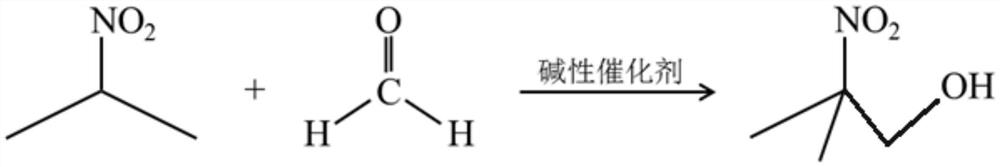

A kind of preparation method of 2-nitro-2-methyl-1-propanol crystal

A technology of nitropropane and methyl, which is applied in the field of synthesis of 2-nitro-2-methyl-1-propanol, can solve problems such as undisclosed salt and formaldehyde treatment methods, affecting product quality, and formaldehyde residues. Achieve the effect of good industrial applicability, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 4000g of 2-nitropropane, 40g of methanol and 50g of 5mol / L NaOH aqueous solution into the reaction kettle, stir and heat to 55°C, and then add formaldehyde content of 95% to the reaction kettle within 2 hours 1516g of paraformaldehyde was added, and after the addition, the temperature was raised to 65° C. and kept for 0.5 hours, thereby reacting to generate a reaction liquid containing 2-nitro-2-methyl-1-propanol. The reaction conversion based on 2-nitropropane was 99.7%, and the selectivity of 2-nitro-2-methyl-1-propanol was 99.7%.

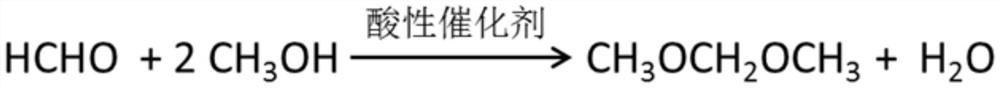

[0044] Add the methyl alcohol of 5300g in the reaction liquid and be made into methanol solution, then by acid purification resin alkali is removed, then pass through the reaction rectification tower (reaction condition is tower bottom temperature 70 ℃, tower top temperature) that strong acid ion exchange resin is housed 50°C, the reflux ratio is 6:1, and the pressure is normal pressure) to remove formaldehyde. The above-mentioned ald...

Embodiment 2

[0046] Add 4000g of 2-nitropropane, 10g of methanol and 50g of 5mol / L KOH aqueous solution into the reactor, stir and heat to 60°C, and then add formaldehyde content of 95% to the reactor within 2 hours. After the addition of 1488g of paraformaldehyde, the temperature was raised to 70°C and kept for 0.5 hours to react to generate a reaction solution containing 2-nitro-2-methyl-1-propanol. The reaction conversion based on 2-nitropropane was 99.5%, and the selectivity of 2-nitro-2-methyl-1-propanol was 99.6%.

[0047] Add the methyl alcohol of 5823g in the reaction liquid and be made into methanol solution, then by acid purification resin alkali is removed, then pass through the reaction rectification tower (reaction condition is tower bottom temperature 69 ℃, tower top temperature) that strong acid ion exchange resin is housed 52°C, the reflux ratio is 5:1, and the pressure is normal pressure) to remove formaldehyde. The above-mentioned aldehyde-removing solution was transferr...

Embodiment 3

[0049] Add 4000g of 2-nitropropane, 30g of methanol and 40g of triethylamine into the reactor, stir and heat to 55°C, then add 1487g of paraformaldehyde with a formaldehyde content of 95% to the reactor within 1.5 hours After the addition, the temperature was raised to 63° C. and kept for 1 hour, so that the reaction solution containing 2-nitro-2-methyl-1-propanol was generated. The reaction conversion based on 2-nitropropane was 99.1%, and the selectivity of 2-nitro-2-methyl-1-propanol was 99.9%.

[0050] Add 6100g of methanol to the reaction solution to form a methanol solution, then triethylamine is removed by an acidic purification resin, and then passed through a reactive distillation tower equipped with a strong acidic ion exchange resin (reaction conditions are 68 ° C at the bottom of the tower, and The top temperature is 54°C, the reflux ratio is 4:1, and the pressure is normal pressure) to remove formaldehyde. The above-mentioned aldehyde-removing solution is transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com