Organic synthesis intermediate acetone oxime synthesis method

A technology of organic synthesis and synthesis method, applied in the direction of organic chemistry, oxime preparation, etc., can solve the problems of complex process and low final yield, and achieve the effect of reducing intermediate links, shortening reaction time, and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

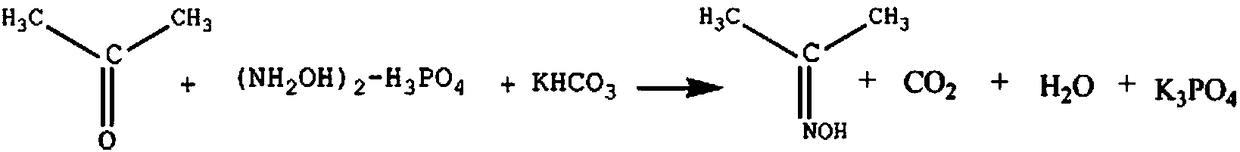

Method used

Image

Examples

example 1

[0011] Dissolve 0.5 mol of hydroxylamine phosphate in 20 L of potassium chloride solution with a mass fraction of 15%, slowly add 0.6 mol of acetone solution with a mass fraction of 30%, control the solution temperature at 35°C, let it stand for 90 minutes after adding, and lower the solution temperature to 31 ℃, add 0.9mol mass fraction of 20% potassium bicarbonate solution to adjust the pH of the solution to 8.5, control the solution temperature to 41 °C, separate the layers after cooling, separate the oil layer, and distill under reduced pressure at 50kPa to collect the fraction at 90 °C, the mass fraction Wash with 70% cyclohexane solution, wash with 90% isopropanol solution by mass fraction, dehydrate with anhydrous potassium carbonate dehydrating agent, cool and crystallize to obtain 33.215 g of finished acetone oxime with a yield of 91%.

example 2

[0013] Dissolve 0.5 mol of hydroxylamine phosphate in 20 L of potassium chloride solution with a mass fraction of 17%, slowly add 0.7 mol of acetone solution with a mass fraction of 32%, control the solution temperature at 37°C, let it stand for 100 minutes after adding, and lower the solution temperature to 32 ℃, add 0.9mol mass fraction of 22% potassium bicarbonate solution to adjust the pH value of the solution to 8.7, control the solution temperature to 43 ℃, separate the layers after cooling, separate the oil layer, distill under reduced pressure at 53kPa, collect the fraction at 93 ℃, the mass fraction Wash with 72% cyclohexane solution, wash with 93% isopropanol solution by mass fraction, dehydrate with anhydrous calcium sulfate dehydrating agent, cool and crystallize to obtain 33.945 g of finished acetone oxime with a yield of 93%.

example 3

[0015] Dissolve 0.5 mol of hydroxylamine phosphate in 20 L of potassium chloride solution with a mass fraction of 20%, slowly add 0.8 mol of acetone solution with a mass fraction of 35%, control the solution temperature at 39°C, let it stand for 110min after adding, and lower the solution temperature to 34 ℃, adding 0.9 mol mass fraction of 25% potassium bicarbonate solution to adjust the pH value of the solution to 9, controlling the solution temperature to 45 ℃, stratifying after cooling, separating the oil layer, distilling under reduced pressure at 55kPa, collecting the fraction at 95 ℃, mass fraction Wash with 75% cyclohexane solution, wash with 96% isopropanol solution by mass fraction, dehydrate with anhydrous potassium carbonate dehydrating agent, cool and crystallize to obtain 35.04 g of finished acetone oxime with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com