Composite water treatment agent for thickened oil thermal recovery boiler and preparation method thereof

A water treatment agent and heavy oil thermal recovery technology, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc., can solve the problem of excessive iron content in steam and condensate, corrosion of thermal system, etc. problems, to achieve significant social benefits and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

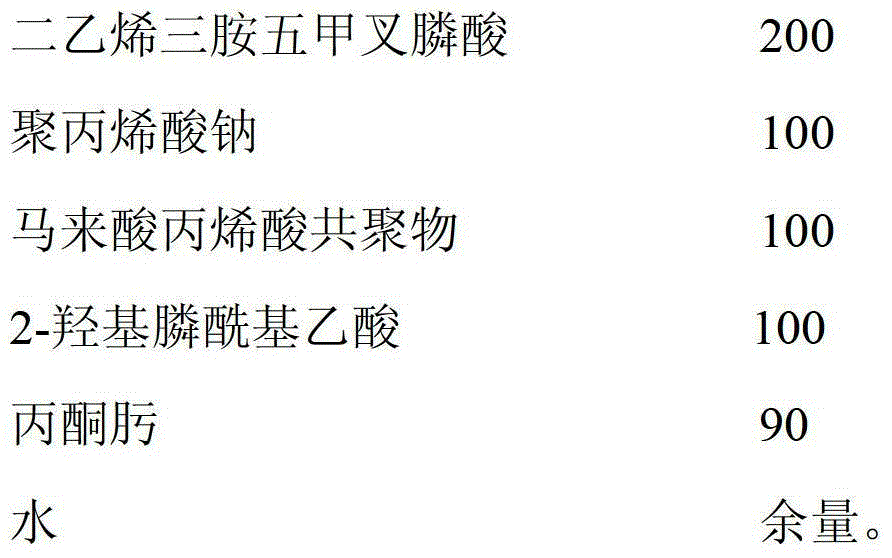

[0022] This embodiment provides a kind of composite water treatment agent for heavy oil thermal recovery boiler, with the total weight of the composite water treatment agent being 1000 parts by weight, it includes the following components:

[0023]

[0024] The composite water treatment agent for the heavy oil thermal recovery boiler is prepared according to the following steps:

[0025] Add water to the reaction kettle, and then add diethylenetriaminepentamethylenephosphonic acid, sodium polyacrylate, maleic acid acrylic acid copolymer, 2-hydroxyphosphonoacetic acid, acetone oxime while stirring. React for 30-40 minutes under normal pressure to obtain a composite water treatment agent for heavy oil thermal recovery boilers.

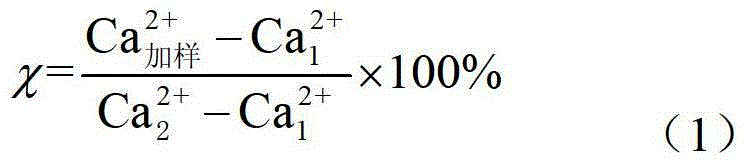

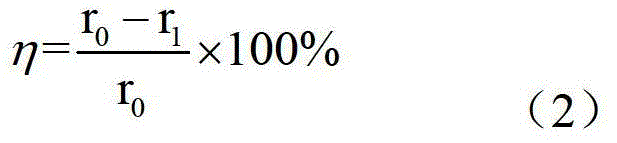

[0026] Technical effect test:

[0027] Add the composite water treatment agent for heavy oil thermal recovery boilers provided in this example to the boiler water supply of Qi 40. The dosage of the composite water treatment agent for heavy oil therma...

Embodiment 2

[0049] This embodiment provides a kind of composite water treatment agent for heavy oil thermal recovery boiler, with the total weight of the composite water treatment agent being 1000 parts by weight, it includes the following components:

[0050]

[0051] The composite water treatment agent for the heavy oil thermal recovery boiler is prepared according to the following steps:

[0052] Add water to the reaction kettle, and then add diethylenetriaminepentamethylenephosphonic acid, sodium polyacrylate, maleic acid acrylic acid copolymer, 2-hydroxyphosphonoacetic acid, acetone oxime while stirring. React for 30-40 minutes under normal pressure to obtain a composite water treatment agent for heavy oil thermal recovery boilers.

[0053] Technical effect test:

[0054] Add the composite water treatment agent for heavy oil thermal recovery boilers provided in this example to the boiler water supply in Xiaowa Oilfield. The dosage of the composite water treatment agent for heavy ...

Embodiment 3

[0059] This embodiment provides a kind of composite water treatment agent for heavy oil thermal recovery boiler, with the total weight of the composite water treatment agent being 1000 parts by weight, it includes the following components:

[0060]

[0061] The composite water treatment agent for the heavy oil thermal recovery boiler is prepared according to the following steps:

[0062] Add water to the reaction kettle, and then add diethylenetriaminepentamethylenephosphonic acid, sodium polyacrylate, maleic acid acrylic acid copolymer, 2-hydroxyphosphonoacetic acid, acetone oxime while stirring. React for 30-40 minutes under normal pressure to obtain a composite water treatment agent for heavy oil thermal recovery boilers.

[0063] Technical effect test:

[0064] Add the composite water treatment agent for heavy oil thermal recovery boilers provided in this example to the boiler water supply of Jin 45, and the dosage of the composite water treatment agent for heavy oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com