Preparation method of high-flow impact-resistant polypropylene material

A polypropylene material and high fluidity technology, applied in the field of polypropylene material preparation, can solve problems such as conversion difficulties, and achieve the effects of reducing production costs, good rigidity and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

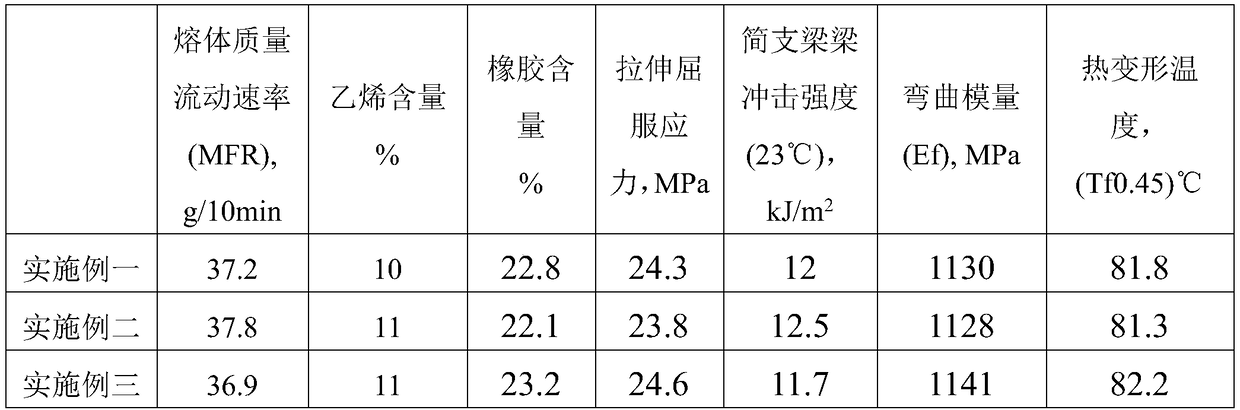

Examples

Embodiment 1

[0041] (1). Under the joint action of the main catalyst, co-catalyst and external electron donor, propylene is polymerized into polypropylene through the pre-polymerization reactor, and the ratio of antistatic agent to co-catalyst is controlled to 0.43.

[0042] (2). The pre-polymerization reaction product obtained by step (1) enters the first loop reactor with fresh propylene and hydrogen to continue the polymerization reaction. The hydrogen concentration of the first loop tube is controlled to be 1380ppm, the reaction temperature is 70°C, and the reaction pressure 3.4MPa, ring pipe density 545kg / m 3 .

[0043] (3) The polymerization reaction product obtained by step (2) enters the second loop reactor with fresh propylene and hydrogen to continue polymerization, and the hydrogen concentration of the second loop is controlled to be 1450ppm, the reaction temperature is 70°C, and the reaction pressure is 3.4MPa , ring pipe density 590kg / m 3 .

[0044] (4) The polymerization r...

Embodiment 2

[0047] (1). Under the joint action of the main catalyst, co-catalyst and external electron donor, propylene is polymerized into polypropylene through the pre-polymerization reactor, and the ratio of antistatic agent and co-catalyst is controlled to 0.45.

[0048] (2). The pre-polymerization reaction product obtained by step (1) enters the first loop reactor with fresh propylene and hydrogen to continue the polymerization reaction. The hydrogen concentration of the first loop is controlled to be 1500ppm, the reaction temperature is 70°C, and the reaction pressure 3.4MPa, ring pipe density 550kg / m 3 .

[0049] (3) The polymerization reaction product obtained by step (2) enters the second loop reactor with fresh propylene and hydrogen to continue polymerization, and the hydrogen concentration of the second loop is controlled to be 1500ppm, the reaction temperature is 70°C, and the reaction pressure is 3.4MPa , ring pipe density 585kg / m 3 .

[0050] (4) The polymerization react...

Embodiment 3

[0053] (1). Under the combined action of the main catalyst, co-catalyst and external electron donor, propylene is polymerized into polypropylene through the pre-polymerization reactor, and the ratio of antistatic agent to co-catalyst is controlled to 0.44.

[0054] (2). The pre-polymerization reaction product obtained by step (1) enters the first loop reactor with fresh propylene and hydrogen to continue the polymerization reaction. The hydrogen concentration of the first loop is controlled to be 1650ppm, the reaction temperature is 70°C, and the reaction pressure 3.4MPa, ring pipe density 550kg / m 3 .

[0055] (3) The polymerization reaction product obtained by step (2) enters the second loop reactor with fresh propylene and hydrogen to continue polymerization, the hydrogen concentration of the second loop is controlled to be 1550ppm, the reaction temperature is 70°C, and the reaction pressure is 3.4MPa , ring pipe density 595kg / m 3 .

[0056] (4) The polymerization reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com