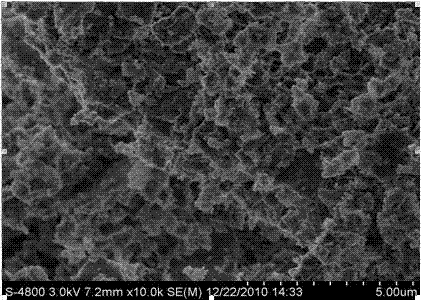

[0025] Carry out XRD, SEM and UV-Vis DRS test respectively to above-mentioned catalyst, test pattern is as follows respectively figure 1 Mid-spectrum line a, diagram 2-1 with Figure 4 The middle spectrum line a shows. from figure 1 It was calculated that the above catalyst contained crystalline MgAl 2 o 4 and amorphous MgAl 2 o 4 The weight percentages are 15.0% and 85.0%, respectively. from diagram 2-1 It can be seen that the catalyst prepared in this example is loose and porous, and its specific surface area (BET) is measured to be 33.8m 2 / g; ...

Embodiment 2

[0028] Use urea and DL-alanine as fuel, mix according to the molar ratio of magnesium nitrate: aluminum nitrate: urea: DL-alanine = 1:2:7:1, heat on an electric furnace until it melts into a liquid, and then continue heating The liquid is completely burned to form a solid; the resulting solid is cooled to room temperature and ground to obtain a tan nano-powder, which is amorphous MgAl-containing 2 o 4 visible light catalyst.

[0029] Carry out XRD and UV-Vis DRS test respectively to above-mentioned catalyst, test pattern is as follows respectively figure 1 Mid-spectral line b and Figure 4 In the spectral line b shown. From figure 1 It was calculated that the above catalyst contained crystalline MgAl 2 o 4 and amorphous MgAl 2 o 4 The weight percentages are 31.5% and 68.5%, respectively. Its BET is 29.7m 2 / g. From Figure 4 It can be seen from the figure that the catalyst prepared in this example has good absorption in the light region of 400-800nm.

[0030] Th...

Embodiment 3

[0032] Use urea and methyl carbamate as fuel, mix according to the molar ratio of magnesium nitrate: aluminum nitrate: urea: methyl carbamate = 1:2:5:4, heat on an electric furnace until it melts into a liquid, and then continue heating to make the liquid Complete combustion forms a solid; cool the resulting solid to room temperature and grind to obtain a tan nanopowder, which is amorphous MgAl-containing 2 o 4 visible light catalyst.

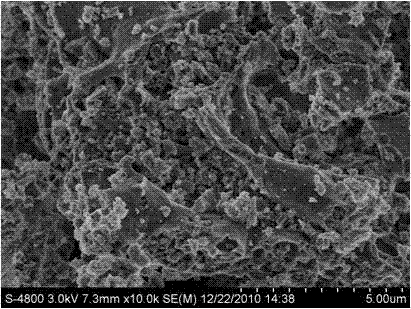

[0033] Carry out XRD, SEM, TEM and UV-Vis DRS test respectively to above-mentioned catalyst, test pattern is as follows respectively figure 1 Mid-spectral line c, Figure 2-2 , image 3 and Figure 4 In the spectral line c shown. From figure 1 It was calculated that the above catalyst contained crystalline MgAl 2 o 4 and amorphous MgAl 2 o 4 The weight percentages are 45.5% and 54.5%, respectively. From Figure 2-2 It can be seen that its porosity is reduced compared with the catalyst prepared in Example 1, and its BET is measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com