On-line intelligent detection device and method for particle size of sintering fuel

An intelligent detection and fuel technology, which is applied in the direction of measuring devices, particle size analysis, and material analysis, can solve problems such as poor air permeability of the sintered material layer, take away, and inconsistent particle size distribution results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0174] According to the second embodiment of the present invention, an online intelligent detection method for sintered fuel particle size is provided:

[0175] An online intelligent detection method for sintered fuel particle size or a method using the above-mentioned online intelligent detection device for sintered fuel particle size, the method includes the following steps:

[0176]1) The intelligent robot 14 transports the discharged charging container 4 to the first weighing device 2 for weighing, and obtains the weight (m0) of the unloaded charging container 4;

[0177] 2) The intelligent robot 14 transports the charging container 4 to the feeding station T0, and the manipulator (or automatic sampler) grabs the sample of the fuel to be tested from the fuel transport belt, and the grabbed fuel sample falls through the feeding bin 13 In the charging container 4;

[0178] 3) The intelligent robot 14 transports the charging container 4 to the first weighing device 2 for wei...

Embodiment 1

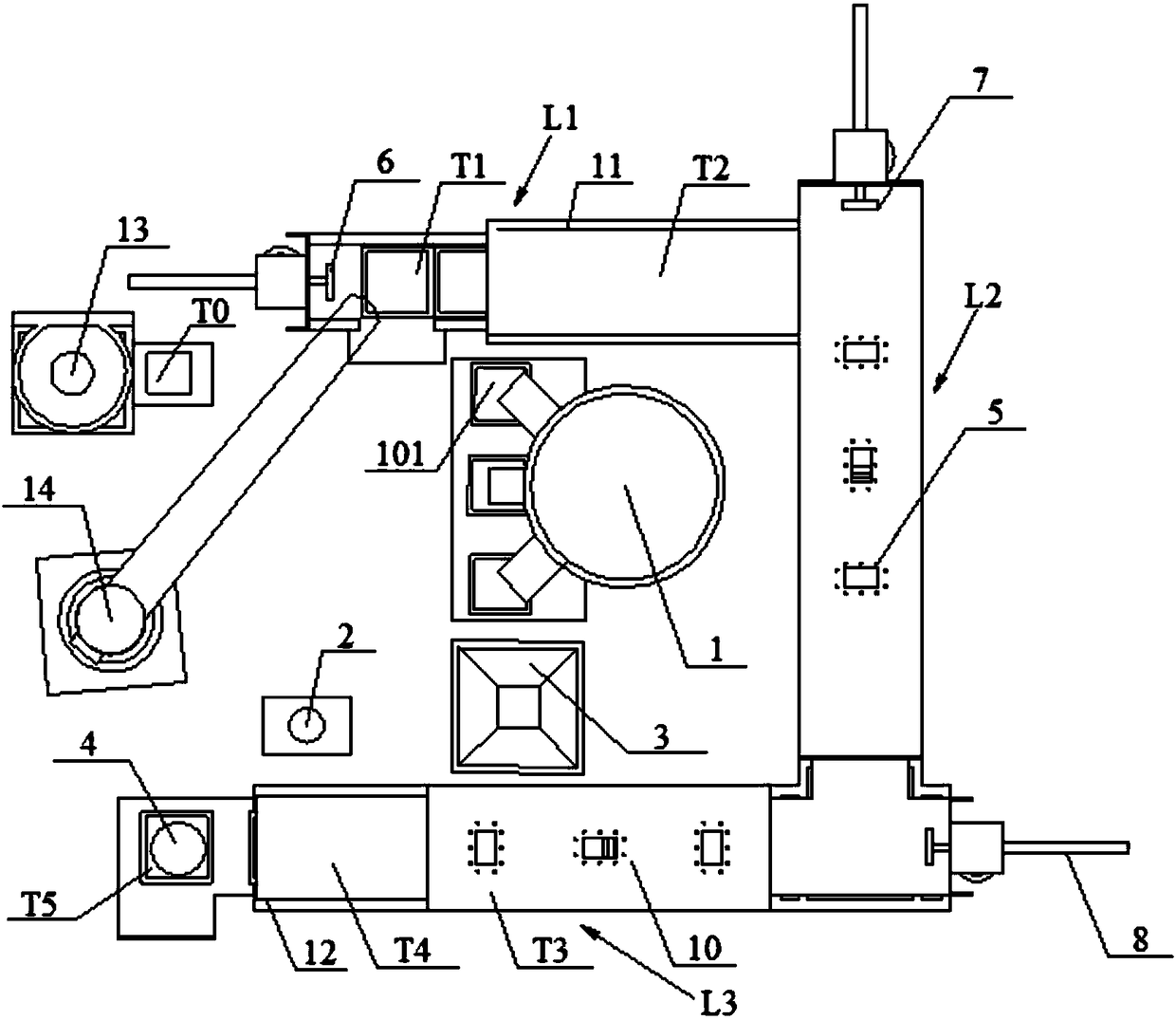

[0268] Such as figure 1, an online intelligent detection device for sintered fuel particle size, the device includes: 3 slides connected in sequence, a powerful vibrating screen 1, a first weighing device 2 and a discharge bin 3 arranged on the side of the slides, and also includes Feed station T0. Among them, the three slideways are the first slideway L1, the second slideway L2 and the third slideway L3. One end of the second slideway L2 is connected to the first slideway L1 and the other end is connected to the third slideway L3. 6 charging containers 4 are placed on each slideway. The first slideway L1 is divided into a first area T1 and a second area T2 as a first microwave suppression station, and the second area T2 communicates with the second slideway L2. The second slideway L2 is a microwave drying area, and three first microwave sources 5 are arranged on the top of the second slideway L2. The third slideway L3 is divided into a third area T3 as a microwave drying j...

Embodiment 2

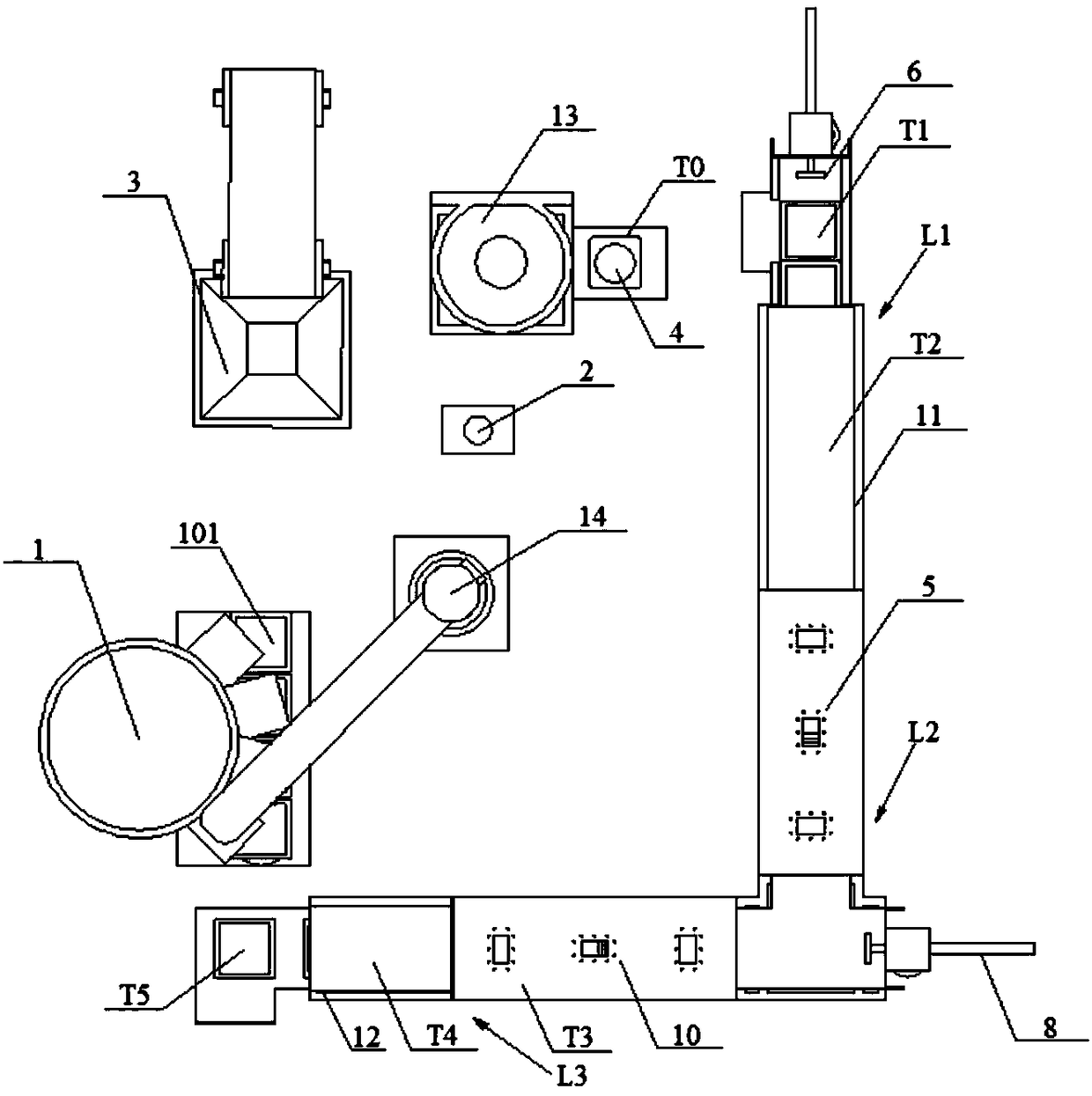

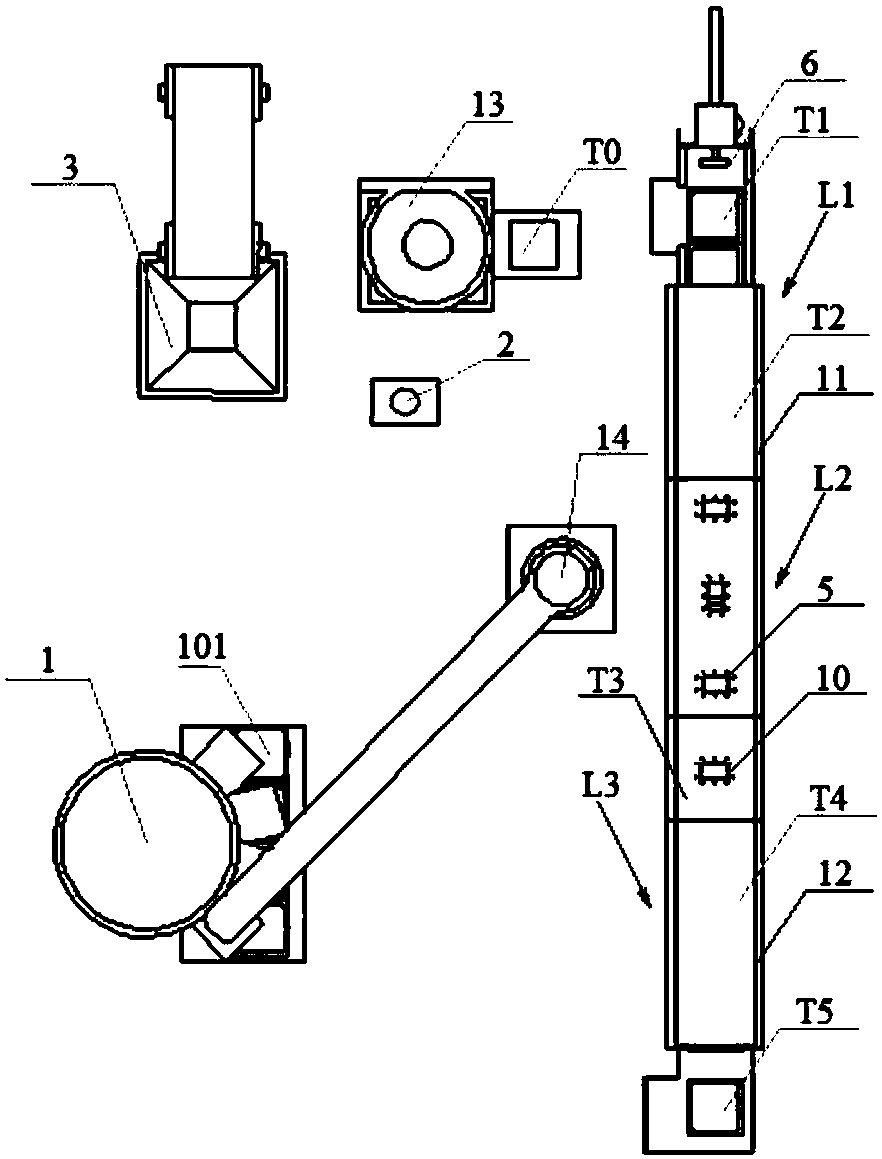

[0274] Such as figure 2 , an online intelligent detection device for sintered fuel particle size, the device includes: 3 slides connected in sequence, a powerful vibrating screen 1, a first weighing device 2 and a discharge bin 3 arranged on the side of the slides, and also includes Feed station T0. Among them, the three slideways are the first slideway L1, the second slideway L2 and the third slideway L3. One end of the second slideway L2 is connected to the first slideway L1 and the other end is connected to the third slideway L3. 6 charging containers 4 are placed on each slideway. The first slideway L1 is divided into a first area T1 and a second area T2 as a first microwave suppression station, and the second area T2 communicates with the second slideway L2. The second slideway L2 is a microwave drying area, and three first microwave sources 5 are arranged on the top of the second slideway L2. The third slideway L3 is divided into a third area T3 as a microwave drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com