Oil draining device for tubing

A technology for oil drainage and tubing, which is used in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc. Discharge and other problems to achieve the effect of improving wellhead operating conditions, reducing operating costs and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

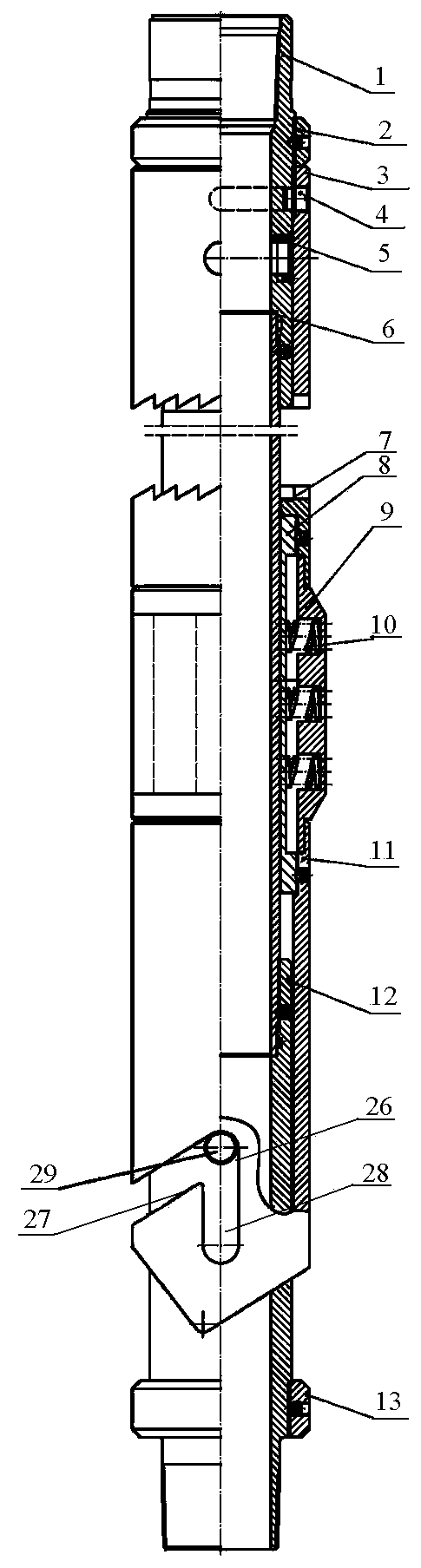

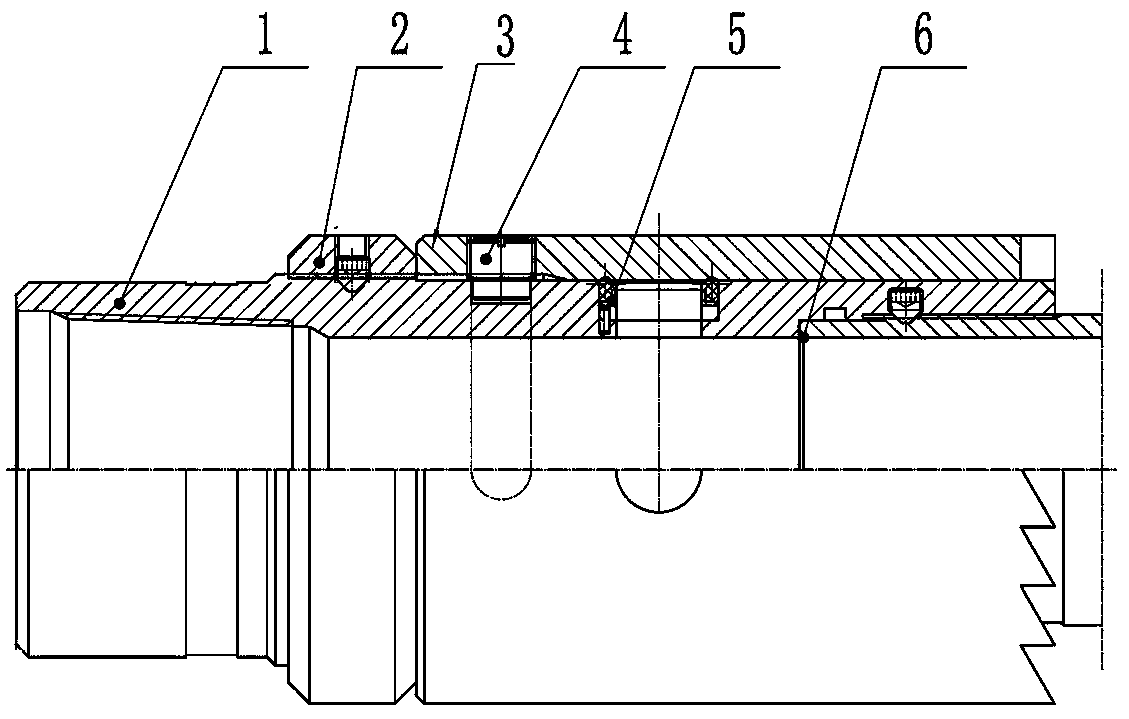

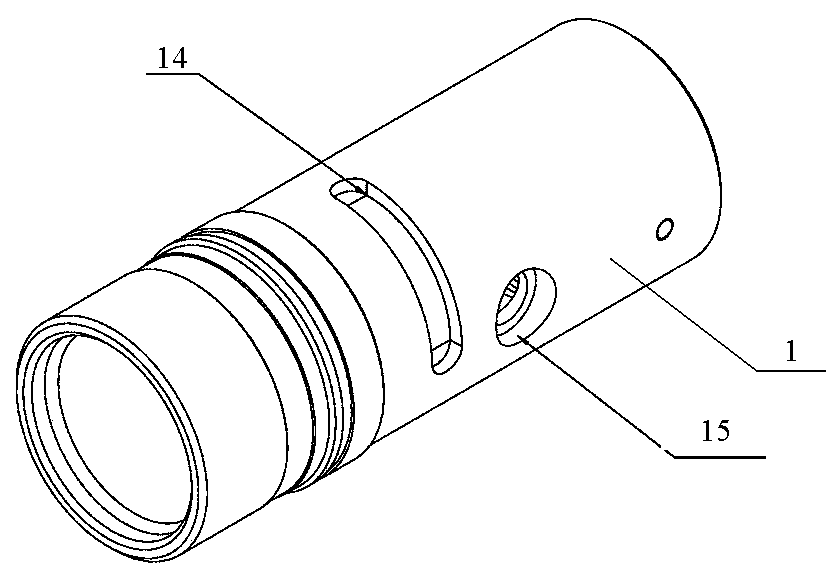

[0018] See Figure 1-Figure 7 , the specific structure of this embodiment is: a kind of tubing oil drainage device, comprising a central pipe 6, the upper end of the central pipe 6 is threaded to the upper joint 1, the lower end of the central pipe 6 is threaded to the lower joint 12, and the upper joint 1 There is a circumferential bar-shaped hole groove 14 and an oil drain hole I15, the oil drain hole I15 is provided with a sealing ring 5; the upper joint 1 is threadedly connected with a protective ring 2, and the upper joint 1 is set with a seal sleeve 3, the sealing sleeve 3 is located behind the protection ring 2, the sealing sleeve 3 is provided with a toothed rear end 16, the sealing sleeve 3 is provided with a pin hole 17 and an oil drain hole II 18, and the pin hole 17 A positioning pin 4 is provided, and the positioning pin 4 is threaded into the sealing sleeve 3, and the cylindrical shaft part of the lower part of the positioning pin 4 enters the strip-shaped hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com