Patents

Literature

33results about How to "Meet the needs of on-site production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

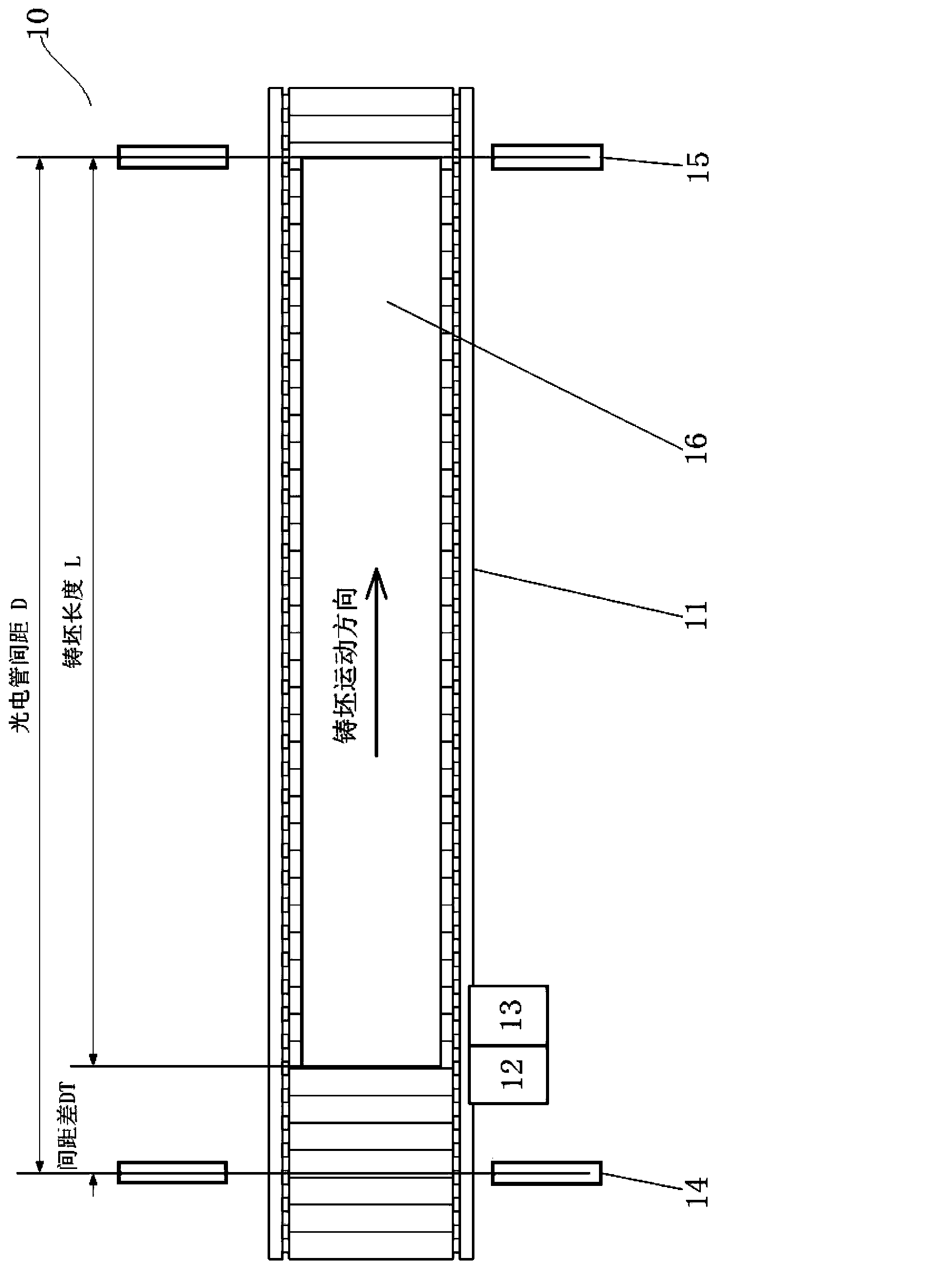

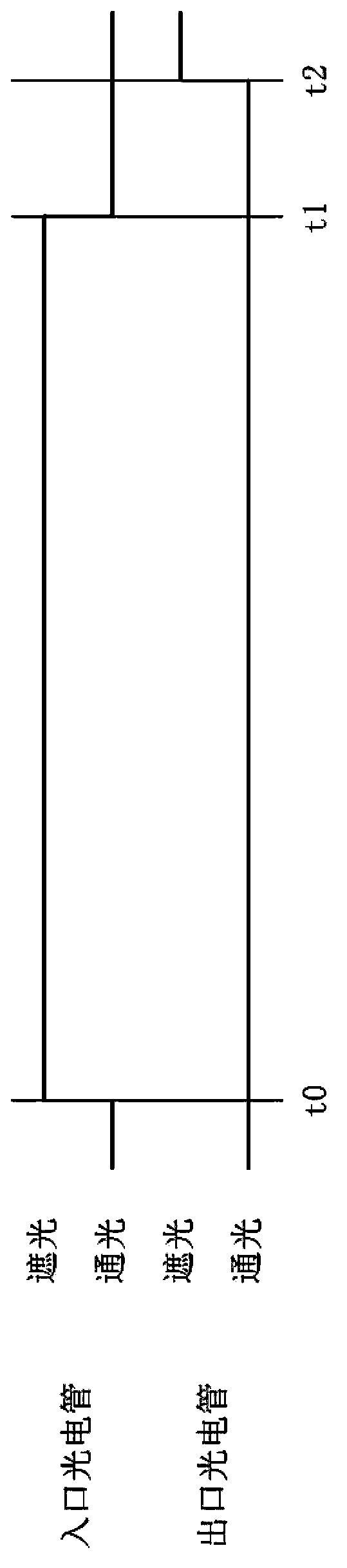

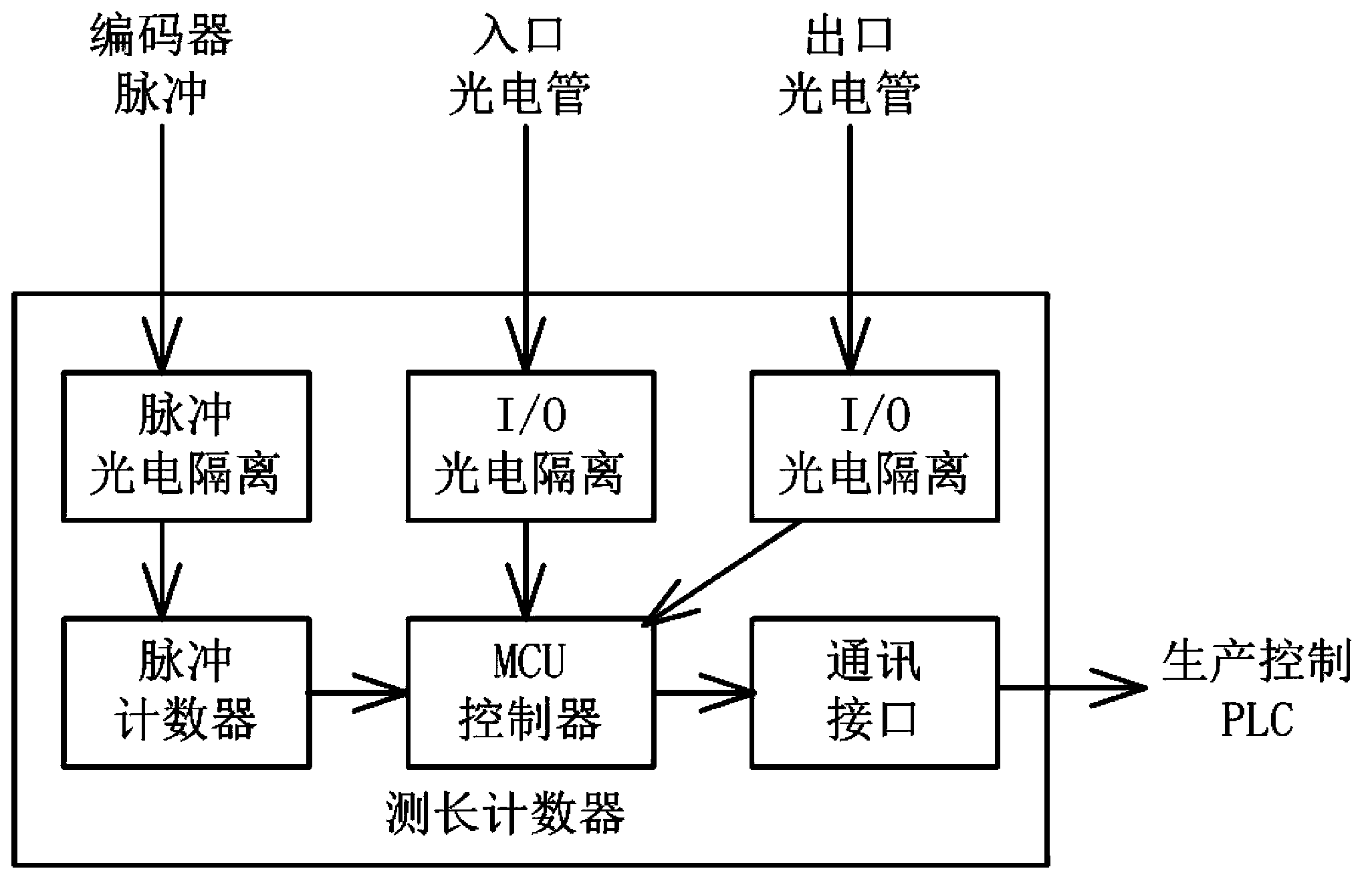

Casting blank length precision measuring device and method

InactiveCN103913140AAccurate measurementHigh measurement accuracyMeasurement devicesMeasurement deviceEngineering

The invention discloses a casting blank length precision measuring device which comprises a roller way, a counter, a processor, an inlet sensor and an outlet sensor. The inlet sensor and the outlet sensor are placed at the two ends of the roller way respectively, the distance between the inlet sensor and the outlet sensor is D, the length of a casting blank is L, and the difference between D and L is space distance difference Dt. By measuring the space distance difference Dt, the length the casting blank is obtained by conversion according to the distance D. The error of Dt is far smaller than the error of the measured length L of the casting blank, and the precision of the casting blank length L obtained by conversion of the space distance difference Dt is higher than the directly-measured casting blank length L. A casting blank length precision measuring method comprises the steps that the inlet sensor and the outlet sensor are arranged at the two ends of the roller way, and the distance D between the inlet sensor and the outlet sensor is measured in advance; when the casting blank passes through the inlet sensor and the outlet sensor, triggering signals are generated, the counter carries out counting according to the triggering signals, and a counting result Dt is sent to the processor; and the processor computes the length L of the casting blank according to the distance D and the counting result Dt.

Owner:BAOSHAN IRON & STEEL CO LTD

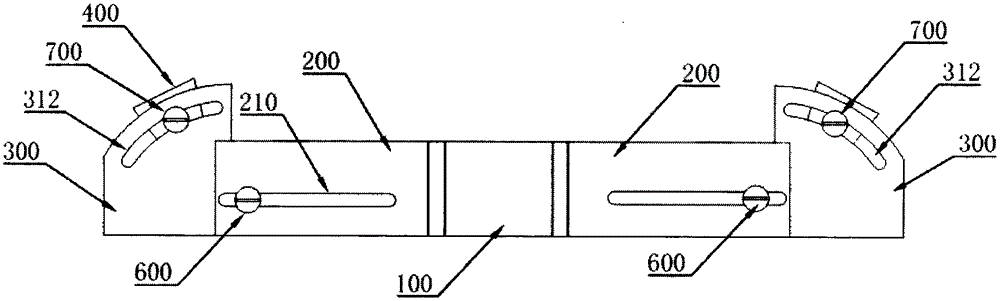

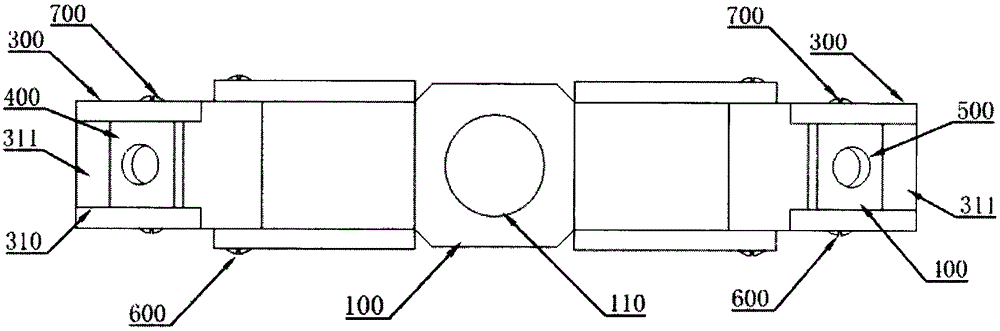

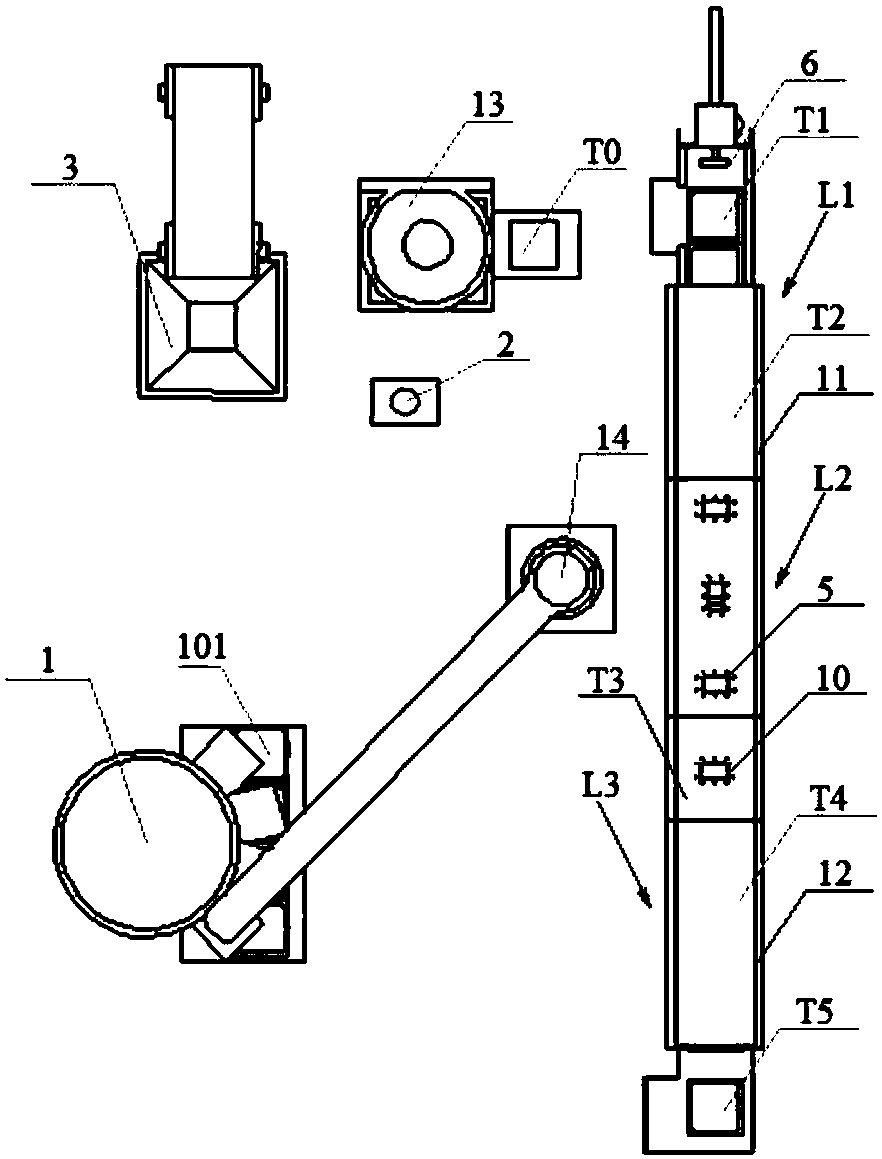

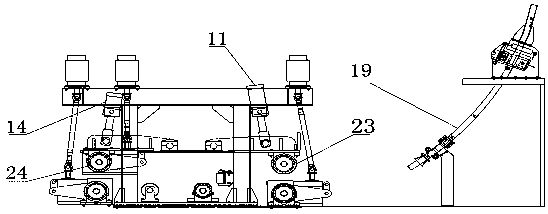

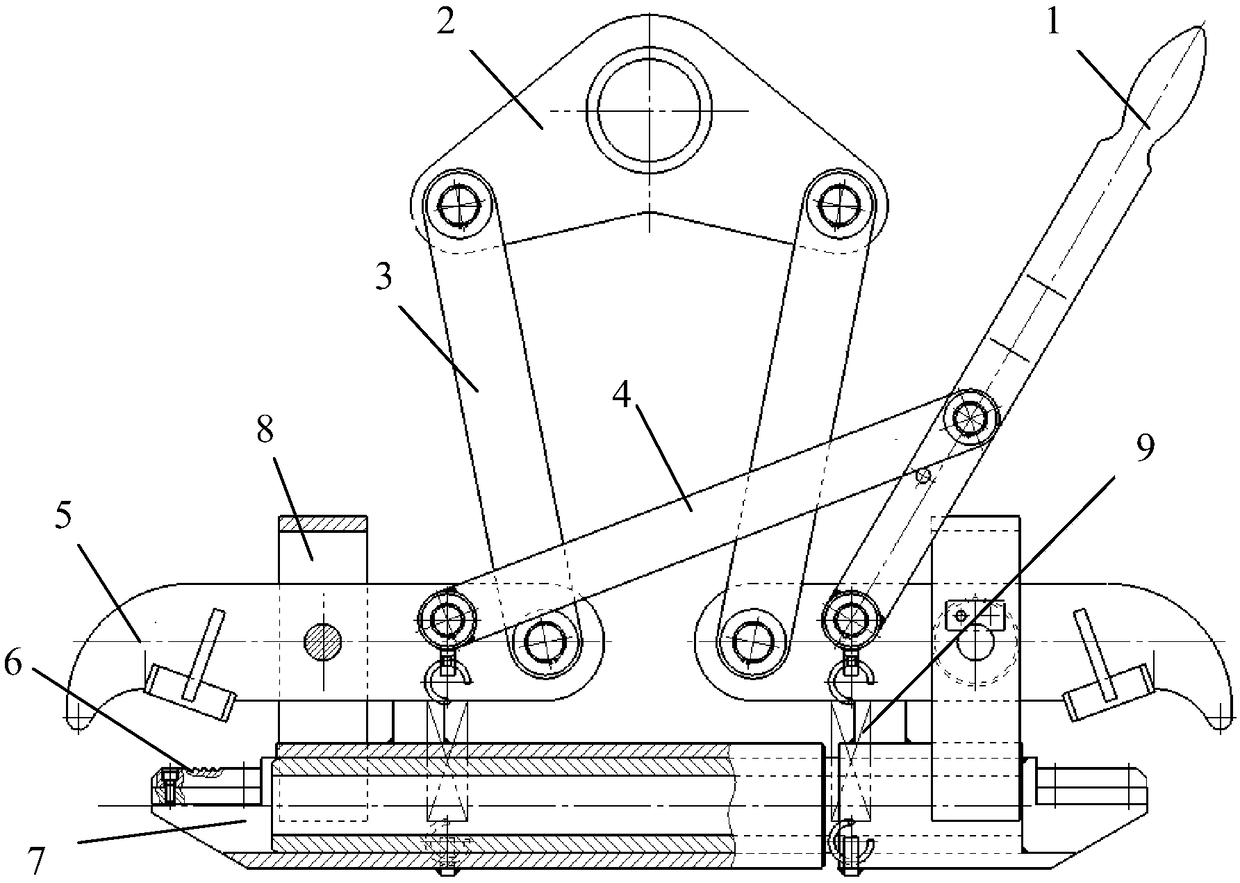

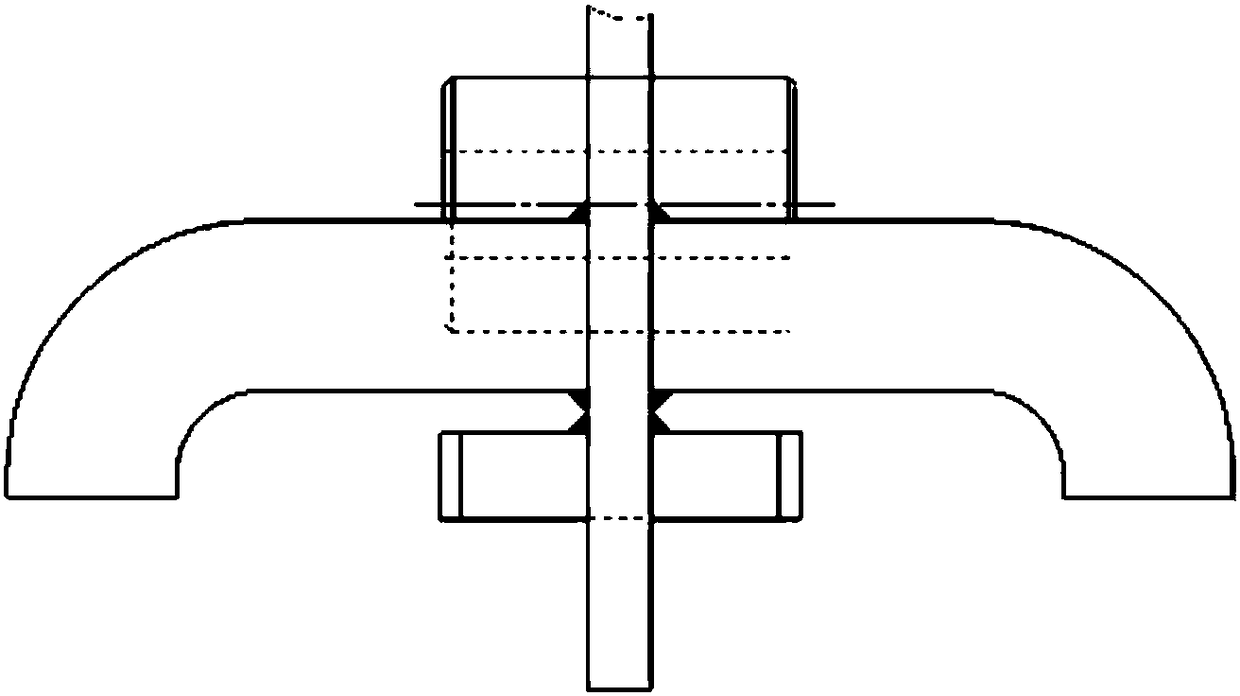

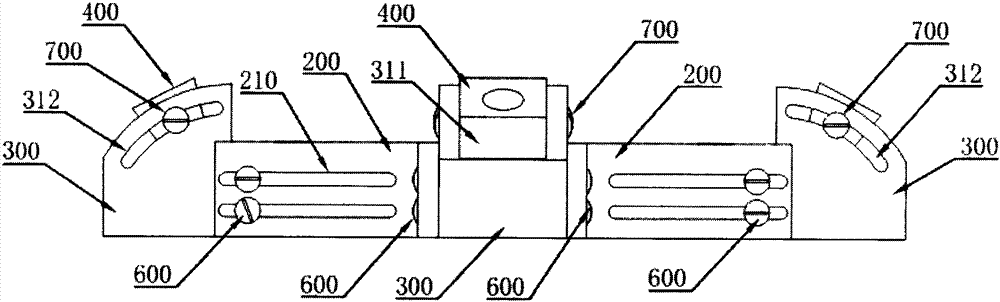

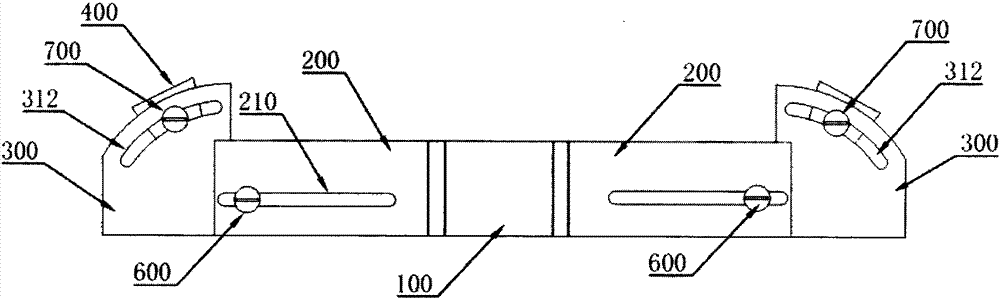

Ultrasonic-wave stress detection device capable of adjusting acoustic beam angle and test area

ActiveCN105300578AAchieving Residual Stress TestingSatisfy customersForce measurementBeam angleHeat-affected zone

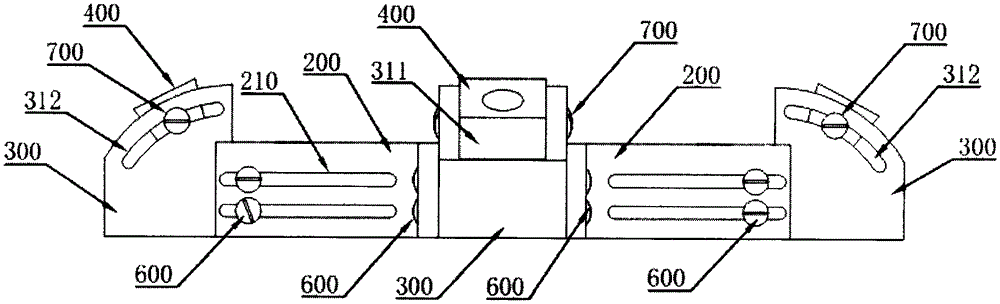

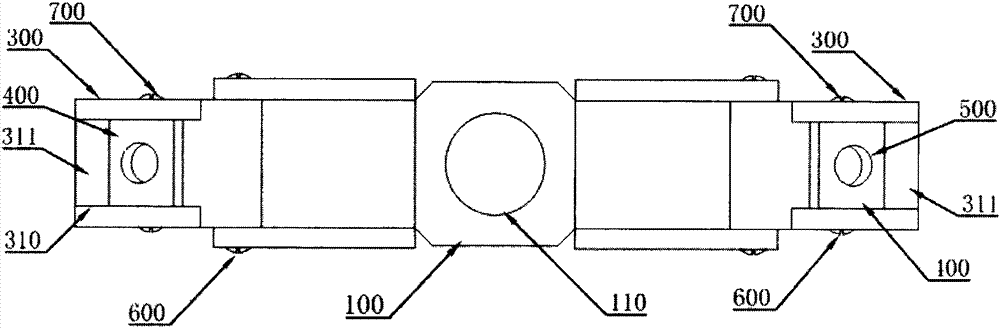

Provided is an ultrasonic-wave stress detection device capable of adjusting an acoustic beam angle and a test area. The detection device comprises a center positioning bench (100). Parallel guide rail racks (200) are fixed on opposite side faces of the center positioning bench (100) and are slidably connected with a glass pedestal (300). A U-type groove rail (310) with a protruding arc guide rail face (311) is arranged on the upper part of the glass pedestal (300). A probe fixing wedge (400) is slidably connected with the side wall of the U-type groove rail (310). The recessed arc face of the probe fixing wedge (400) cooperates with the protruding arc guide rail face (311) of the U-type groove rail (310). A probe fixing cavity (500) used for fixing an ultrasonic-wave probe is arranged on the upper part of the probe fixing cavity (500). According to the invention, adjustment and correction of first critical angles of a welded seam and of a heat affected zone and residual stress tests for different kinds of materials can be achieved; and residual stress tests of to-be-tested workpieces in different areas of regions can be achieved.

Owner:SOUTHWEST JIAOTONG UNIV

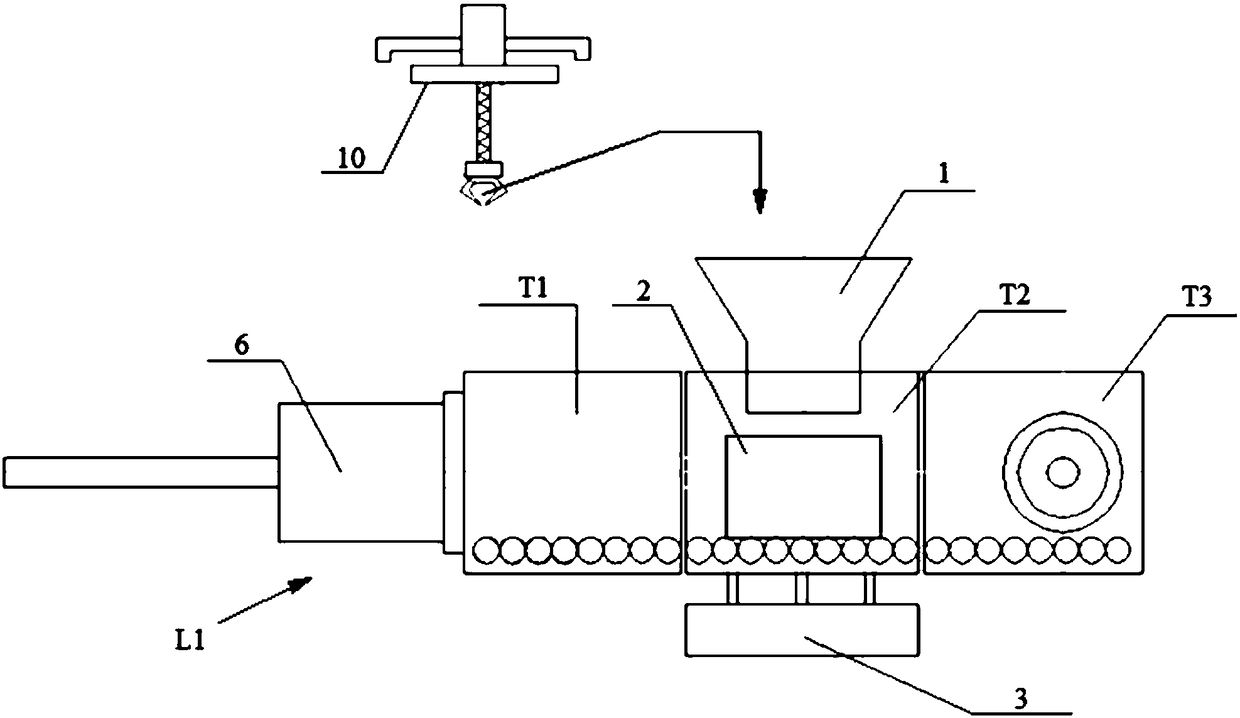

On-line intelligent detection device and method for particle size of sintering fuel

PendingCN109297873AImprove the level of intelligenceOnline automatic implementationWeighing by removing componentPreparing sample for investigationMicrowaveEngineering

The invention discloses an on-line intelligent detection device for the particle size of sintering fuel. The on-line intelligent detection device comprises three sequentially-communicating sliding ways, a powerful vibrating screen, a first weighing device and a discharging bin, an intelligent robot and a feeding station, wherein the powerful vibrating screen, the first weighing device and the discharging bin are arranged at the side parts of the sliding ways; one end of the second sliding way of the three sliding ways communicates with the first sliding way, and the other end of the second sliding way communicates with the third sliding way; a plurality of loading containers are placed on the three sliding ways, the first sliding way is divided into a first area and a second area serving as a first microwave suppression station, and the second area communicates with the second sliding way; and the second sliding way serves as a microwave drying area, a plurality of first microwave sources are arranged at the top of the second sliding way, and the third sliding way is divided into a third area serving as a microwave drying judging station, a fourth area serving as a second microwavesuppression station and a fifth area. According to the on-line intelligent detection device, the moisture content and the particle size composition of the sintering fuel can be detected in real time,quick, on line and precisely, and field sintering production is guided in real time.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

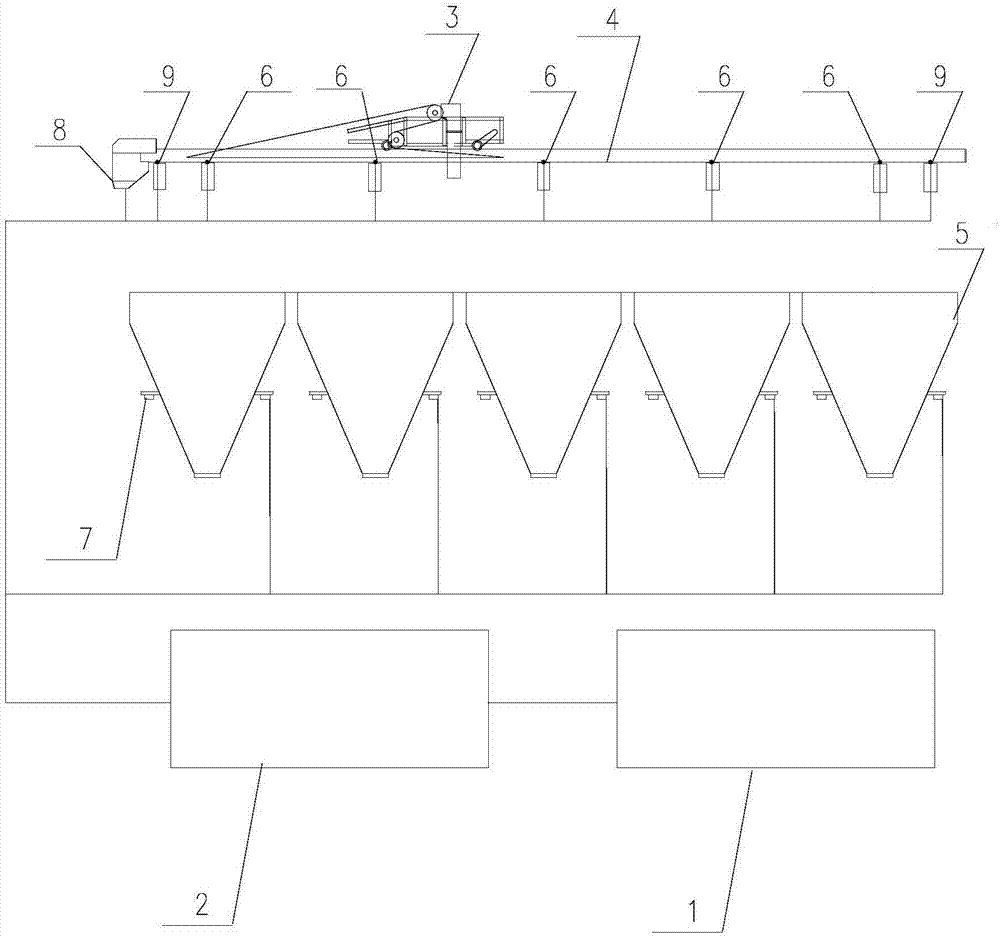

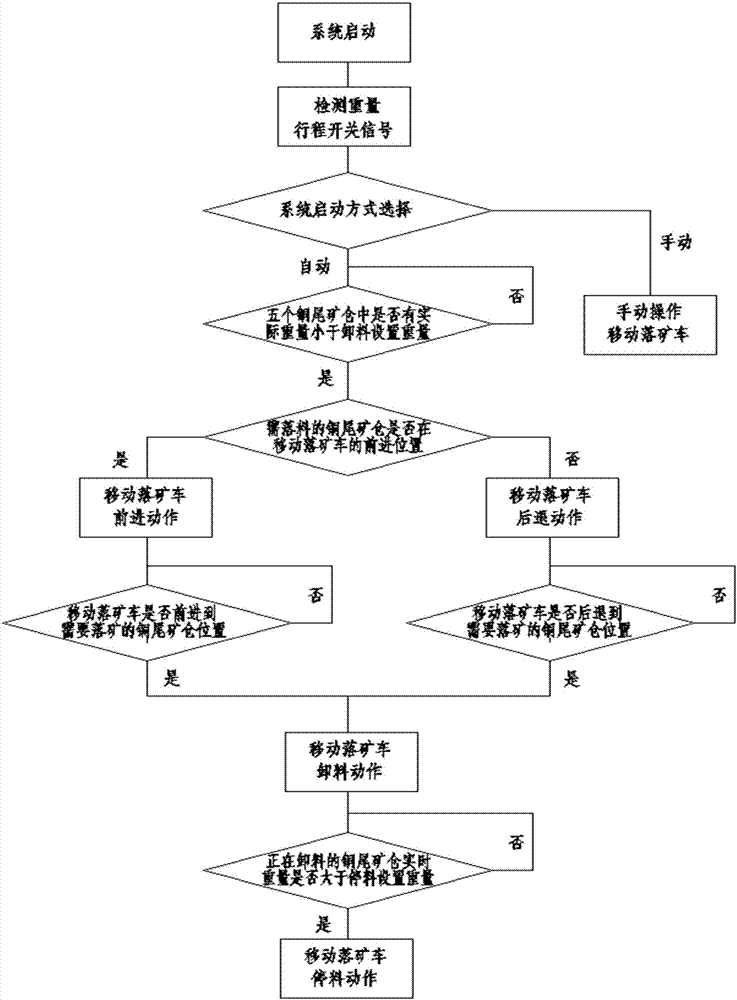

Automatic dropping control system and control method for mobile ore dropping vehicle

PendingCN107381086ATime-consuming and labor-intensive solutionEasy to operateLarge containersLoading/unloadingHuman–machine interfaceProgrammable logic controller

The invention discloses an automatic dropping control system and a control method for a mobile ore dropping vehicle. The automatic dropping control system comprises a human-computer interface, a PLC (Programmable Logic Controller), the mobile ore dropping vehicle, a rail, ore pockets, travel switches and weighing sensors, wherein the ore pockets are distributed in a straight line; the rail is arranged above the ore pockets; the travel switches are arranged on the rail; one travel switch corresponds to one ore pocket; the distance between each two adjacent travel switches is not larger than the length of the mobile ore dropping vehicle; the weighing sensors are arranged on the peripheries of the ore pockets; and the PLC is used for receiving signals of the travel switches and the weighing sensors, marking the ore pockets to be dropped, sending moving, dropping and stopping commands to the mobile ore dropping vehicle, and displaying a detection status on the human-computer interface. According to the automatic dropping control system and the control method for the mobile ore dropping vehicle provided by the invention, the PLC is utilized for automatically controlling the mobile ore dropping vehicle, the operation is carried out simply and conveniently, the problem that the loss is generated due to process interruption caused by manual operation negligence such as forgetting supplementary is solved, the production need is met, the manpower resource is saved, the manless production is realized, and an automatic mode and a manual mode can be selected for use according to the needs.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

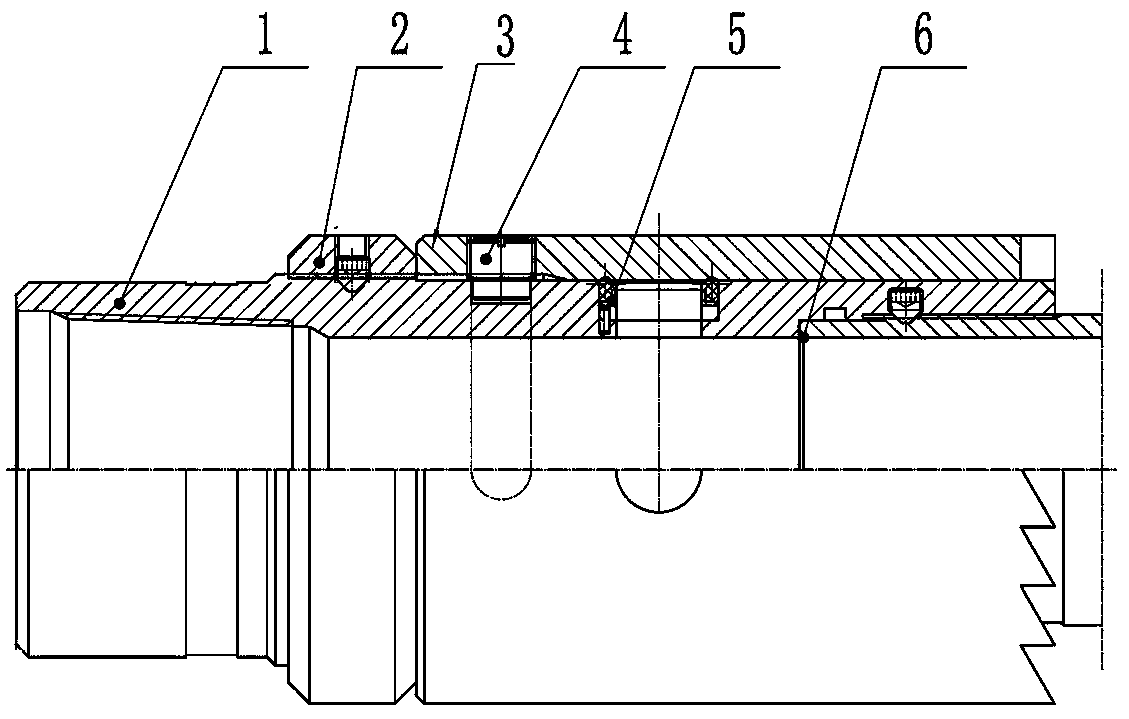

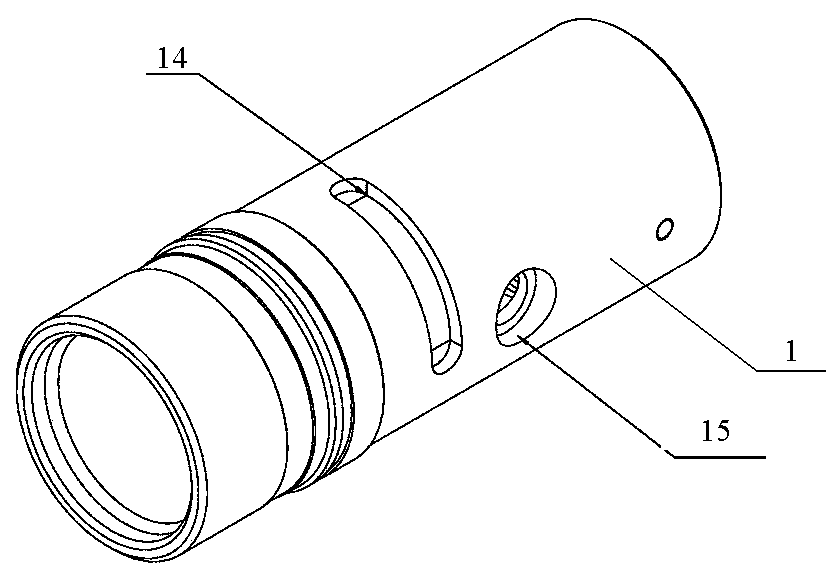

Large orifice releasing packer

The great diameter and great span back-off packer as one water shut-off and pendent tool for oil well consists of one loading assembly and one packer assembly mainly. After the loading assembly and the packer assembly are lowered to the required depth and the well head is set, clear water is pumped to pressurize, the piston in the loading assembly pushes the sealing and anchoring unit in the packer assembly via the shearing pin to anchor and lock. Then, the loading assembly is separated from the packer assembly automatically. The present invention has great shut-off span, great inner diameter, stable sealing, firm anchoring and other advantages.

Owner:欧连贵 +1

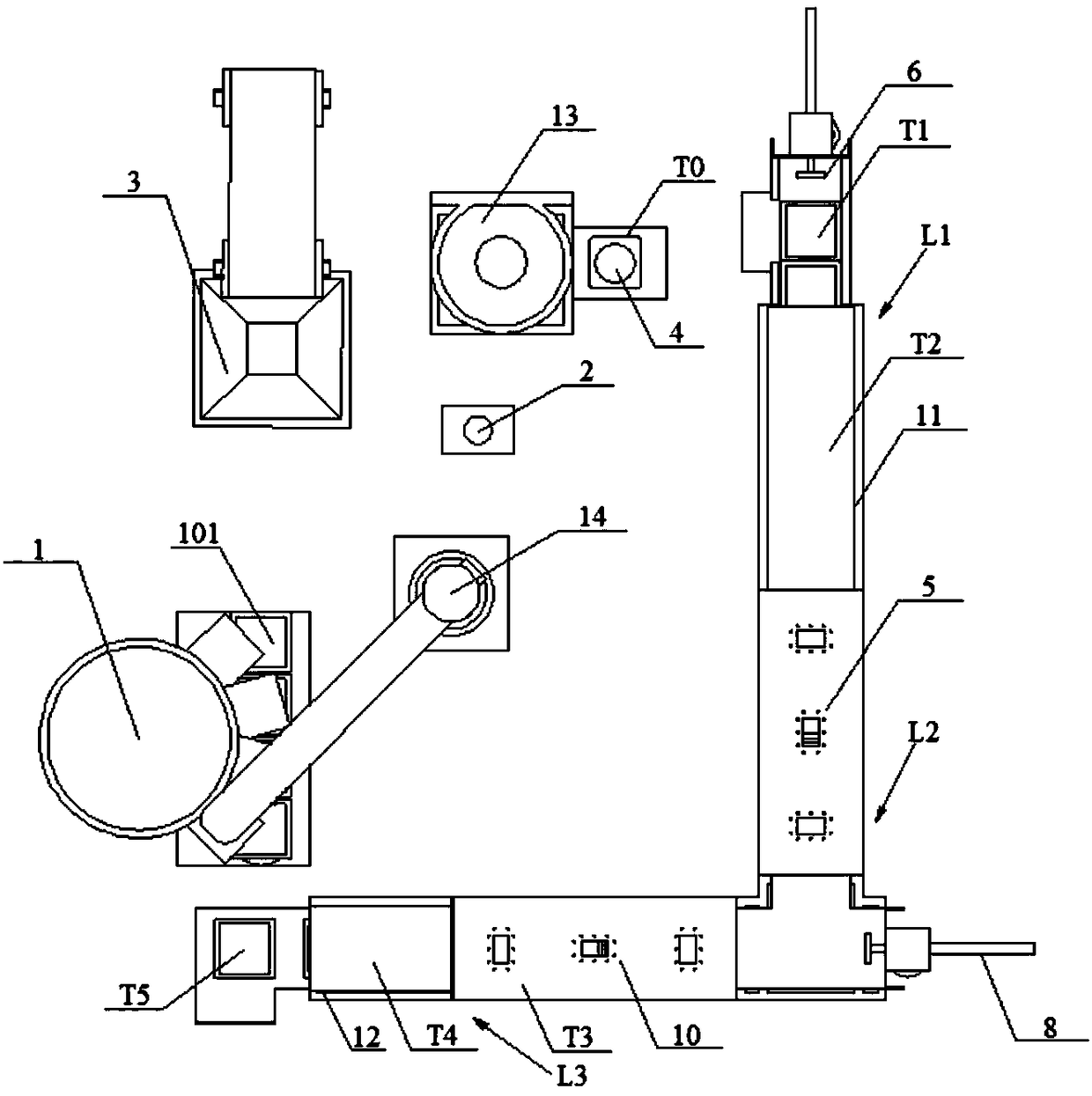

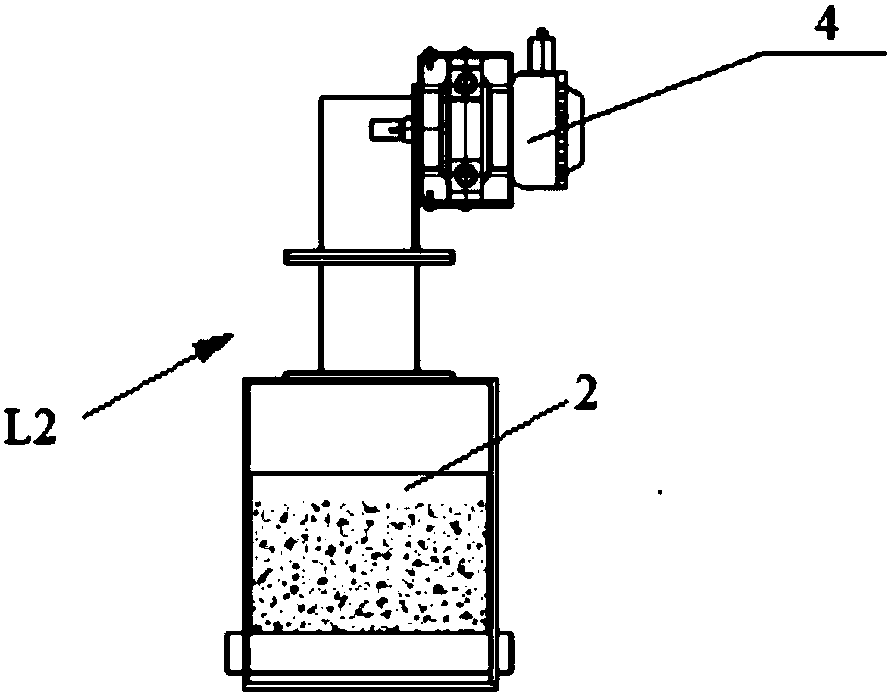

An online moisture detection device and method for a bulk material

PendingCN108663281AOnline real timeReal-time online detectionWeighing by removing componentPreparing sample for investigationMicrowaveClosed loop

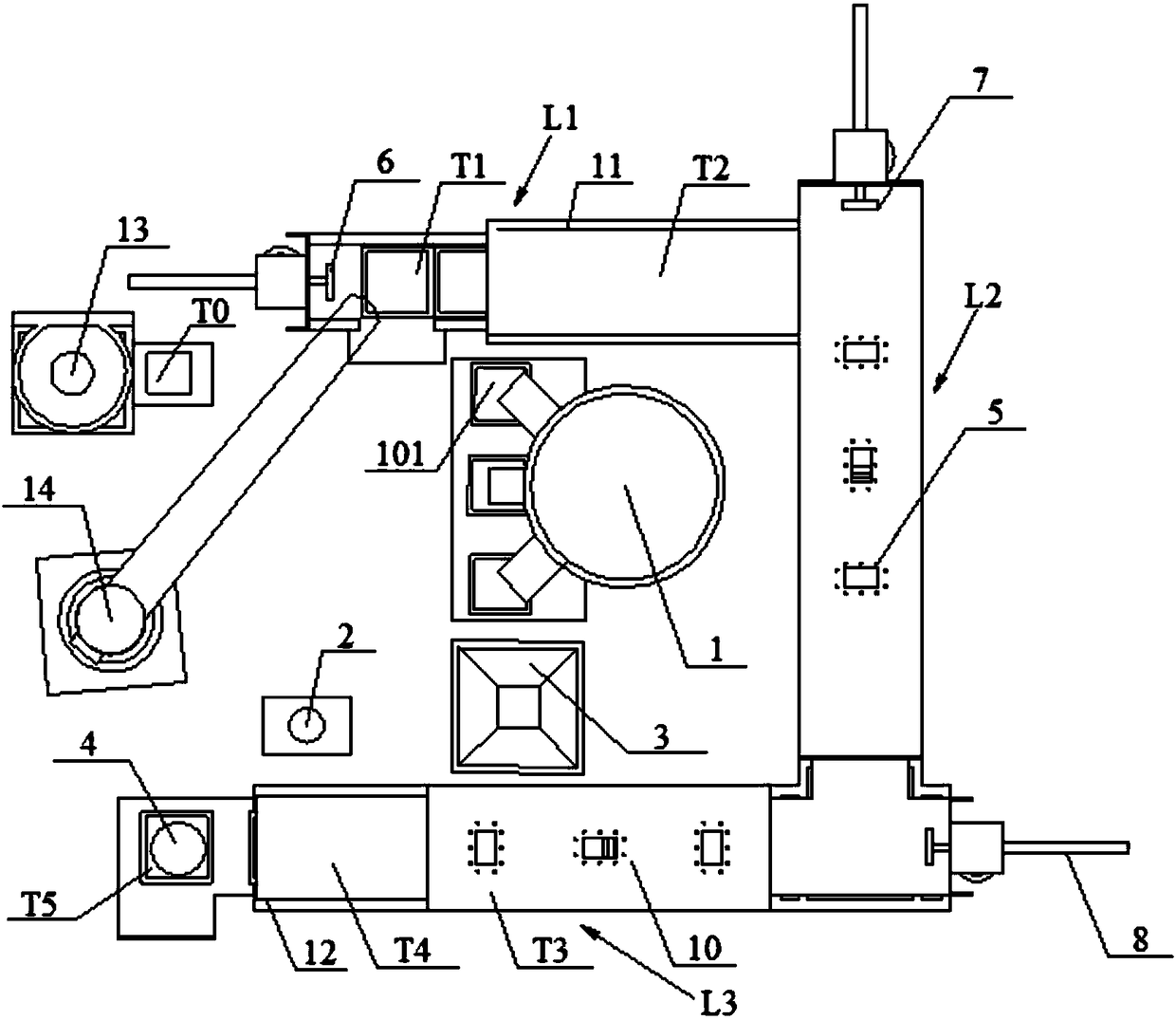

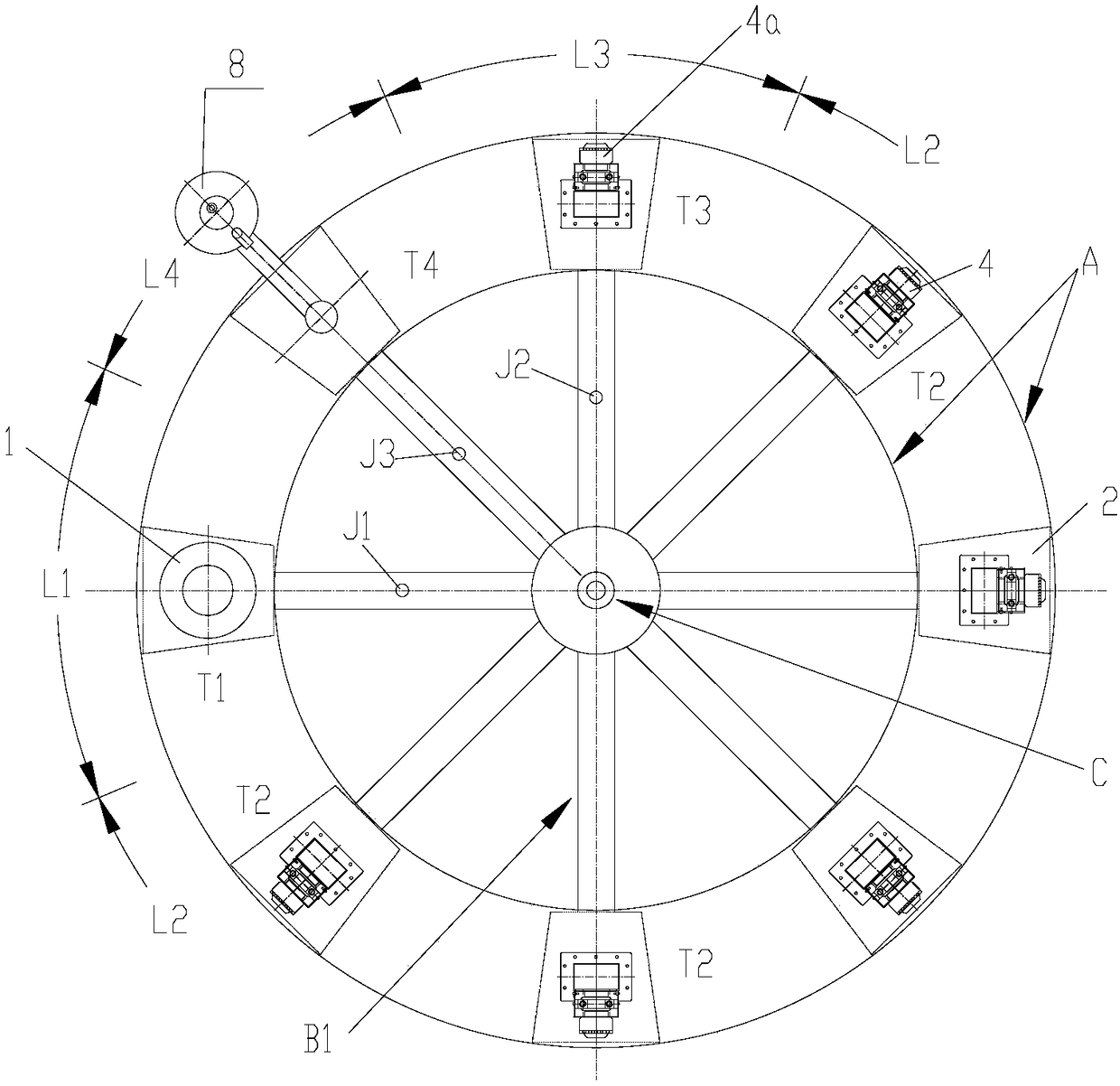

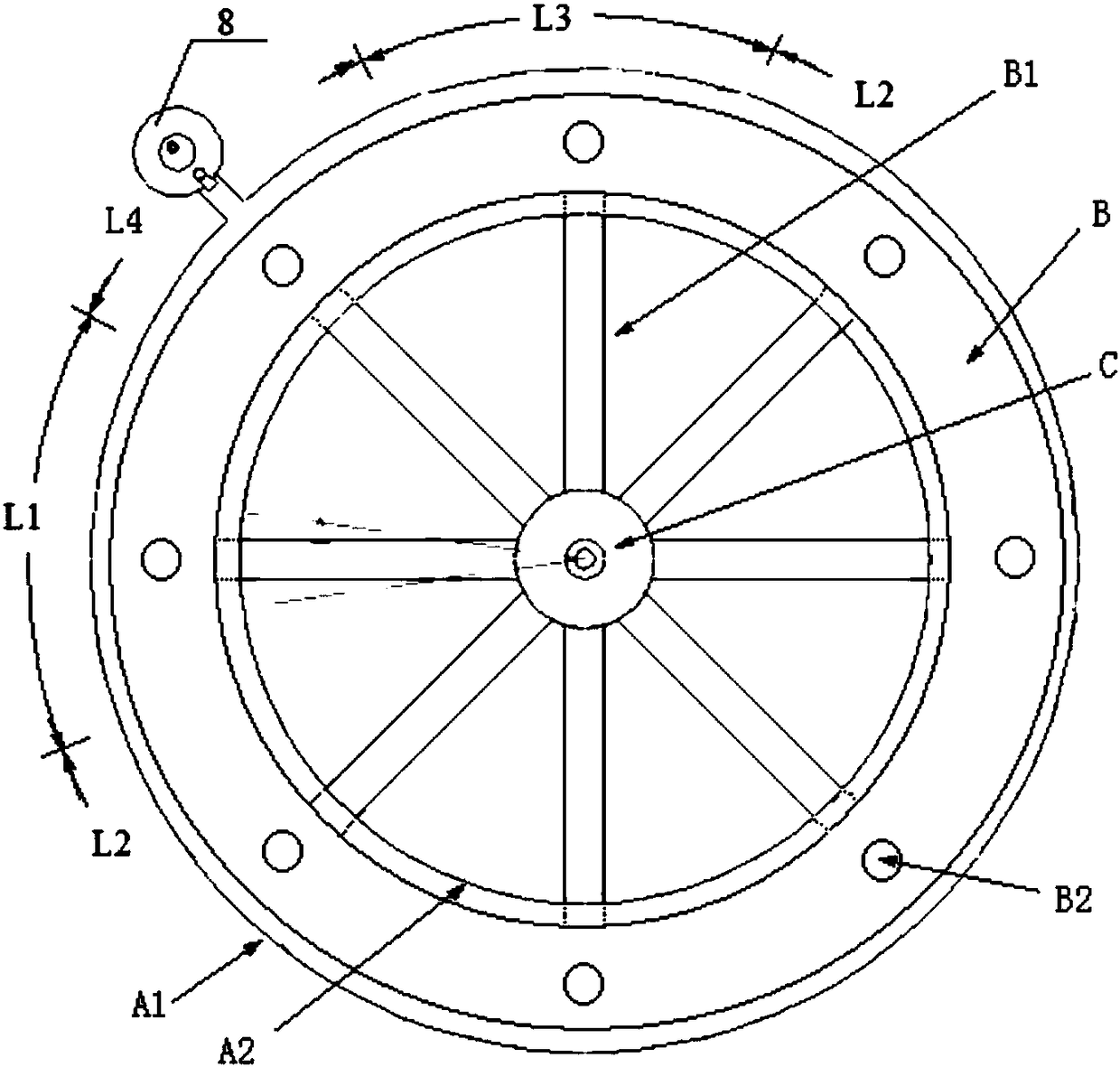

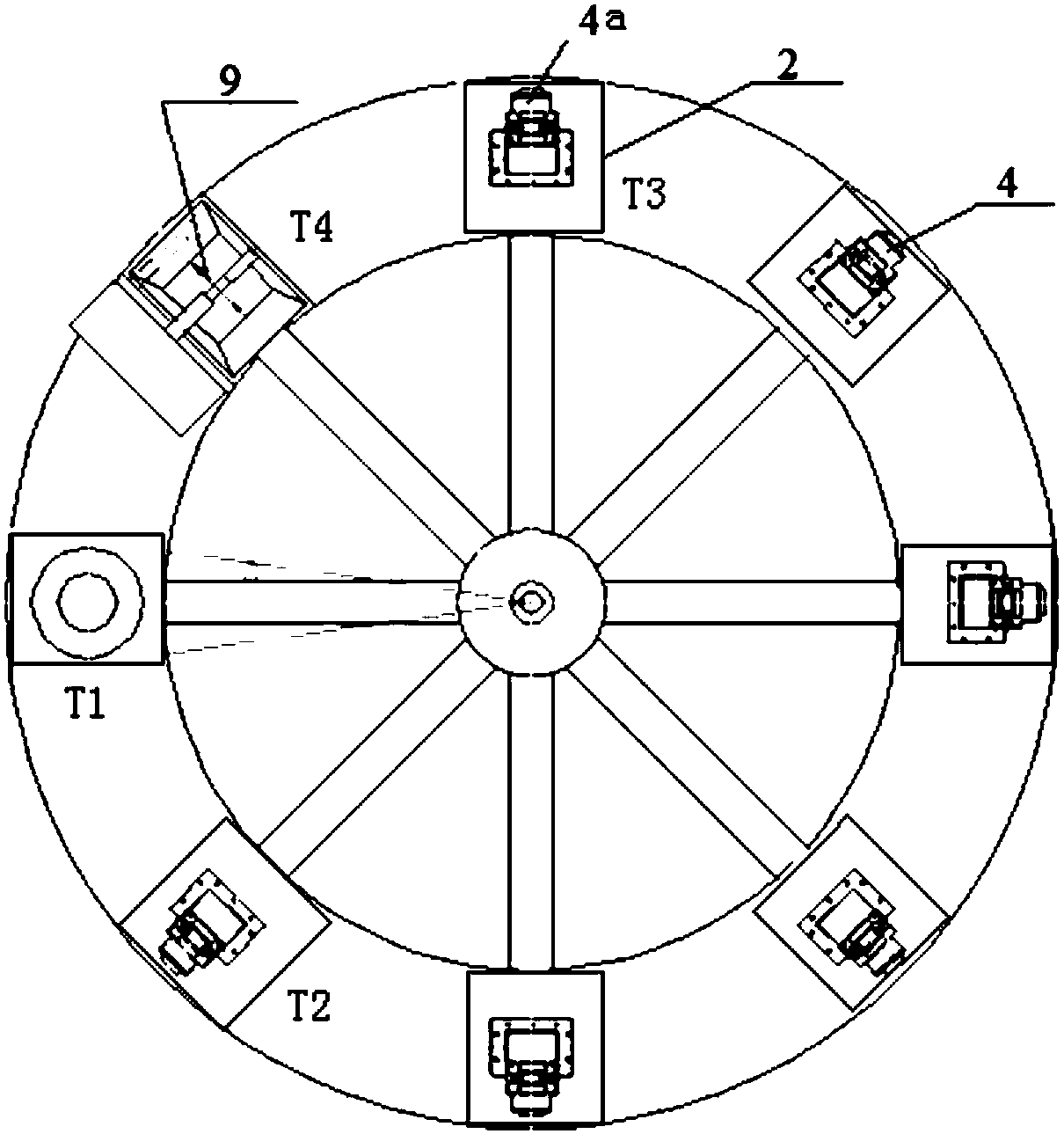

The invention provides an online moisture detection device for a bulk material. The device is characterized in that: the device includes an annular channel in the form of a closed loop, the annular channel is divided into a first section (L1), a second section (L2), a third section (L3), and a fourth section (L4); the annular channel is composed of an annular cover body (A) and an annular bottom plate (B), the annular bottom plate (B) is connected with a driving device (C) through a support bar (B1), multiple through holes (B2) are arranged along the circumference of the annular bottom plate (B) and multiple charging containers (2) are correspondingly placed on these through holes (B2), wherein the first section (L1) is a charging area, the second section (L2) is a microwave drying area, the third section (L3) is a detection area, and the fourth section (L4) is a discharge area. The moisture of different types of the bulk material can be detected in real time, rapidly, online and accurately, the measurement precision can reach the moisture measurement precision of a manual sampling, drying and weighting method, and the existing problem is solved in a large degree.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

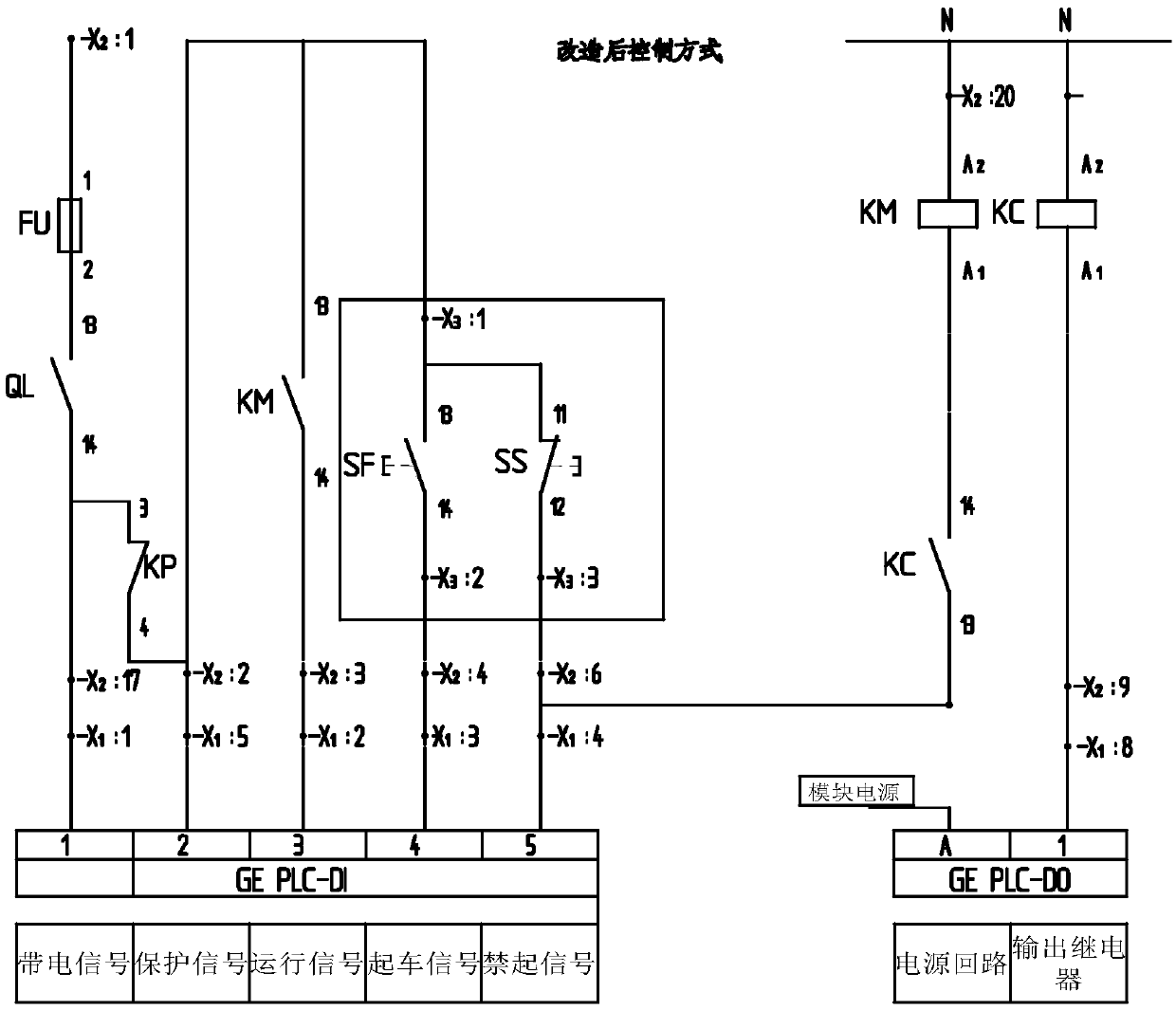

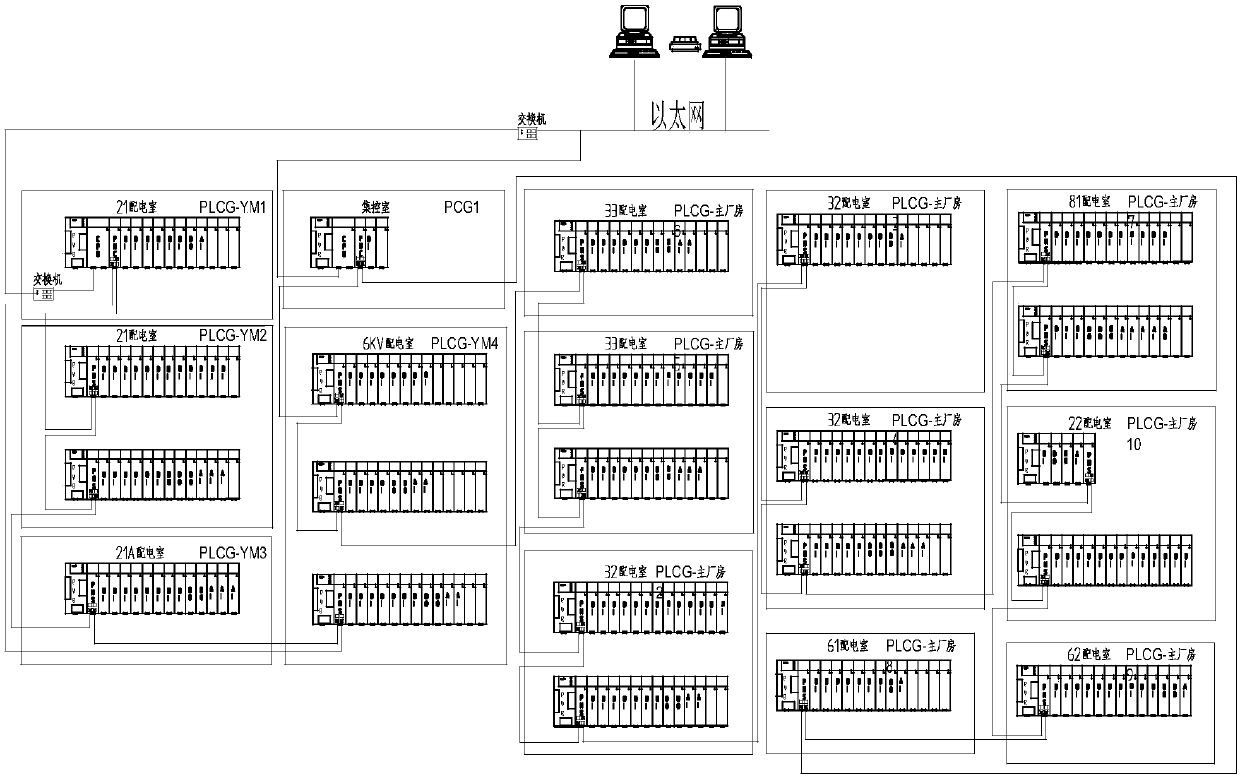

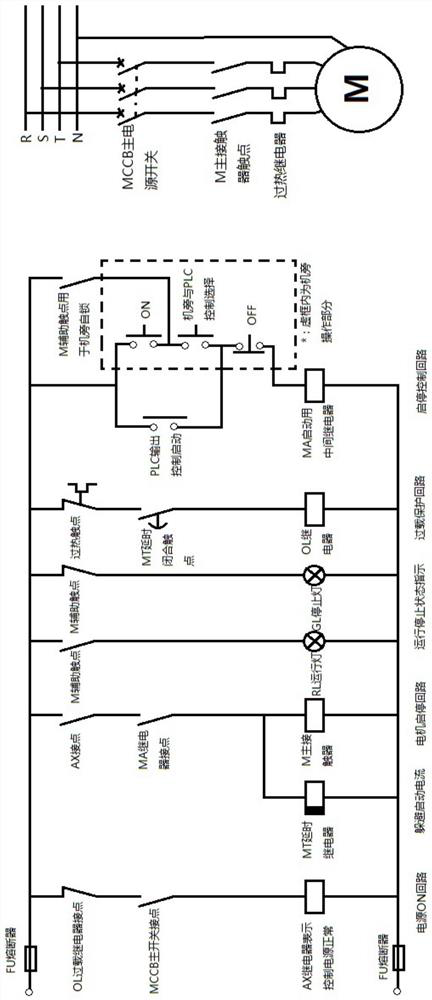

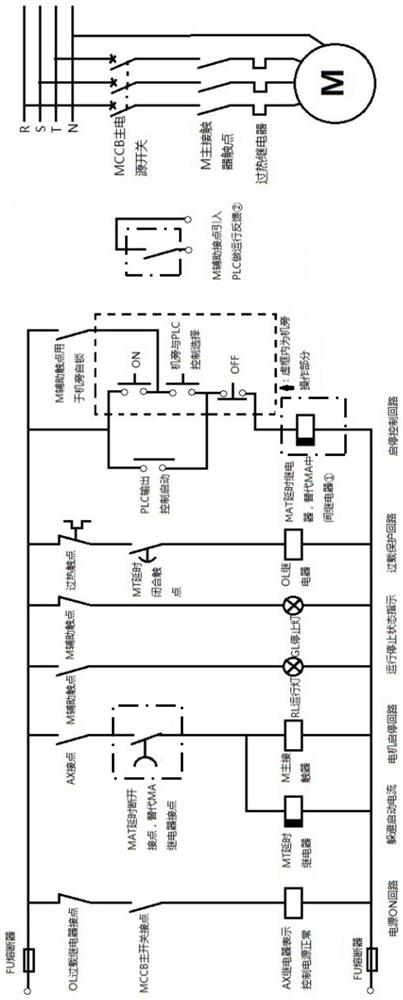

Centralized control system of coal preparation plant

InactiveCN107597417APerfect collection, monitoring and processingImprove stability and reliabilitySolid separationElectricityReal-time data

The invention discloses a centralized control system of a coal preparation plant. The centralized control system is characterized by comprising a centralized control room and substations, wherein thesubstations communicate with the centralized control room, PLC (Programmable Logic Controller) cabinets are respectively installed in the centralized control room and the substations, an upper computer is installed in the centralized control room, lower computers which communicate with the substations are installed on the substations, and an equipment control schematic diagram in each PLC cabinetcomprises a fuse Fu, a breaker QL, a normally-closed protective contact KP, a first relay KM, a start button SF, a stop button SS and a module output second relay KC. Compared with the prior art, thecentralized control system has the following advantages that operating signals such as leakage alarm signals, start fault signals, electric signals, operating signals, shutdown signals and the like can be detected in real time, and current AI data of a motor (above 37 KW) and various material level and liquid level and bin level signals can be detected in real time.

Owner:HUAINAN MINING IND GRP

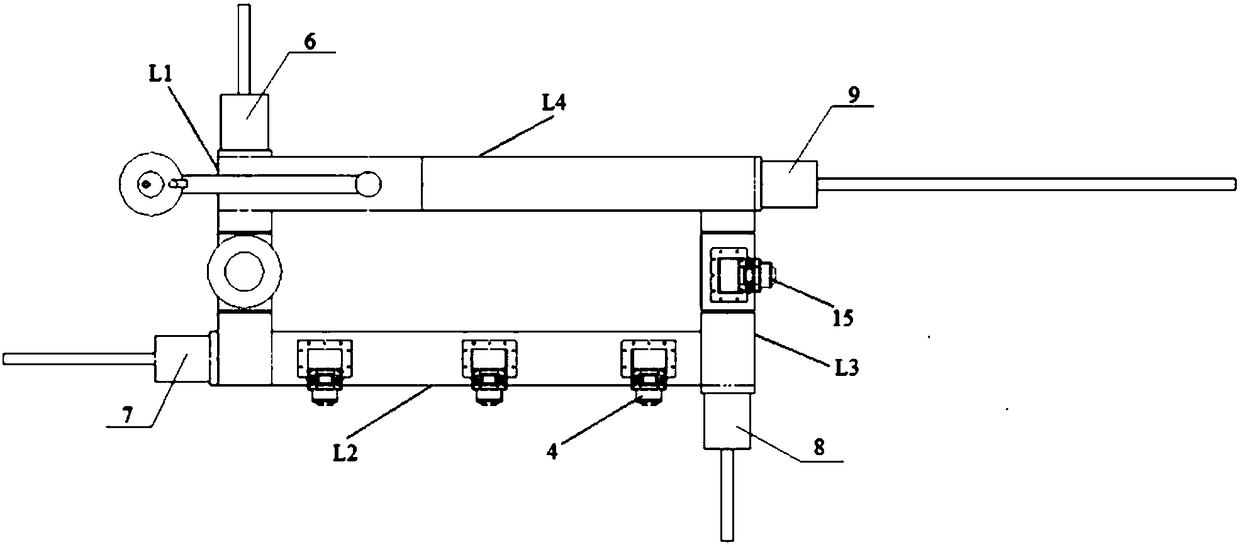

An online moisture detection device and method for a bulk material

PendingCN108663280AOnline real timeReal-time online detectionWeighing by removing componentPreparing sample for investigationMicrowaveClosed loop

The invention provides an online moisture detection device for a bulk material. The device includes four slideways which form a square closed loop, and multiple charging containers (2) are placed in the closed loop; a first slideway (L1) is a charging area, a second slideway (L2) is a microwave drying area, a third slideway (L3) is a detection area, a fourth slideway (L4) is a discharge area; eachslideway is provided with a linear motor with a driving bar, and the linear motors are used for pushing the charging containers (2) to slide from one position to a next position. The moisture of different types of the bulk material can be detected in real time, rapidly, online and accurately, and the measurement precision can reach the moisture measurement precision of a manual sampling, drying and weighting method.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

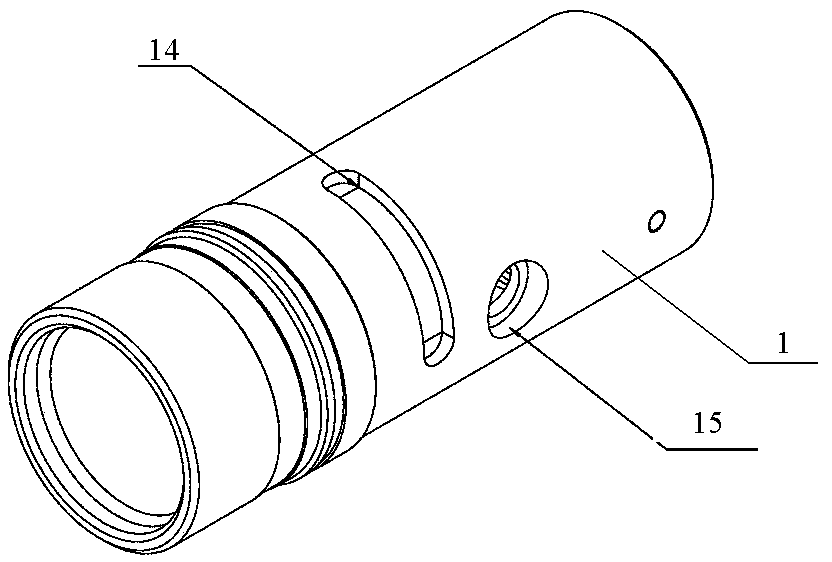

Environment-friendly oil drainage tool for oil pipe

InactiveCN110700791AAvoid pollutionImprove operating conditionsDrilling rodsCleaning apparatusUpper jointScrew thread

The invention relates to an environment-friendly oil drainage tool for an oil pipe. The environment-friendly oil drainage tool comprises a central pipe, wherein the upper end of the central pipe is inthreaded connection with an upper joint; the lower end of the central pipe is in threaded connection with a lower joint; a circumferential strip-shaped hole groove and an oil drainage hole I are formed in the upper joint; the upper joint is in threaded connection with a protection ring; the upper joint is sleeved with a sealing sleeve; the sealing sleeve is provided with a toothed rear end; a pinshaft hole and an oil drainage hole II are formed in the sealing sleeve; the middle part of the central pipe is sleeved with a toothed check ring, a centralizing body main body and a friction block;a guide groove is formed in the rear part of a guide sleeve; a guide pin is arranged on the lower joint and is arranged in the guide groove; the lower end of the lower joint is in threaded connectionwith an anti-collision ring. According to the environment-friendly oil drainage tool, crude oil can be effectively prevented from overflowing from the oil pipe to a wellhead to cause environmental pollution during operation through simple operations such as lifting and rotating, so that the wellhead operation condition is improved.

Owner:LIAONING XINHUA INSTR CO LTD

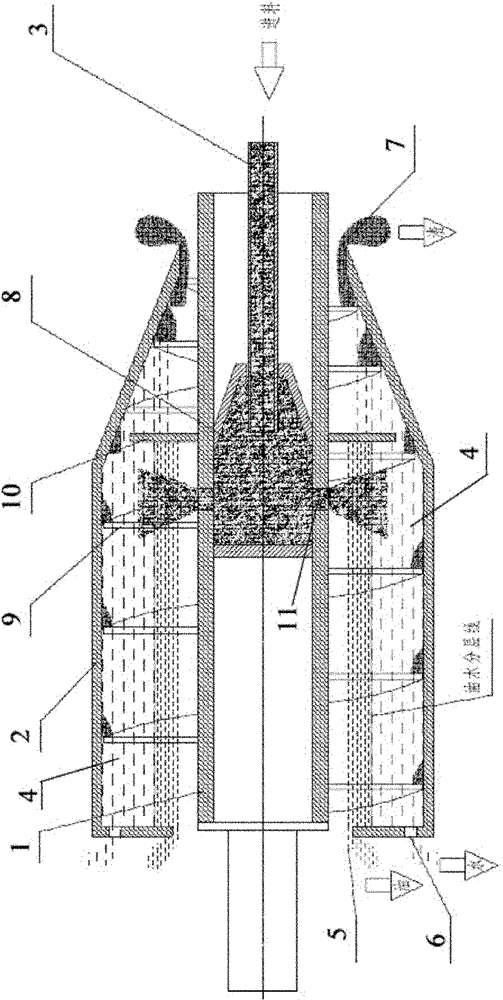

Method for treating ageing oil of viscous oil

ActiveCN102041038BSolve the problem of demulsification and dehydrationIncrease effective storage capacityDewatering/demulsification with chemical meansRotary centrifugesDemulsifierEthylene oxide

The invention relates to a method for treating ageing oil of viscous oil, which provides a demulsifier for ageing oil of viscous oil, comprising the following raw materials in weight percent: 0.5-1% phenol, 1.5-2% styrene, 0.5-1% ethyleneamine, 0.5-1% formaldehyde, 0.5-1% catalyst, 40-50% ethylene oxide and 40-50% epoxypropane. The invention further provides a three-phase decanter centrifuger, comprising a differential mechanism, a spiral propeller, a rotary drum, a housing, an engine base, a motor and a feed pipe. The invention further provides a method for treating ageing oil of viscous oil, comprising the following steps of: using the demulsifier to perform demulsification treatment to the ageing oil of the viscous oil, then inputting the ageing oil of the viscous oil after the demulsification treatment in the three-phase decanter centrifuger to centrifuging and separating so as to respectively obtain fatlute, sewage and the oil. The ageing oil, especially the ageing oil of the viscous oil, is treated by adopting the demulsifier to combine with the centrifuging method; the demulsification and dehydration problem of the ageing oil of viscous oil in the oil field is solved, and the requirement of the field production can be satisfied.

Owner:PETROCHINA CO LTD +1

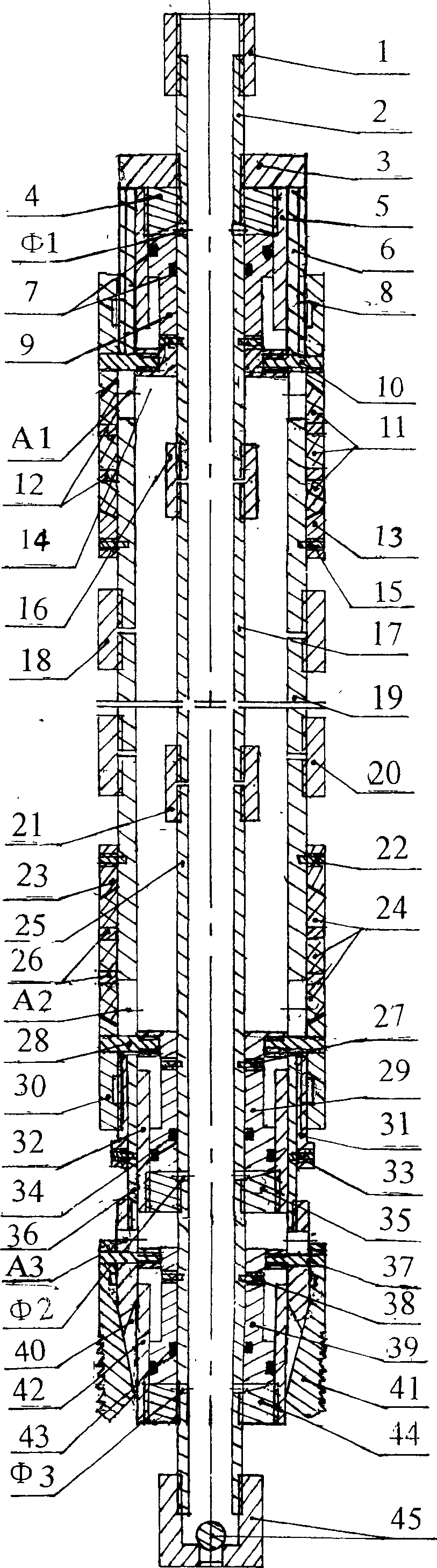

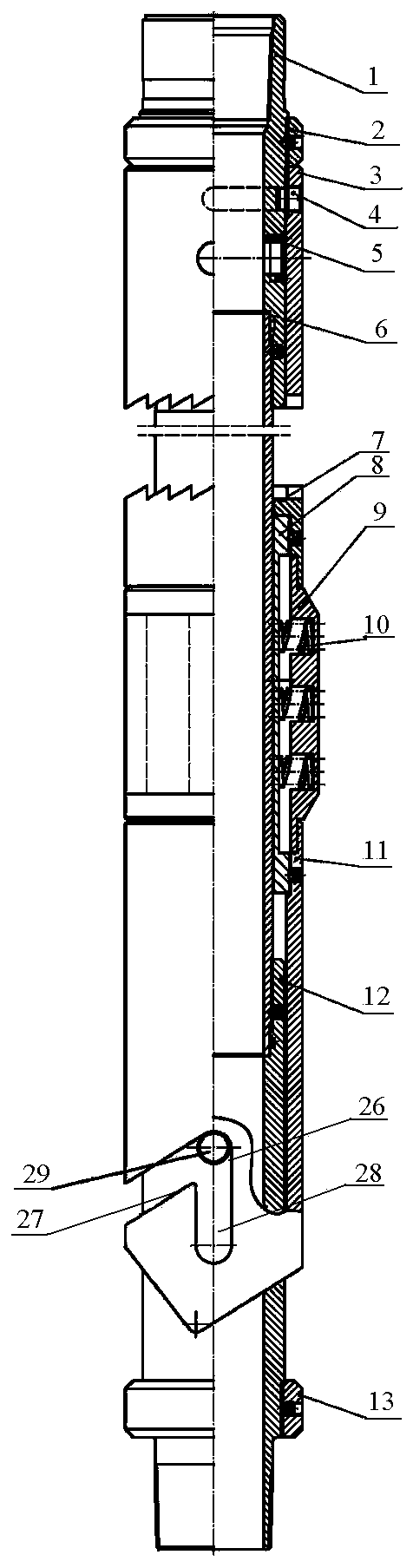

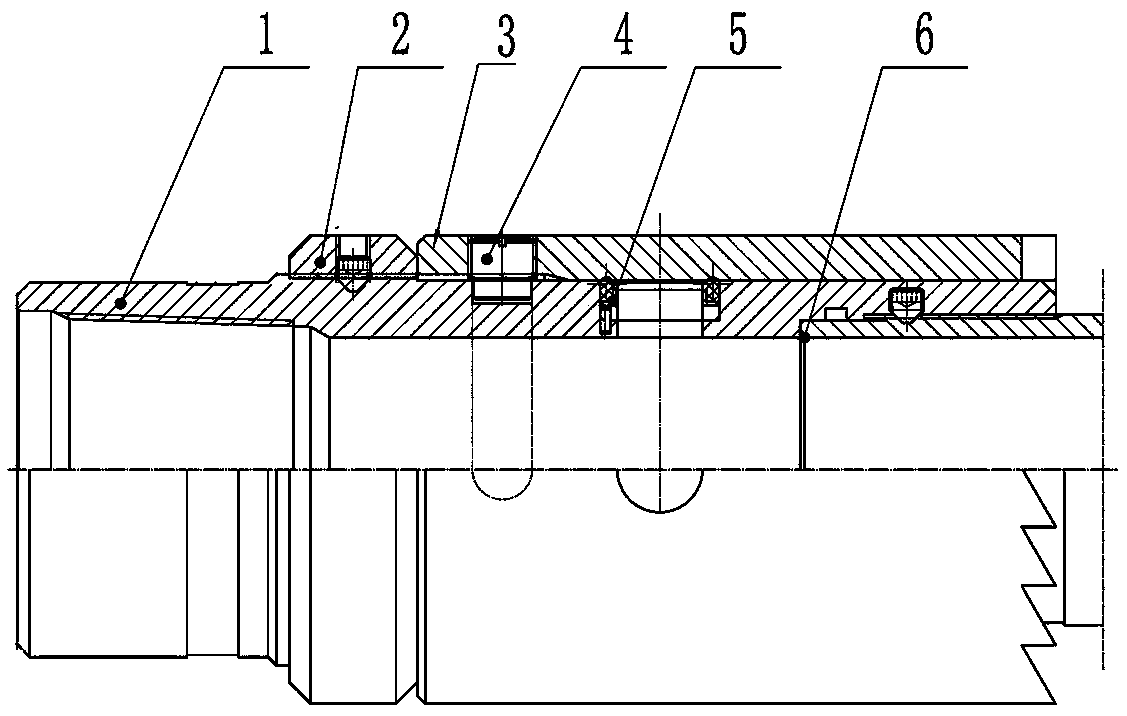

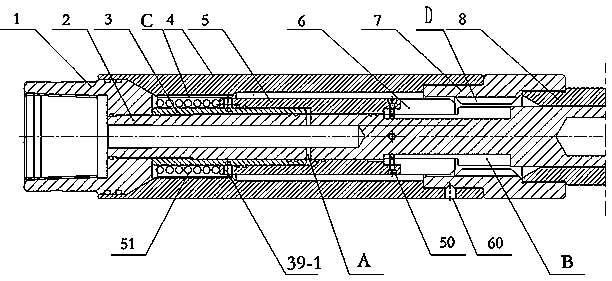

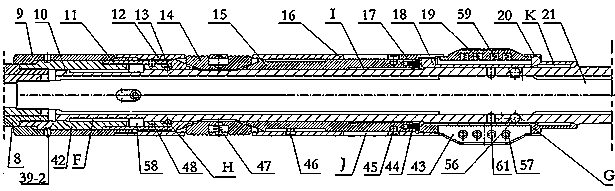

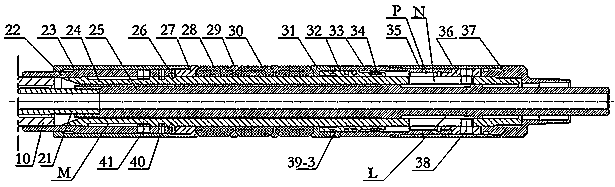

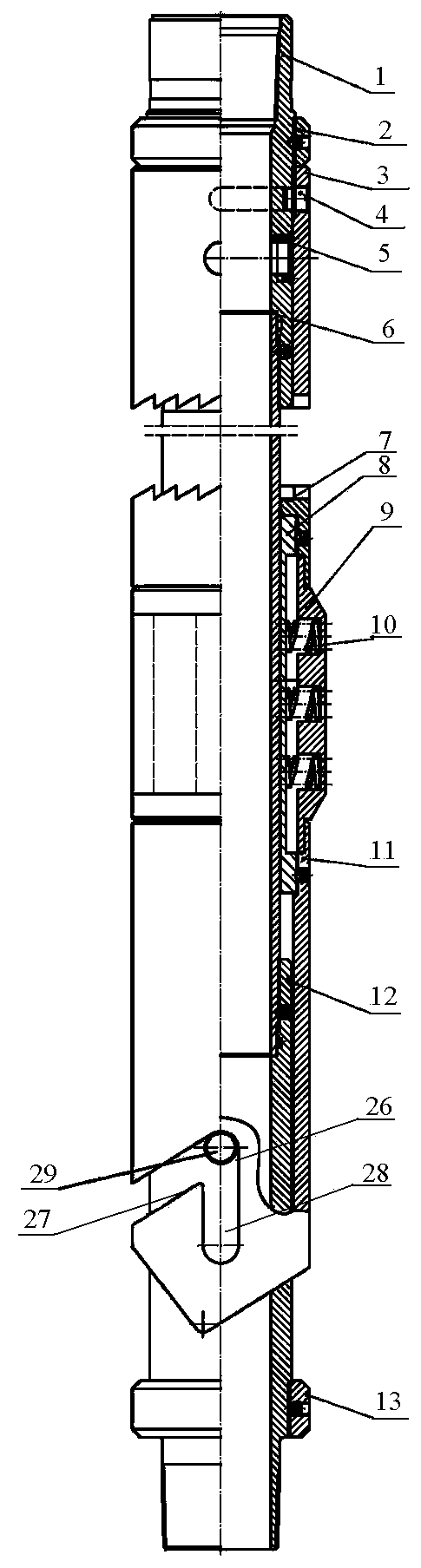

Fracturing anti-roof tool

PendingCN110130851AMeet the needs of on-site productionImprove the blocking effectFluid removalSealing/packingDrive shaftBlock effect

The invention discloses a fracturing anti-roof tool, which comprises an upper drive shaft, a middle drive shaft, a lower drive shaft, an upper center tube, a lower center tube, an upper cone, a lowercone, slips, a side rubber cylinder, a middle rubber cylinder, a release ring, and a lower working cylinder. The fracturing anti-roof tool is characterized in that the fracturing anti-roof tool is connected to a release sleeve in a key mode and put into a key groove of the upper drive shaft; a ball groove is formed in the lower part of the middle drive shaft; a ball hole for placing a steel ball is formed in the upper center tube; the upper cone is fixed to a drive joint by deblocking pins, and the lower part of the upper cone is fixed to a locking ring groove of the upper center tube by usingan upper clamping ring; limit pins connected to the lower cone are located in pin grooves in a guide sleeve, and the inner ends of guide pins connected to the guide sleeve are located in pin groovesof the lower cone; a clamping spring is arranged in an installation groove in a fixing piston, and an inner cylinder of the release cylinder is provided with anti-inverted inclined teeth opposite to the direction of anti-inverted inclined teeth of the clamping spring. The fracturing anti-roof tool can prevent blowout during dismounting, the blocking effect is good, setting is convenient, anchoringis simple and firm, time is saved, the operating cost is lowered, and dismounting is safe.

Owner:LIAONING XINHUA INSTR CO LTD

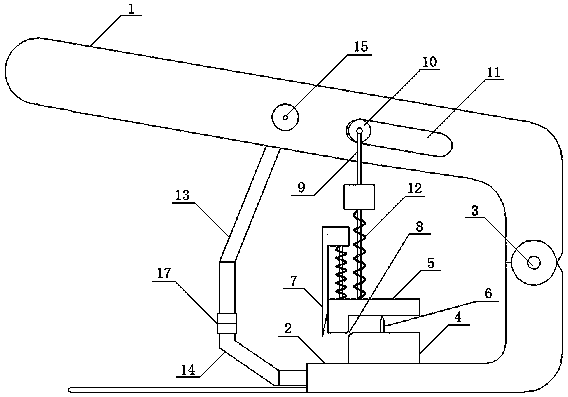

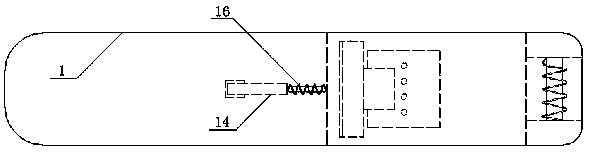

Cutting and stroking device for twisted pair

ActiveCN103401128AGood line effectSimple structureLine/current collector detailsHinge angleEngineering

The invention relates to a cutting and stroking device for a twisted pair. The cutting and stroking device comprises a pedestal, a compression bar, a stroking and cutting device and a cable fixing device. The cutting and stroking device is characterized in that the compression bar is connected with the pedestal through a hinge, and the stroking and cutting device and the cable fixing device are arranged between the compression bar and the pedestal. According to the cutting and stroking device for the twisted pair, two operation links including stroking and cutting can be finished once, the stroking effect is good, and a cable is connected with an RJ45 joint in a compression manner conveniently in the next step; the cutting and stroking device further has the characteristics of simple structure, low manufacturing cost, simplicity and convenience in use and operation and convenience in carrying and can completely meet field fabrication requirements of a twisted pair joint.

Owner:STATE GRID CORP OF CHINA +2

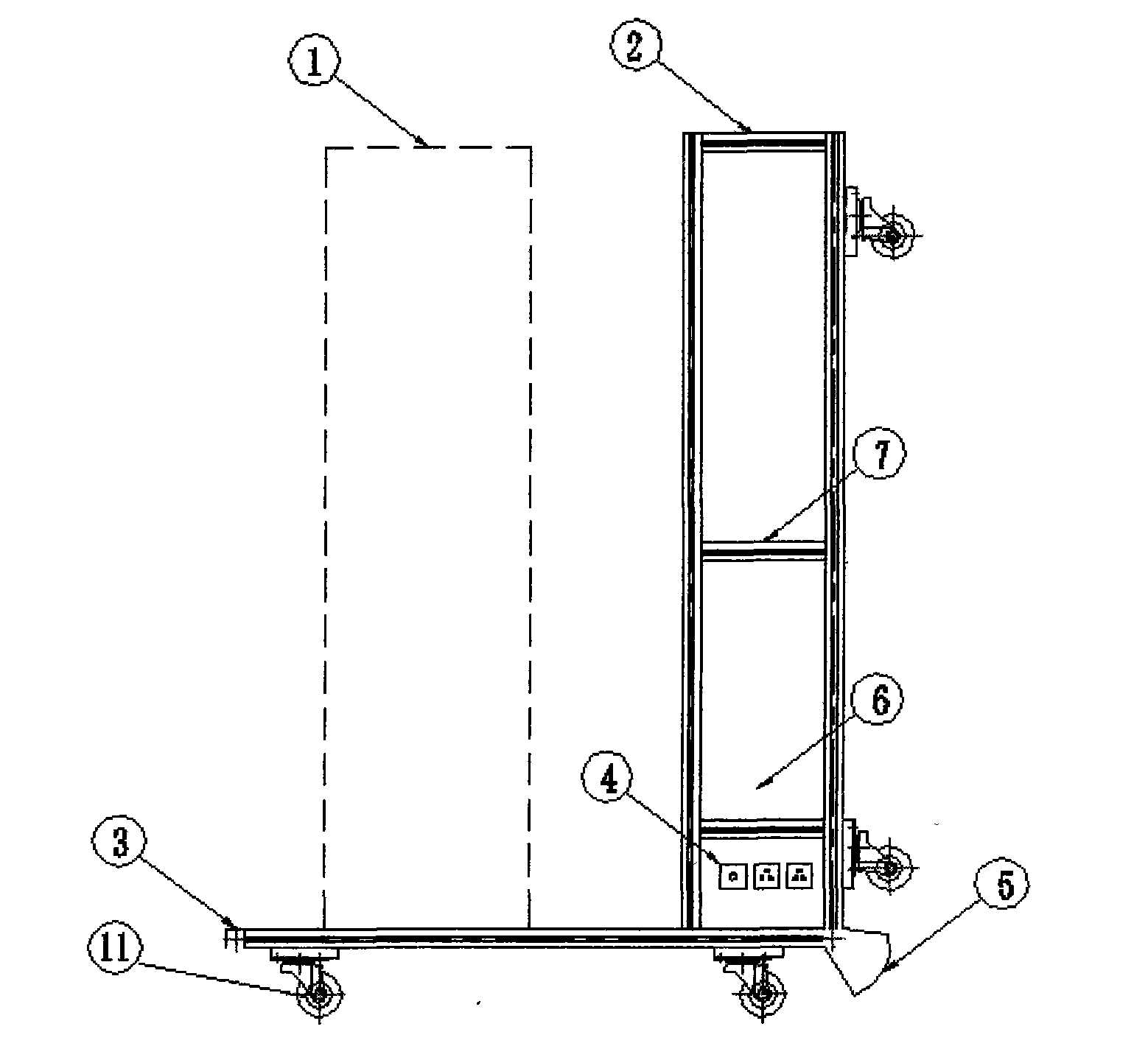

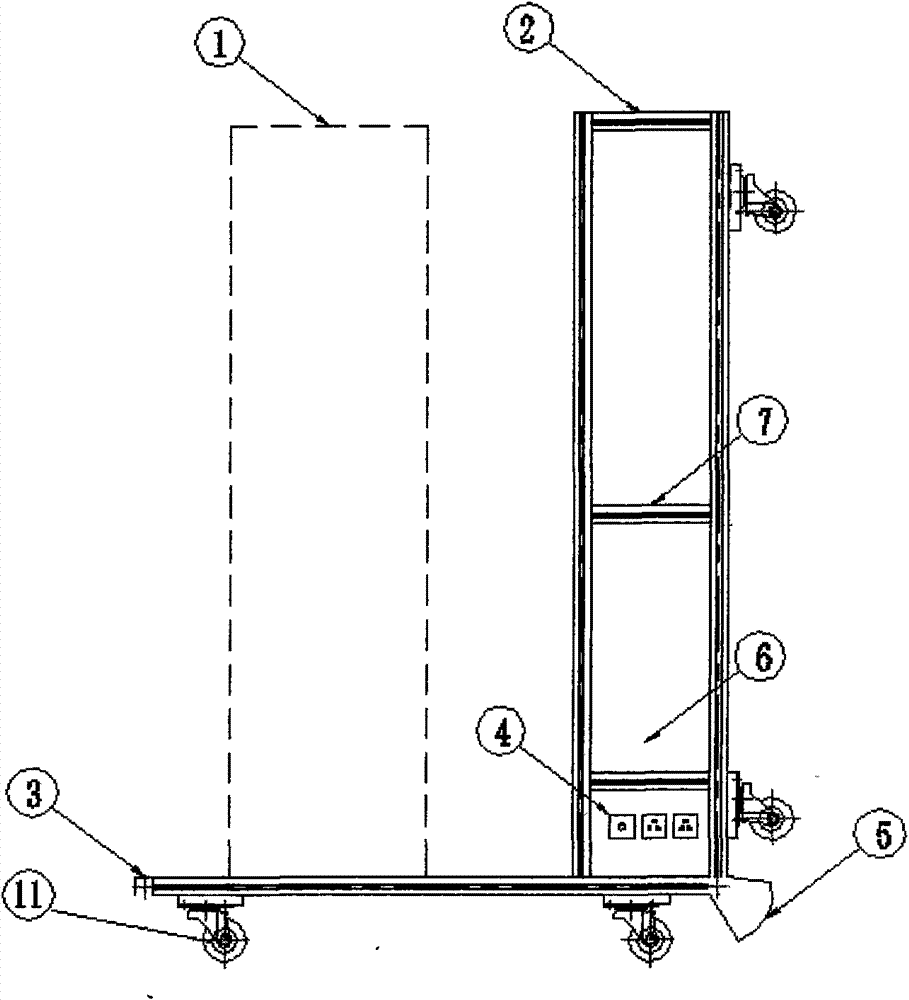

Method and tool for installing large electric vertical-type rectangular cabinet products

ActiveCN101668414AMeet the needs of on-site productionImprove on-site imageSubstation/switching arrangement casingsElectrical componentsEngineeringMechanical engineering

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Oil draining device for tubing

InactiveCN110439506AAvoid pollutionImprove operating conditionsFlushingWell/borehole valve arrangementsUpper jointWellhead

The invention relates to an oil draining device for tubing. The oil draining device comprises a center pipe; the upper end of the center pipe is in threaded connection with an upper joint, and the lower end of the center pipe is in threaded connection with a lower joint; circumferential strip-shaped hole grooves and oil draining holes I are formed in the upper joint, and the upper joint is in threaded connection with a protective ring; a sealing sleeve sleeves the upper joint and is provided with a toothed rear end, and pin shaft holes and draining holes II are formed in the sealing sleeve; atoothed check ring, a centralizer main body and a friction block sleeve the middle of the center pipe; a guiding groove is formed in the rear part of a guiding sleeve, a guiding pin is arranged on thelower joint, and the guiding pin is arranged in the guiding groove; and the lower end of the lower joint is in threaded connection with an anti-collision ring. According to the oil draining device, the situation that during operation, crude oil overflows out of a wellhead from the tubing, and consequently environment pollution is caused can be effectively prevented through easy operations such asupward lifting and rotating, and thus the operation condition of the wellhead is improved.

Owner:LIAONING XINHUA INSTR CO LTD

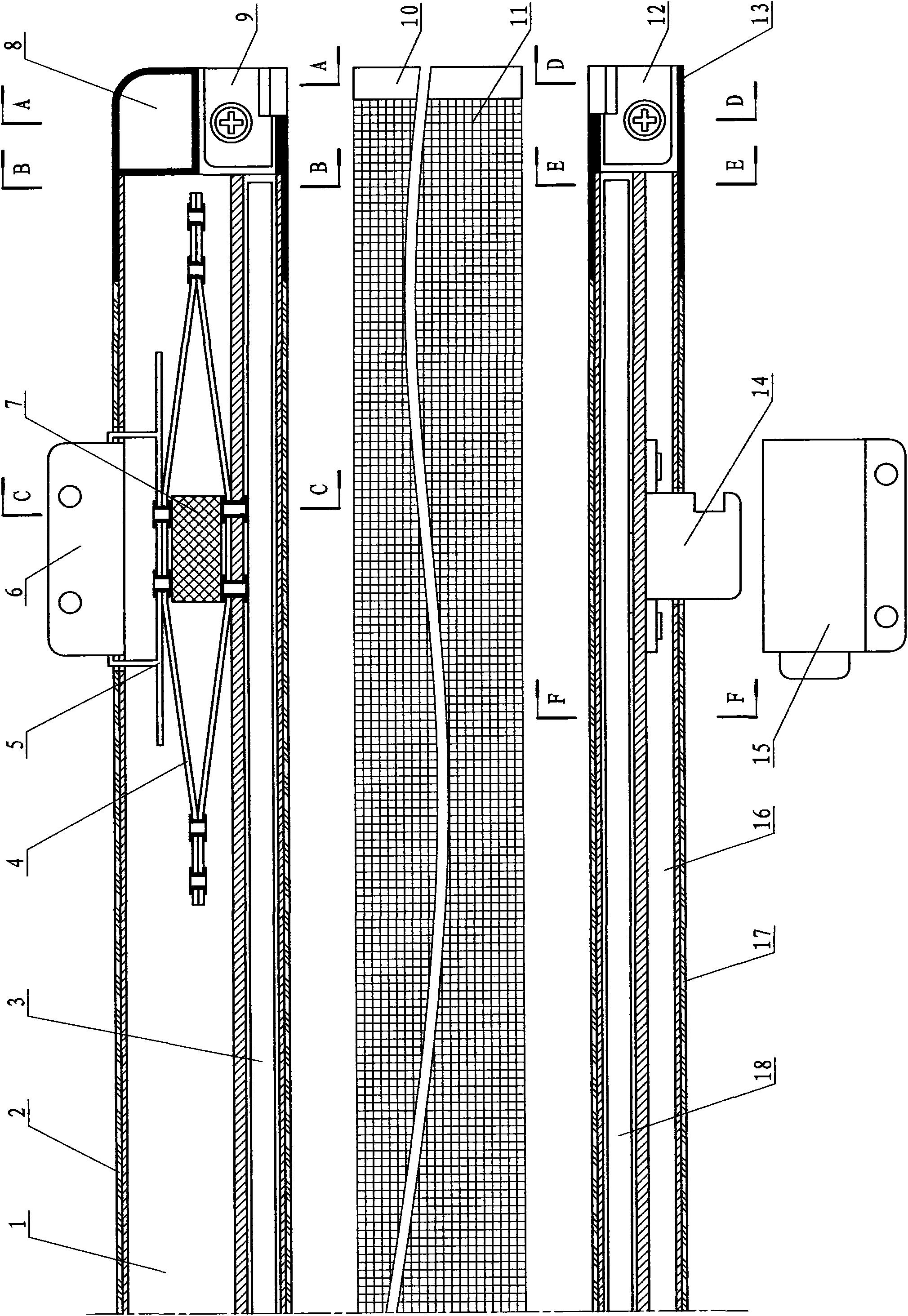

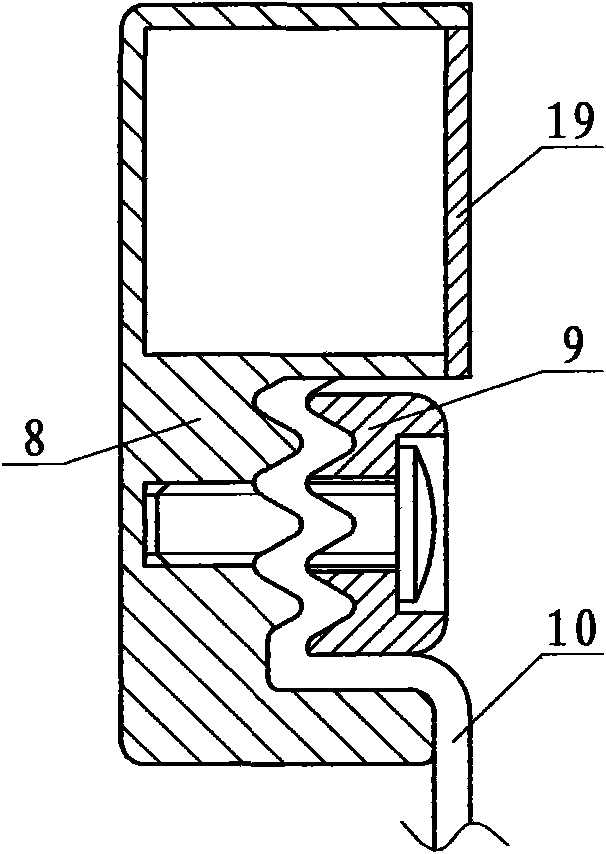

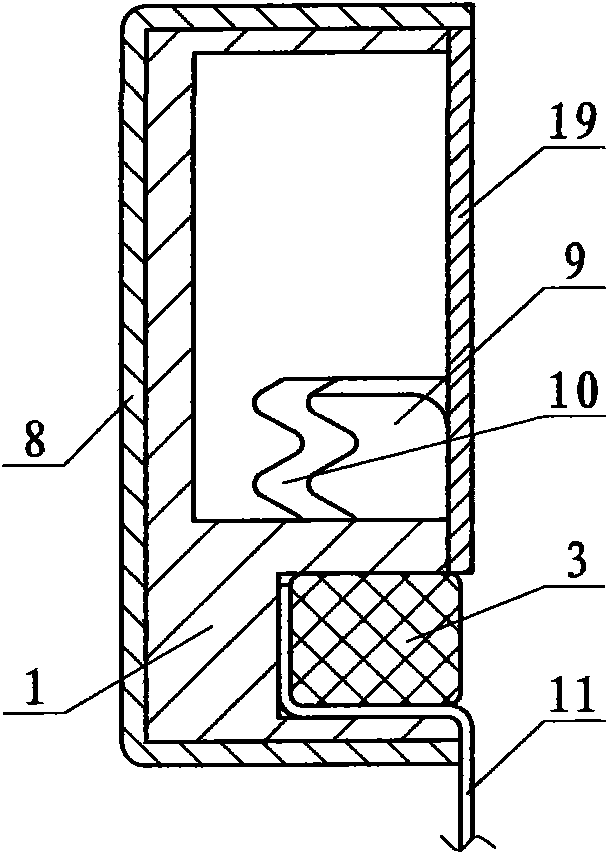

Elastic tightening type screen window

The invention relates to an elastic tightening type screen window which belongs to a building window anti-mosquito device and aims to solve the problems of incomplete function and poor comprehensive performance generally existing in the traditional screen window. The elastic tightening type screen window comprises an anti-mosquito screen, a screen window upper frame, a screen window lower frame, a screen window side frame and a connecting member, wherein the screen window side frame is a flexible frame, is provided with an elastic member in a malposition operating way, can be provided with a locking mechanism, a fine adjusting mechanism, a frame spacing member, a buffer member, and the like or not as required, generally adopts an elastic element limit design and can adopt an anti-mosquito screen coiling design as required. In a working state, the screen window side frame or the frame spacing member achieves the tightening degree of set wind resistant strength by vertical tension generated through the elastic member. The invention is suitable for an outward opening window and a sliding window of a building.

Owner:郭波

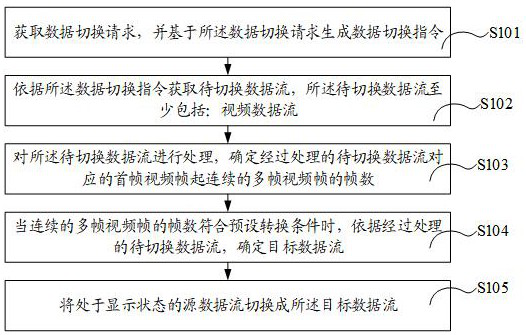

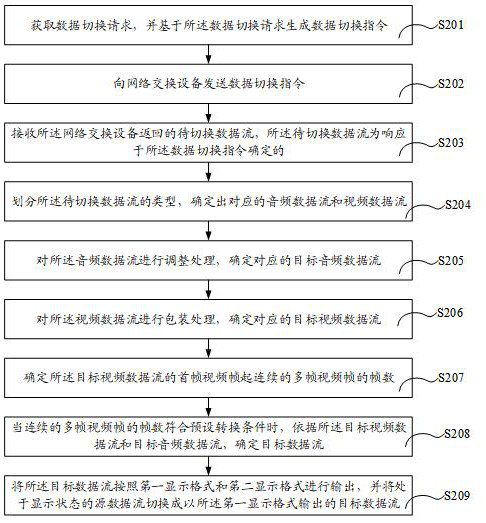

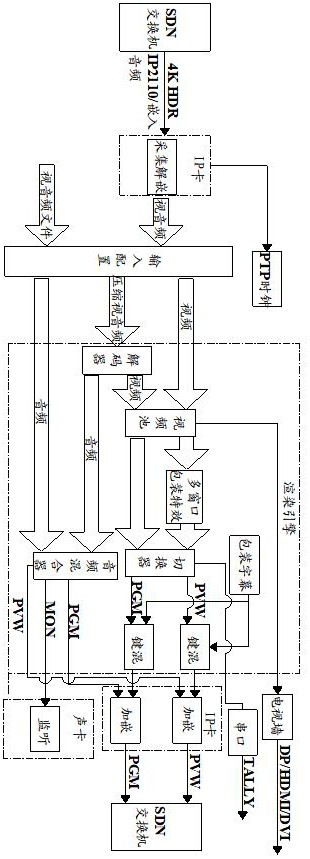

Streaming media data switching method and device, equipment and storage medium

ActiveCN114827747AMeet the needs of on-site productionTelevision system detailsColor television detailsComputer hardwareEngineering

The invention discloses a streaming media data switching method and device, equipment and a storage medium. Relates to the technical field of streaming media. The data switching method comprises the following steps: firstly, generating a data switching instruction according to an obtained data switching request, and obtaining a to-be-switched data stream according to the data switching instruction; then processing the to-be-switched data stream, determining whether the frame number of multiple continuous video frames starting from the first video frame corresponding to the processed to-be-switched data stream meets a preset conversion condition or not, determining a target data stream according to the processed to-be-switched data stream under the condition that the preset conversion condition is met, and switching the to-be-switched data stream according to the target data stream. And finally, switching the source data stream in the display state into the target data stream. Therefore, the obtained data stream can be processed in real time, and the data stream can be switched without framing, so that the on-site manufacturing requirement is met.

Owner:广州市广播电视台 +1

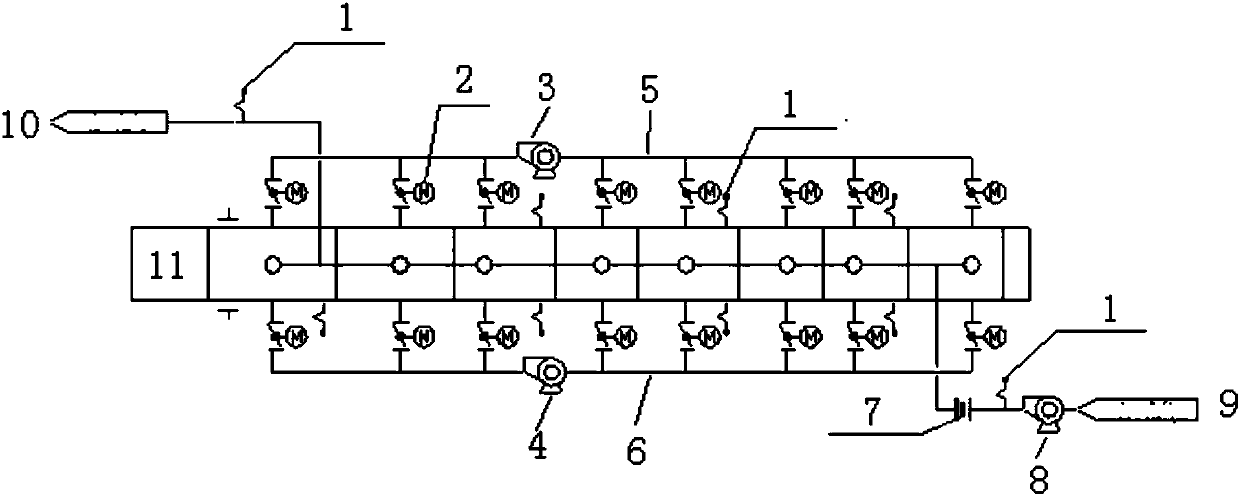

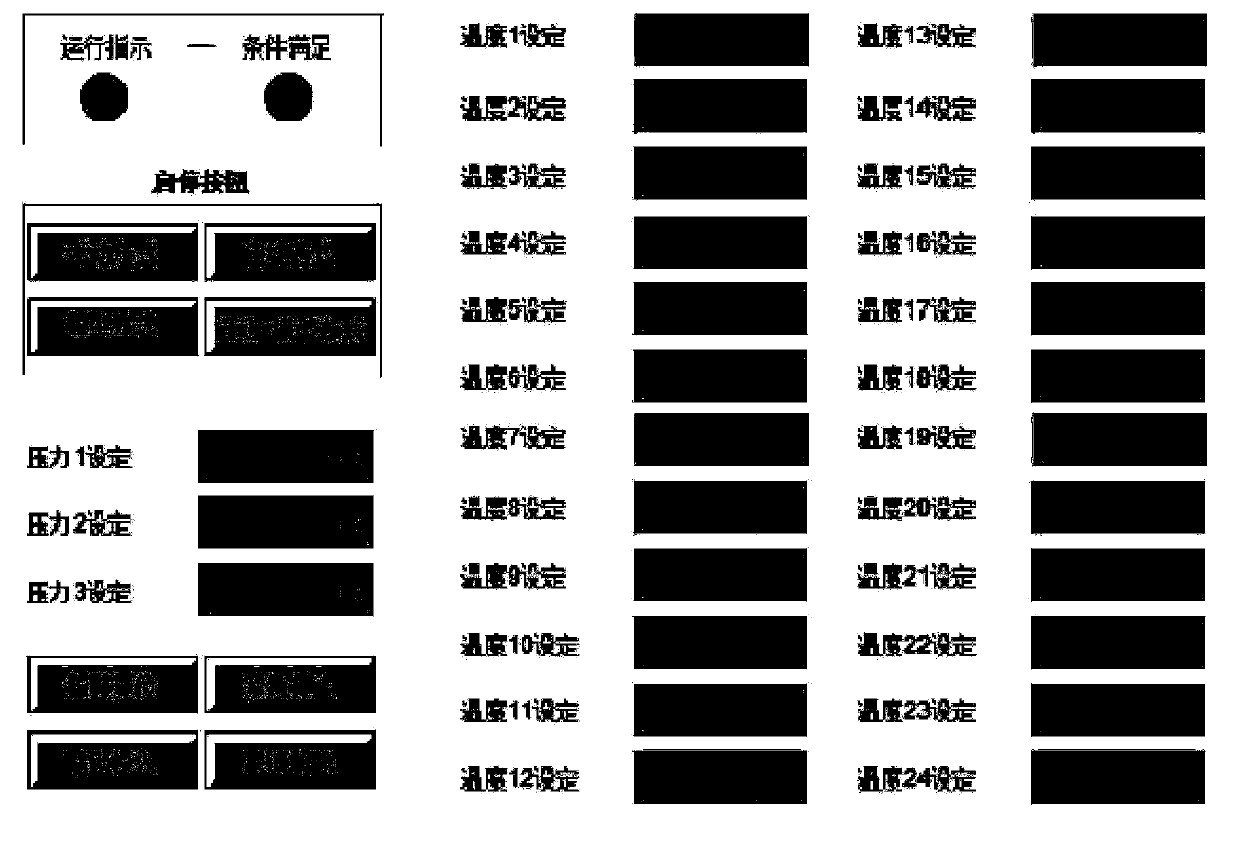

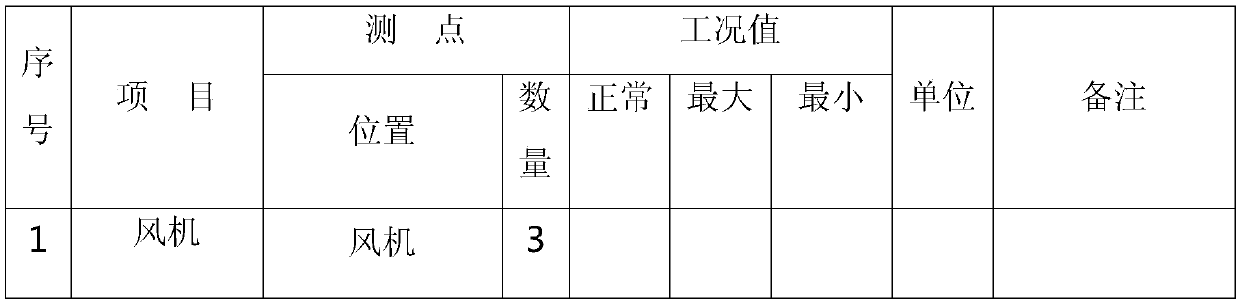

Precise temperature control system of low-temperature chain grate machine for copper tailings and control method of precise temperature control system

PendingCN107621170APrecise automatic controlSimple and fast operationFurnace typesTemperature controlAutomatic control

The invention discloses a precise temperature control system of a low-temperature chain grate machine for copper tailings and a control method of the precise temperature control system. The control system comprises a chain grate machine body, a main fan, a first circulating fan, a second circulating fan, a first main circuit and a second main circuit; the chain grate machine body is divided into 24 segments in the length direction, the first segment of the chain grate machine body is provided with a fuel gas inlet, and the 24 segment of the chain grate machine body is provided with a fuelgas outlet; the main fan is connected with the fuel gas inlet of the first segment of the chain grate machine body through a pipeline; the left side and the right side of each segment of the chain grate machine body are provided with branch circuits respectively, and each branch circuit is provided with an electric control valve; all the branch circuits on the left side of the chain grate machinebody are converged to the first main circuit, and all the branch circuits on the right side of the chain grate machine body are converged to the second main circuit; and the first circulating fan is located on the first main circuit, and the second circulating fan is located on the second main circuit. According to the precise temperature control system of the low-temperature chain grate machine for the copper tailings and the control method of the precise temperature control system, the temperature of the low-temperature chain grate machine for the copper tailings can be precisely and automatically controlled, operation is easy, convenient, reasonable, humanized, automatic and precise, the site production requirements can be completely met, manpower resources are saved, and unmanned production can be achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

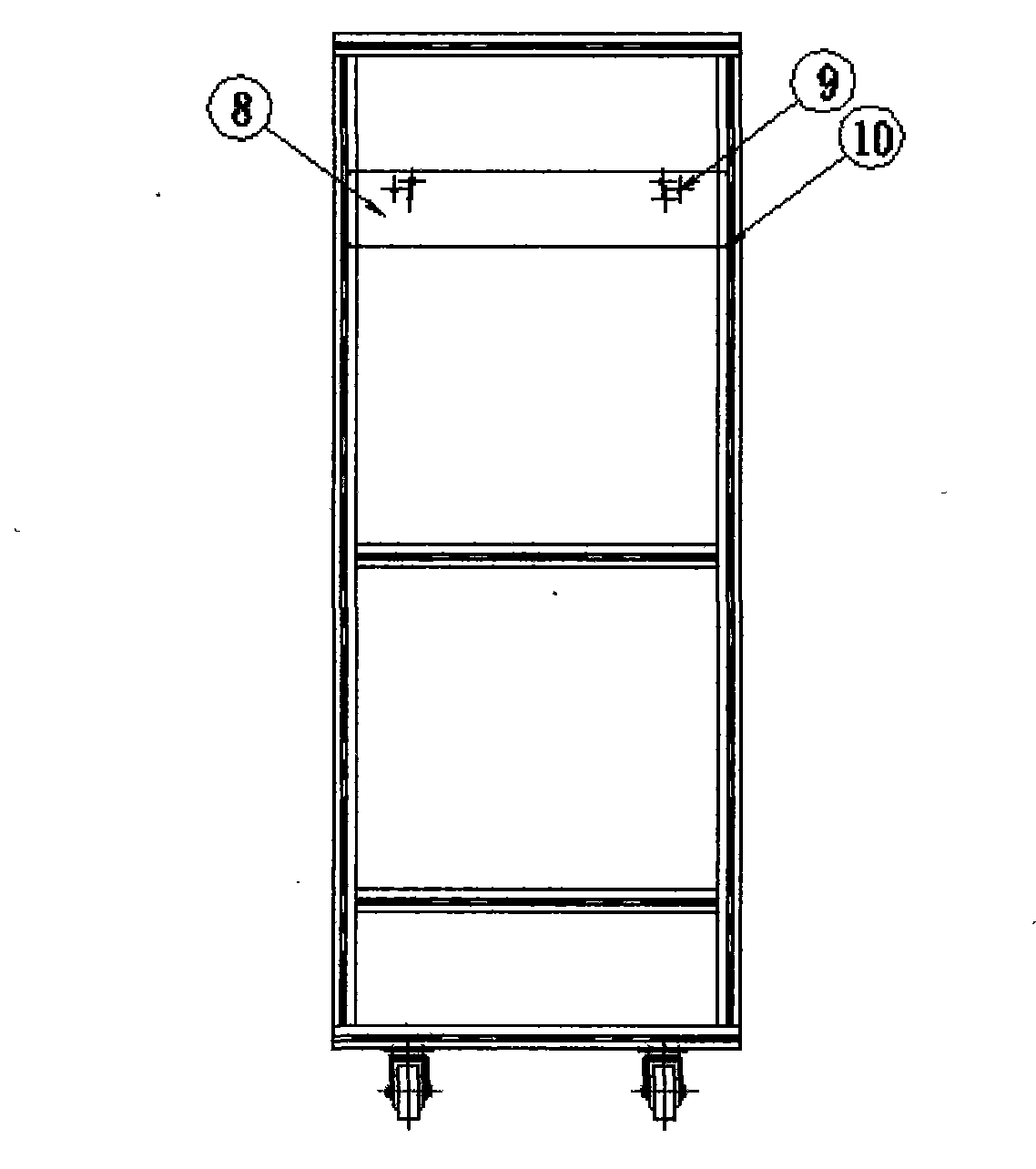

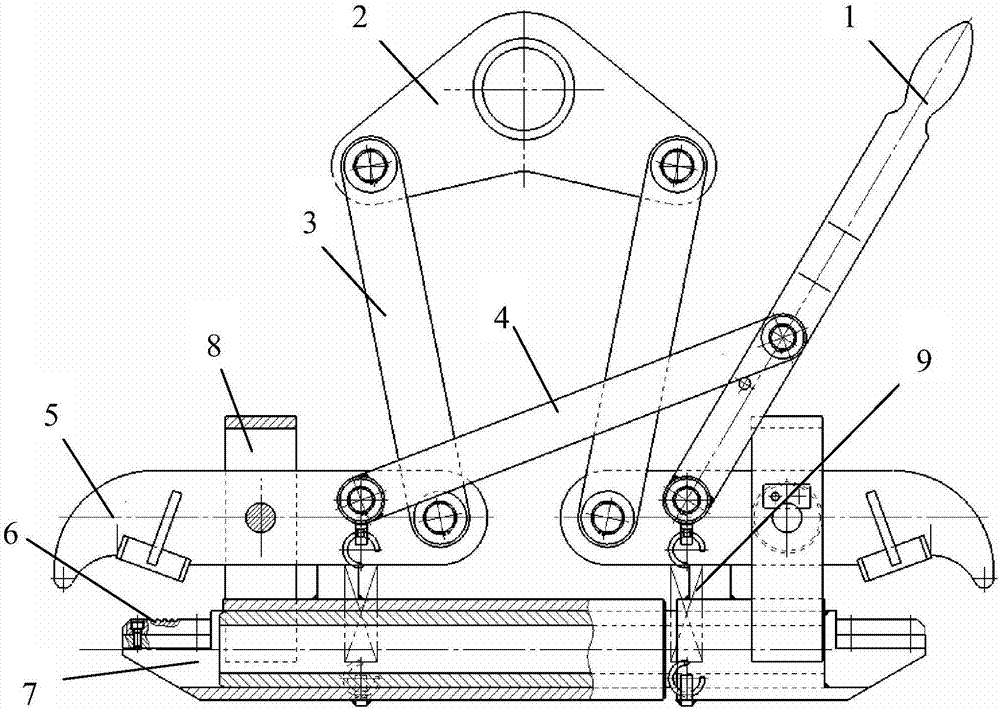

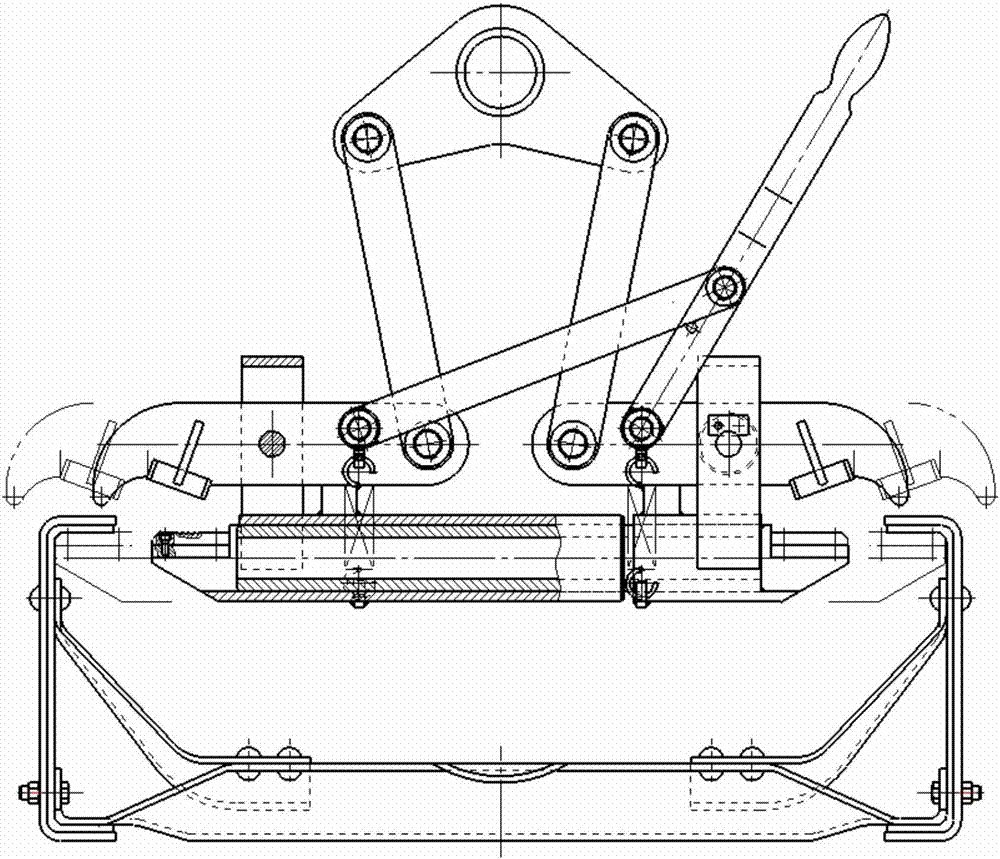

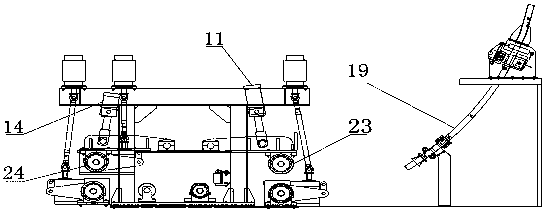

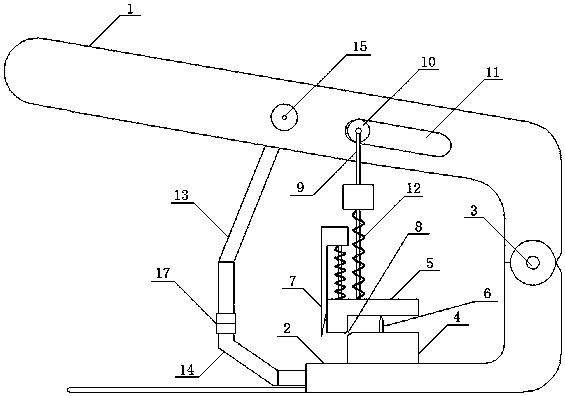

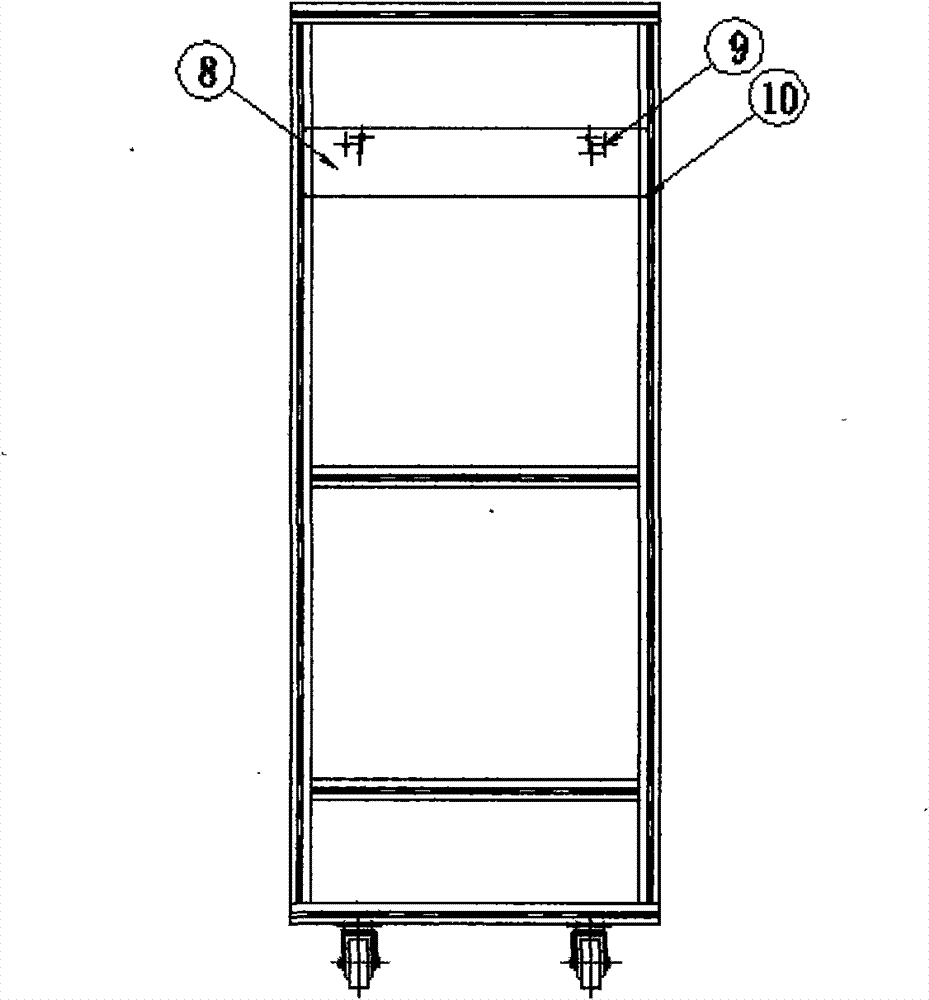

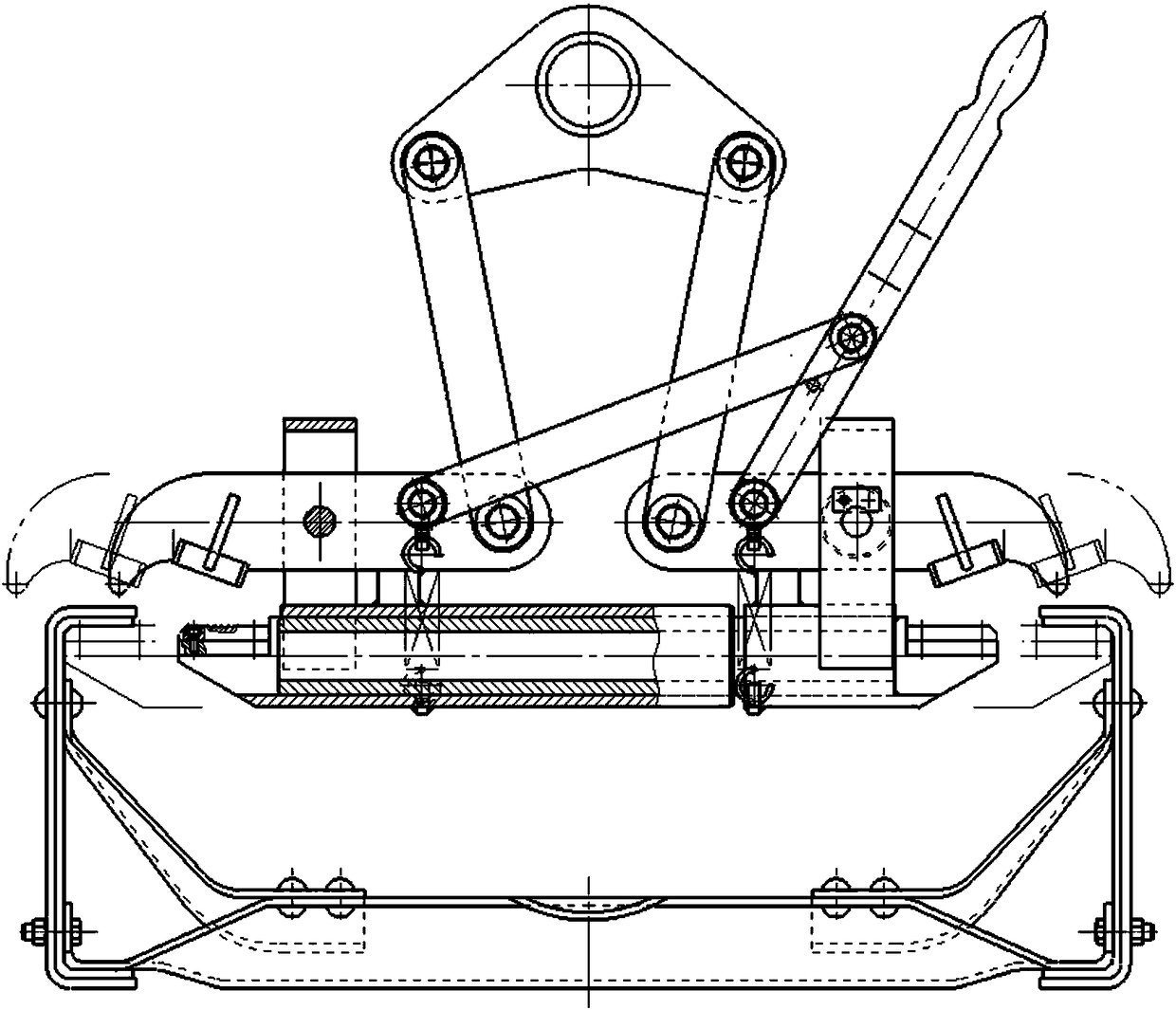

Car frame lifting appliance

ActiveCN107055313AImprove securityImprove transport efficiencyLoad-engaging elementsVehicle frameEngineering

The invention discloses a car frame lifting appliance. The car frame lifting appliance comprises an operating handle (1), a lifting lug (2), lifting rods (3), a connecting rod (4), clamping mechanisms, skid-proof blocks (6), guide bodies (7), connecting blocks (8) and springs (9), wherein the two ends of the lifting lug (2) are each rotationally connected with one end of the corresponding lifting rod (3); the other ends of the two lifting rods (3) are separately rotationally connected with the inner ends of two clamping mechanisms; the connecting blocks (8) are separately fixed to the two ends of the guide bodies (7); the middle parts of the clamping mechanisms are each rotationally connected with the corresponding connecting block (8); each guide body (7) is of a telescopic structure; the end parts of the guide bodies (7) are each fixedly provided with one skid-proof block (6); one end of the connecting rod (4) is articulated with one clamping mechanism; one end of the handle (1) is articulated with the other clamping mechanism; and the other end of the connecting rod is articulated with the handle (1). The car frame lifting appliance disclosed by the invention is applicable to car frames different in width and is safe in use and high in efficiency; and moreover, by adopting the lifting appliance, a single person can accomplish the lifting work of the car frame.

Owner:BEIBEN TRUCKS GRP

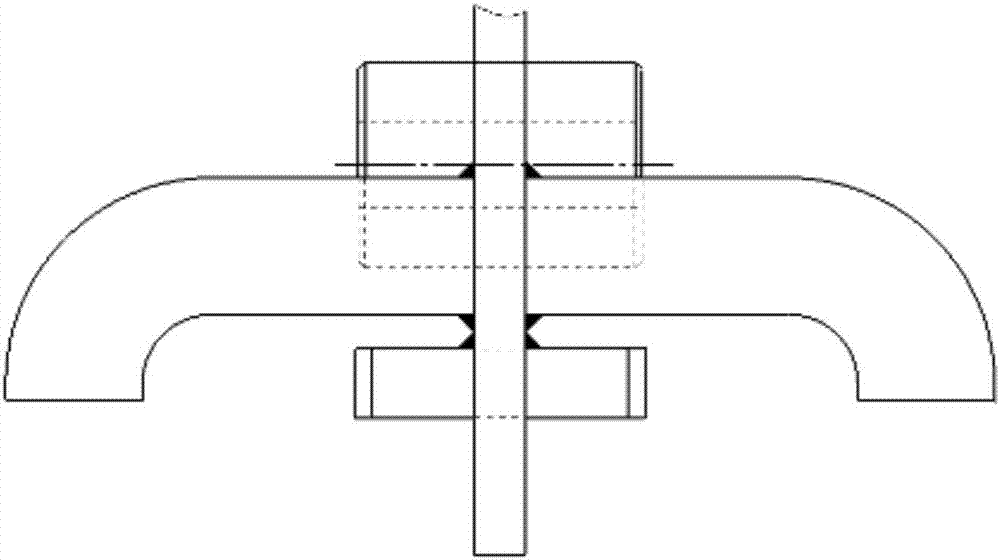

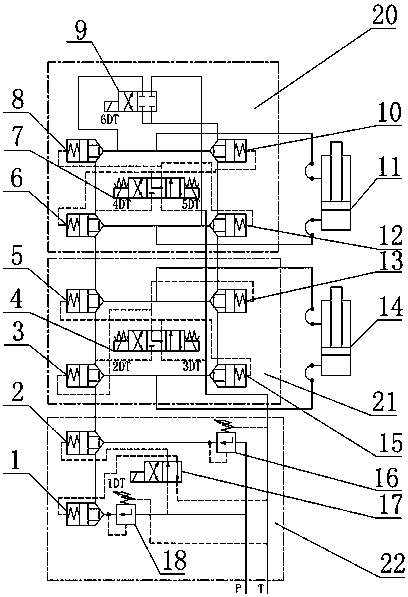

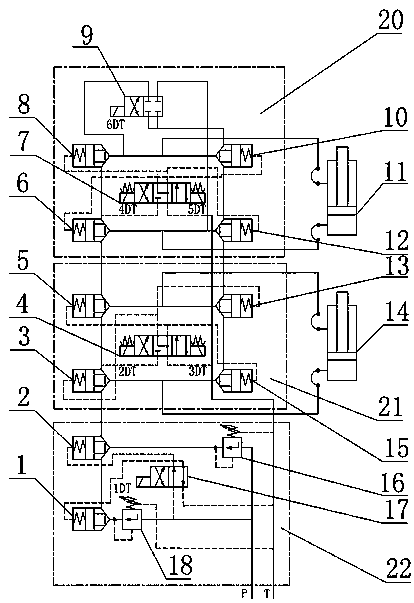

Method for achieving tension leveling hydraulic control through inserting type logical valve

ActiveCN107630852AReduce internal leakageImprove reliabilityServomotor componentsHydraulic control unitEngineering

The invention relates to a method for achieving tension leveling hydraulic control through an inserting type logical valve, and belongs to the technical field of steel making continuous casting. According to the technical scheme, a tension leveling hydraulic control function unit is composed of stacking type logical valve integration blocks, and the tension leveling hydraulic control unit of one-piece flow of a continuous casting machine is composed of a pressure reducing unit, a blank pulling unit and a blank disengaging unit. Due to the fact that basic assemblies of a cartridge valve are standard parts and a valve element of the cartridge valve is of a conical valve element structure, the cartridge valve is high in reliability, in other words, the anti-clamping capability of the cartridge valve is greatly higher than that of an ordinary sliding valve, and the self dirt removing capability is achieved. Meanwhile, the circulation capability of the cartridge valve is much higher than that of the ordinary sliding valve, and due to the fact that assemblies of the cartridge valve are inserted in the hydraulic integration blocks, the structure of a hydraulic integration system composedof the cartridge valve is greatly reduced; and a basic unit is of a conical valve structure, inner leakage is extremely small, the response performance is good, and high-speed switchover can be conducted.

Owner:河北张宣高科科技有限公司

Twisted pair cutting and threading device

ActiveCN103401128BEasy crimpingMeet the needs of on-site productionLine/current collector detailsEngineeringTweezers

The invention relates to a cutting and stroking device for a twisted pair. The cutting and stroking device comprises a pedestal, a compression bar, a stroking and cutting device and a cable fixing device. The cutting and stroking device is characterized in that the compression bar is connected with the pedestal through a hinge, and the stroking and cutting device and the cable fixing device are arranged between the compression bar and the pedestal. According to the cutting and stroking device for the twisted pair, two operation links including stroking and cutting can be finished once, the stroking effect is good, and a cable is connected with an RJ45 joint in a compression manner conveniently in the next step; the cutting and stroking device further has the characteristics of simple structure, low manufacturing cost, simplicity and convenience in use and operation and convenience in carrying and can completely meet field fabrication requirements of a twisted pair joint.

Owner:STATE GRID CORP OF CHINA +2

Production process of special straightening roll for imported two-roll straightening machine

InactiveCN106994584AHigh surface hardnessImprove wear resistanceMetal-working apparatusFurnace typesFree coolingSlow cooling

The invention discloses a production process of a special straightening roll for an imported two-roll straightening machine. The production process comprises the following steps: step 1: adopting Cr12MoV as a material of the straightening roll, and performing a blank precision casting process and a slow cooling process, wherein degree of finish of the surface of a precision casting mould is 25-30 [mu]s; step 2: performing forging on the blank with a forging ratio of 3-4; heating the forged blank to a temperature of 1200-1250 DEG C within 4-6 hours, preserving the heat for 12-48 hours, discharging the blank, and performing forging and preliminary forming at a temperature of 1100-1200 DEG C; step 3: performing softening annealing treatment on forged and formed blank, and ensuring the outline dimension to reach the approximate dimension of a curve of the straightening roll; and step 4: performing thermal treatment on the processed straightening roll: performing vacuum quenching on the straightening roll, naturally cooling in a sealed space until the indoor temperature is reached.

Owner:NANJING IRON & STEEL CO LTD

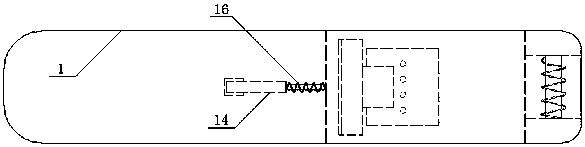

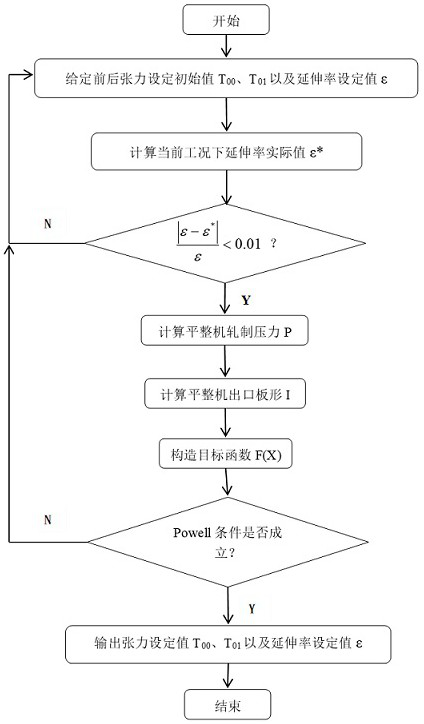

Tension and elongation optimization method for single-stand temper mill unit

ActiveCN113042571AMeet the needs of on-site productionTension/compression control deviceProfile control deviceThermodynamicsMechanical engineering

The invention relates to a tension and elongation optimization method for a single-stand temper mill unit, and belongs to the technical field of cold rolling. According to the technical scheme, production parameters of the single-rack temper mill unit are summarized, and the optimal front-back tension distribution state of the unit is calculated by integrating multiple factors; the outlet strip shape and a slip factor are taken as target functions, and the actual elongation and the set elongation are controlled within a certain range as constraint conditions; and initial front and back tension and elongation are set, production parameters meeting strip shape control and rolling stability are obtained through multiple iterations, and meanwhile the requirements of two important indexes are met. The method has the beneficial effects that the method has important guiding significance on field production, and compared with a conventional manual adjustment and plate shape feedback adjustment method, the tension calculation and setting method is closer to reality and better meets the requirements of field production, and the plate shape can be further improved.

Owner:TANGSHAN IRON & STEEL GROUP +2

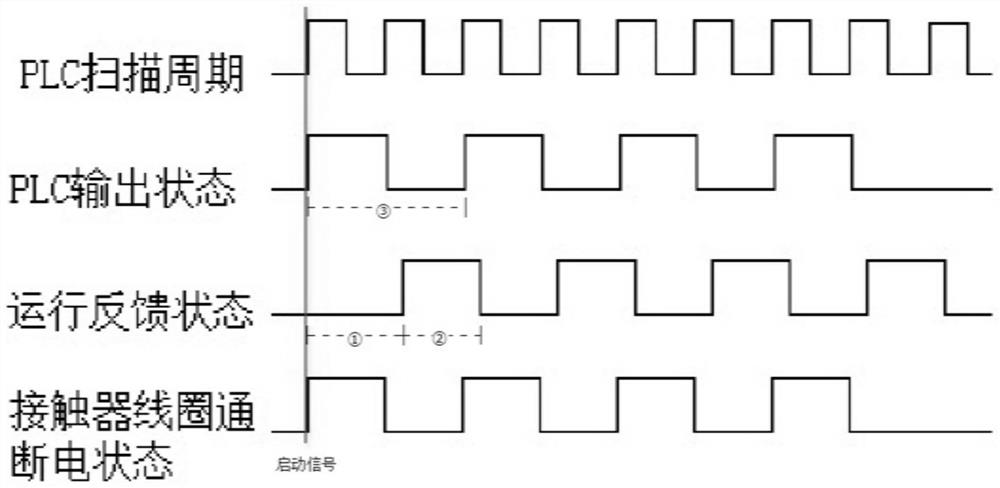

Omnibearing analyzing and solving method for jump problem of contactor

ActiveCN113238521AEliminate jumpingJumping avoidanceTotal factory controlProgramme control in sequence/logic controllersTime delaysElectric machine

The invention provides a method for comprehensively analyzing and solving the jump problem of a contactor. The method specifically comprises the following steps: S1, changing a coil type motor starting control command in an original PLC program into an RS trigger while adding a counting function when motor operation feedback is 1, and when motor operation feedback signals are continuously overturned, setting output to be 0, so that a contactor is released and is not attracted any more; and S2, replacing a starting intermediate relay with a time delay relay, and replacing an original normally open contact with a time delay normally open contact, wherein a contact for feeding back the operation of the motor to the PLC is changed from a normally open contact for starting the intermediate relay to an auxiliary normally open contact of the main contactor, so that the jumping phenomenon caused by the fact that the PLC cannot confirm the actual state of the field due to the fault of the relay or the action time difference between the relay and the main contactor can be effectively avoided. The method has the beneficial effects that the contactor jumping phenomenon caused by voltage fluctuation and software and hardware faults in PLC control is thoroughly eliminated.

Owner:ANGANG STEEL CO LTD

A Method of Using Cartridge Logic Valve to Realize Hydraulic Control of Pulling and Straightening

ActiveCN107630852BReduce internal leakageImprove reliabilityServomotor componentsHydraulic control unitContinuous casting

The invention relates to a method for achieving tension leveling hydraulic control through an inserting type logical valve, and belongs to the technical field of steel making continuous casting. According to the technical scheme, a tension leveling hydraulic control function unit is composed of stacking type logical valve integration blocks, and the tension leveling hydraulic control unit of one-piece flow of a continuous casting machine is composed of a pressure reducing unit, a blank pulling unit and a blank disengaging unit. Due to the fact that basic assemblies of a cartridge valve are standard parts and a valve element of the cartridge valve is of a conical valve element structure, the cartridge valve is high in reliability, in other words, the anti-clamping capability of the cartridge valve is greatly higher than that of an ordinary sliding valve, and the self dirt removing capability is achieved. Meanwhile, the circulation capability of the cartridge valve is much higher than that of the ordinary sliding valve, and due to the fact that assemblies of the cartridge valve are inserted in the hydraulic integration blocks, the structure of a hydraulic integration system composedof the cartridge valve is greatly reduced; and a basic unit is of a conical valve structure, inner leakage is extremely small, the response performance is good, and high-speed switchover can be conducted.

Owner:河北张宣高科科技有限公司

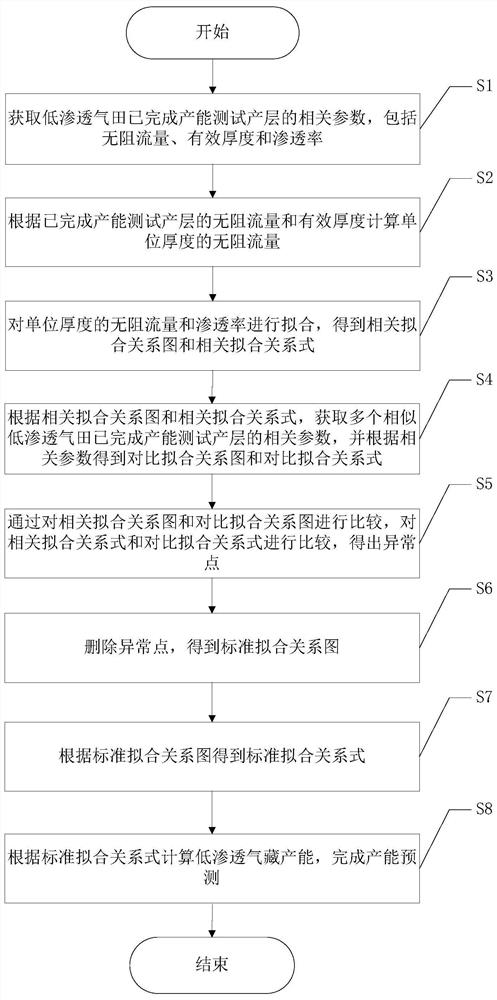

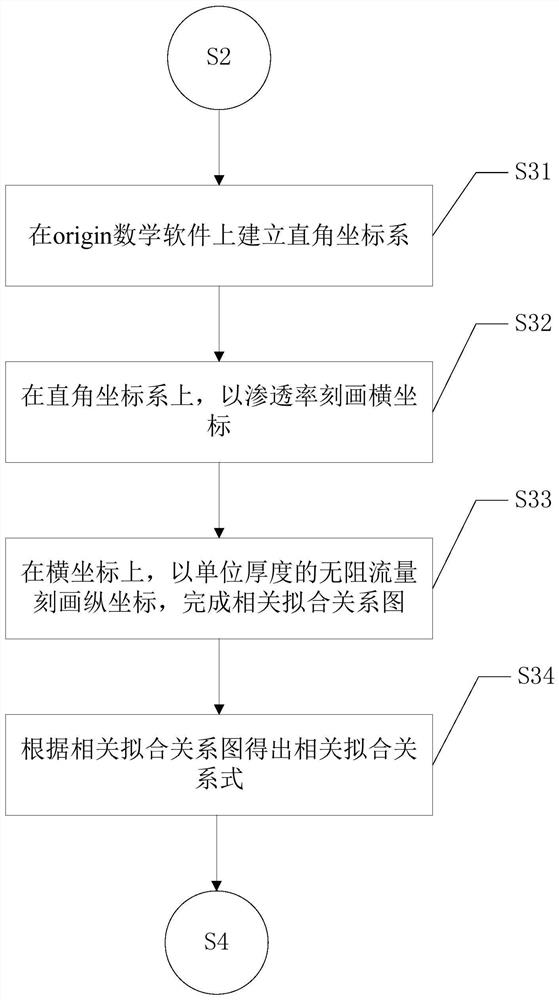

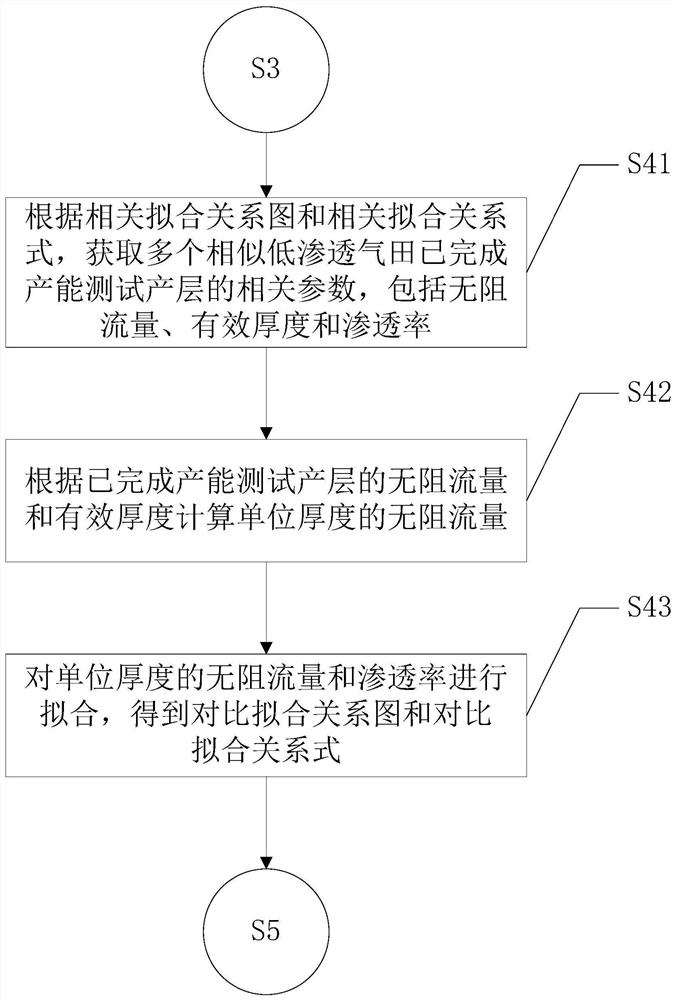

A Rapid Productivity Prediction Method for Low Permeability Gas Reservoirs

ActiveCN110782100BQuick forecastHigh predictive applicabilityForecastingThermodynamicsStatistical physics

The invention discloses a method for quickly predicting the production capacity of low-permeability gas reservoirs, which includes obtaining relevant parameters of production layers that have been tested for production capacity, analyzing and obtaining a correlation fitting relationship diagram and a correlation fitting relationship formula; and then combining multiple similar low-permeability gas fields The production capacity prediction data is obtained from the comparison and fitting relationship diagram and the comparison and fitting relationship formula; finally, the abnormal points are deleted, and the standard fitting relationship diagram is obtained to obtain the standard fitting relationship formula, and the production capacity prediction is completed. The method for quickly predicting the production capacity of low-permeability gas reservoirs of the present invention combines the production test data of domestic similar typical low-permeability gas fields, returns a large number of statistical samples, obtains a fitting relational expression, and completes the rapid production capacity prediction. The method has high predictive applicability, fast speed and high result accuracy, and can meet the needs of on-site production.

Owner:SOUTHWEST PETROLEUM UNIV

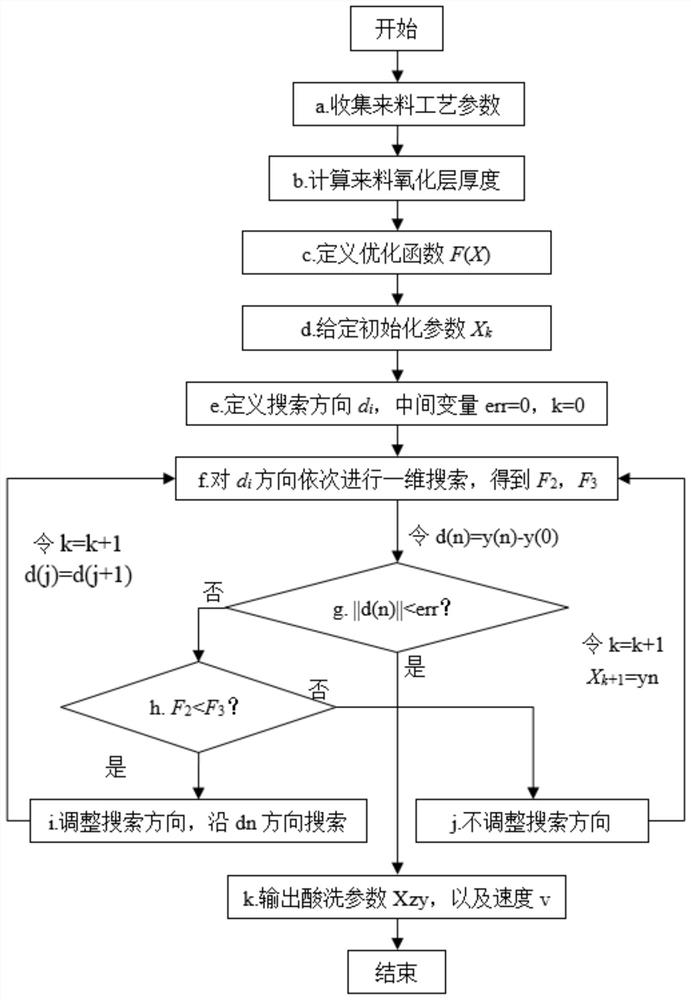

Strip steel cold rolling pickling parameter optimization method

PendingCN114792051ABest pickling speedMeet the needs of on-site productionDesign optimisation/simulationSpecial data processing applicationsProcess engineeringStrip steel

The invention provides a strip steel cold rolling pickling parameter optimization method, and relates to the field of cold rolling. The strip steel cold rolling pickling parameter optimization method comprises the following steps executed by a computer: (a) collecting incoming material process parameters; (b) calculating the thickness h of an oxide layer of the supplied material; (c) defining an optimization function F (X) = f (h, X); (d) giving an initialization parameter X; (e) defining a search direction; (f) sequentially performing one-dimensional search on the search direction; (g) checking whether a termination condition is satisfied; (h) determining a search direction; (i) adjusting a search direction; (j) not adjusting the search direction; and (k) finally outputting an optimal pickling speed v meeting constraint conditions and a corresponding pickling process parameter combination Xzy at the moment, and completing optimization of the parameter model. By summarizing production parameters of the cold rolling pickling unit, the optimal pickling speed of the unit is calculated by integrating pickling influence parameters in multiple aspects, and the production efficiency is further improved.

Owner:唐山扬邦钢铁技术研究院有限公司 +1

Method and tool for installing large electric vertical-type rectangular cabinet products

ActiveCN101668414BMeet the needs of on-site productionReduce labor intensitySubstation/switching arrangement casingsElectrical componentsEngineeringElectrical and Electronics engineering

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

A frame hanger

ActiveCN107055313BImprove securityImprove transport efficiencyLoad-engaging elementsVehicle frameEngineering

The invention discloses a car frame lifting appliance. The car frame lifting appliance comprises an operating handle (1), a lifting lug (2), lifting rods (3), a connecting rod (4), clamping mechanisms, skid-proof blocks (6), guide bodies (7), connecting blocks (8) and springs (9), wherein the two ends of the lifting lug (2) are each rotationally connected with one end of the corresponding lifting rod (3); the other ends of the two lifting rods (3) are separately rotationally connected with the inner ends of two clamping mechanisms; the connecting blocks (8) are separately fixed to the two ends of the guide bodies (7); the middle parts of the clamping mechanisms are each rotationally connected with the corresponding connecting block (8); each guide body (7) is of a telescopic structure; the end parts of the guide bodies (7) are each fixedly provided with one skid-proof block (6); one end of the connecting rod (4) is articulated with one clamping mechanism; one end of the handle (1) is articulated with the other clamping mechanism; and the other end of the connecting rod is articulated with the handle (1). The car frame lifting appliance disclosed by the invention is applicable to car frames different in width and is safe in use and high in efficiency; and moreover, by adopting the lifting appliance, a single person can accomplish the lifting work of the car frame.

Owner:BEIBEN TRUCKS GRP

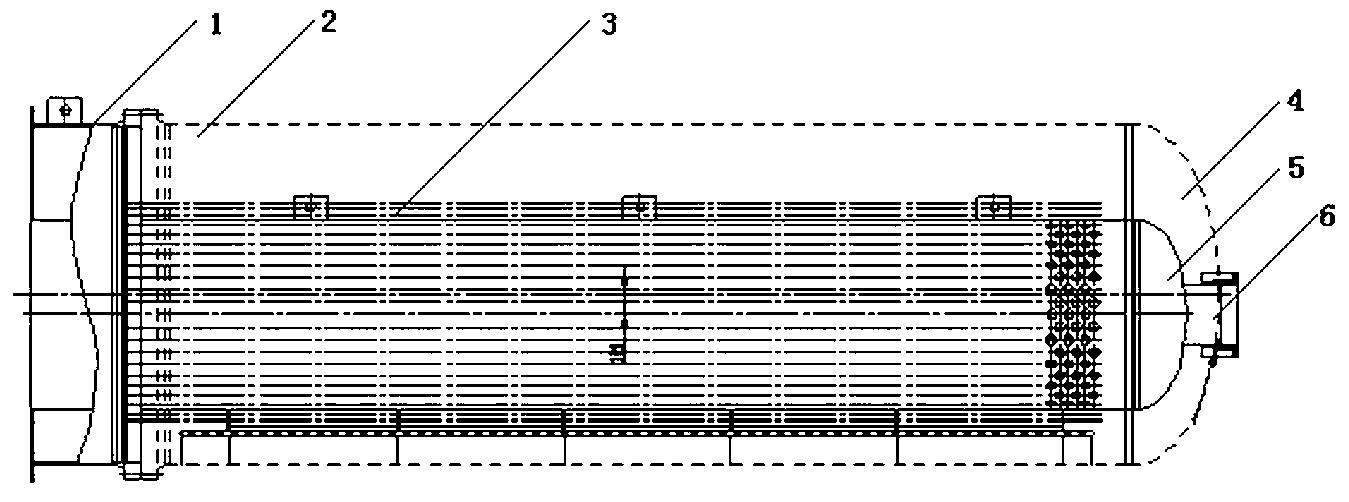

Extractable fire cylinder smoke tube

InactiveCN103307618AQuick disassembly and replacementSimple structureChimneysEngineeringHeating furnace

The invention provides an extractable fire cylinder smoke tube which comprises a fire cylinder smoke box, a vessel flange, a sliding channel, a tube body rear sealed end, a fire cylinder smoke tube body and an explosion door, wherein a heating furnace body adopts a dual-return travel structure; the fire cylinder smoke tube body and the fire cylinder smoke box are connected via the vessel flange with an equipment cylinder to form a whole; a support is arranged at the bottom of the fire cylinder smoke box; the sliding channel is arranged in the cylinder body of the fire cylinder smoke box; a lifting lug capable of lifting is arranged at the upper part of the fire cylinder smoke box; the cylinder rear sealed end is located at the rear part of the fire cylinder smoke box; both the explosion door and the cylinder rear sealed end adopt a packing box type structure; the fire cylinder smoke tube is simple and reasonable in structure, safe and convenient to use and convenient to maintain, can be dismounted and replaced by applying a gantry and a lifting hoist on application site rapidly, can quickly recover production, and satisfies demand for field production.

Owner:SHANDONG JUNMA GASOLINEEUM EQUIP MFG GROUP

An ultrasonic stress detection device with adjustable sound beam angle and test area

ActiveCN105300578BAchieving Residual Stress TestingReduce manufacturing costForce measurementBeam angleHeat-affected zone

An ultrasonic stress detection device capable of adjusting the sound beam angle and the test area, comprising: a central positioning platform (100); parallel rail frames (200) are fixed on opposite sides of the center positioning table (100); each parallel rail frame (200 ) are slidingly connected to the glass base (300), the upper part of the glass base (300) is a U-shaped groove track (310) with a convex arc guide surface (311), and the probe fixing wedge (400) and the U-shaped groove track The side wall of (310) is slidingly connected, and the concave arc surface of the probe fixing wedge (400) cooperates with the convex arc guide surface (311) of the U-shaped groove rail (310); the upper part of the probe fixing wedge (400) is set There is a probe fixing cavity (500) for fixing the ultrasound probe. The equipment can realize the adjustment and correction of the first critical angle of the weld seam and the heat-affected zone, and the residual stress test of different materials; and the equipment can realize the residual stress test in different areas of the workpiece to be tested.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com