High-temperature O2/CO2 corrosion inhibitor for coiled tubing and preparation method of agent B of high-temperature O2/CO2 corrosion inhibitor

A technology of CO2 and corrosion inhibitor, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., can solve problems affecting production operations, fractures, localized corrosion of coiled tubing, etc., and achieve the effect of ensuring safe operation and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

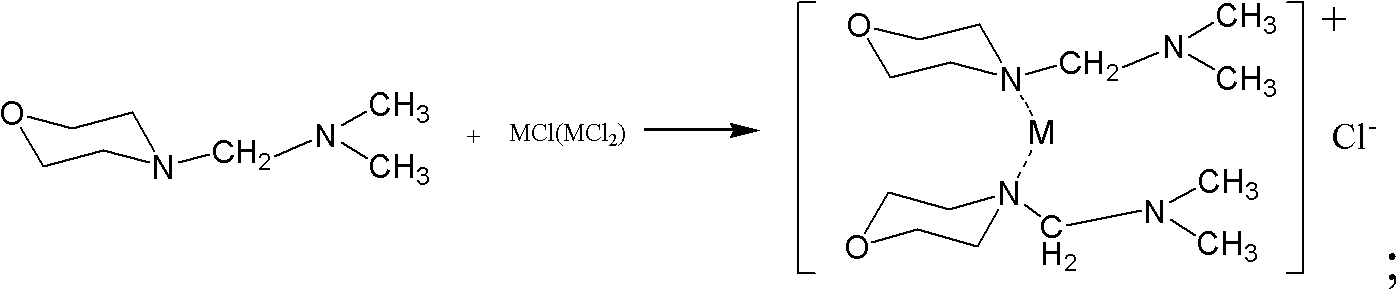

[0021] The invention provides a kind of high temperature anti-O 2 / CO 2 Corrosion inhibitor is used in combination with Agent A which mainly removes oxygen and Agent B which mainly resists carbon dioxide corrosion. L; the A agent is acetone oxime, D-ascorbic acid, sodium sulfite or ferric sulfite; the composition of the B agent is calculated by weight percentage: 20% to 30% of pyridine quaternary ammonium salt, 10% to Mannich base chelate 15%, surfactant 3-7%, solvent 48-67%.

[0022] Wherein, the surfactant in agent B is alkylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether or alkylphenol polyoxyethylene ether.

[0023] Wherein, the solvent in agent B is a mixture of dimethylformamide and methanol or a mixture of dimethylformamide and ethanol.

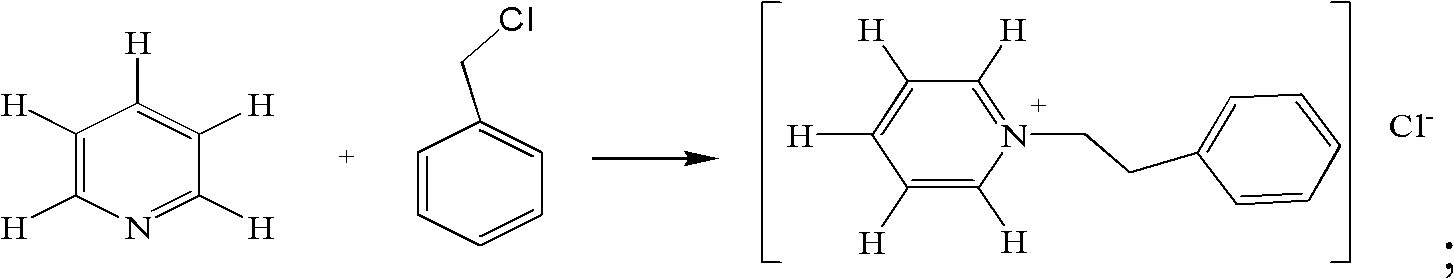

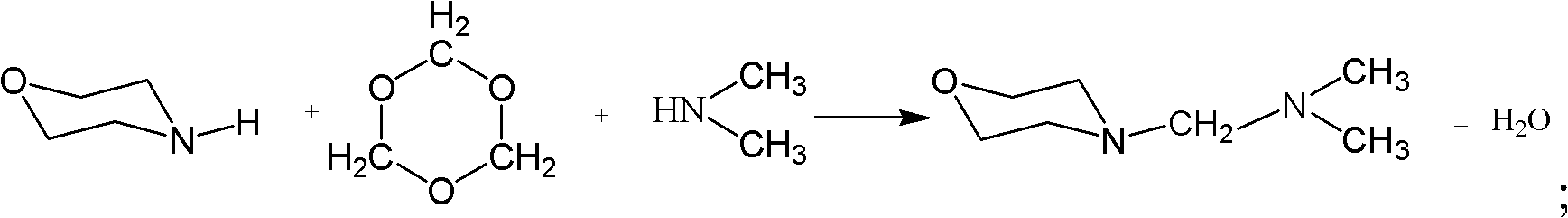

[0024] The coiled tubing provided by the invention is high temperature resistant to O 2 / CO 2 The preparation method of agent B in the corrosion inhibitor: the first step, pour pyridine and benzyl chloride into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com