An ultrasonic stress detection device with adjustable sound beam angle and test area

A test area and stress detection technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of non-perpendicular direction, large test error, inconsistent position, etc., to improve work efficiency, reduce production cost and processing cycle, improve The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

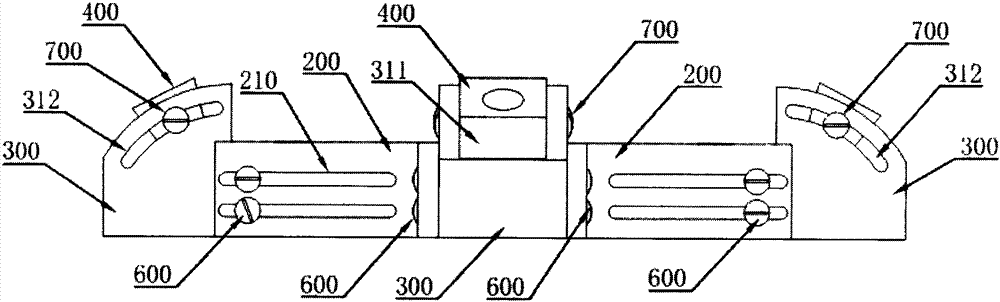

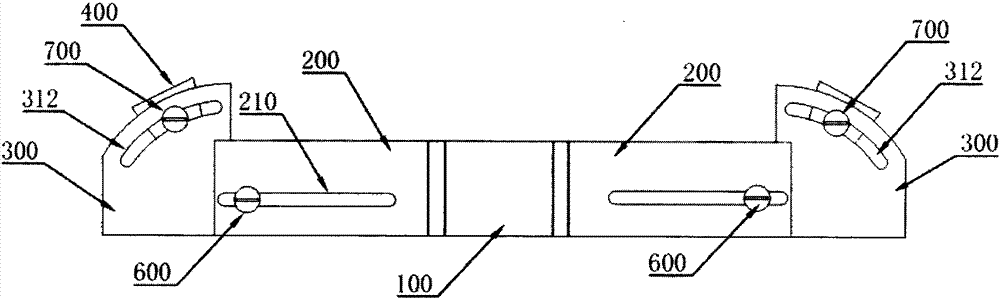

[0039] figure 1 , figure 2It is shown that a specific embodiment of the present invention is an ultrasonic stress detection device with adjustable sound beam angle and test area, including: a central positioning platform 100; parallel guide rail frames are fixed on the opposite sides of the central positioning platform 100 200, a pair of parallel rail frames 200 fixed on the opposite sides of the central positioning platform 100 are on the same axis; each of the parallel rail frames 200 is slidably connected to a glass base 300, and the upper part of the glass base 300 has a convex circle The U-shaped groove rail 310 of the arc guide surface 311, the probe fixing wedge 400 is slidably connected with the side wall of the U-shaped groove rail 310, and the concave arc surface of the probe fixing wedge 400 is connected with the convex circle of the U-shaped groove rail 310 The arc guide rail surface 311 cooperates; the probe fixing wedge 400 is provided with a probe fixing cavit...

Embodiment 2

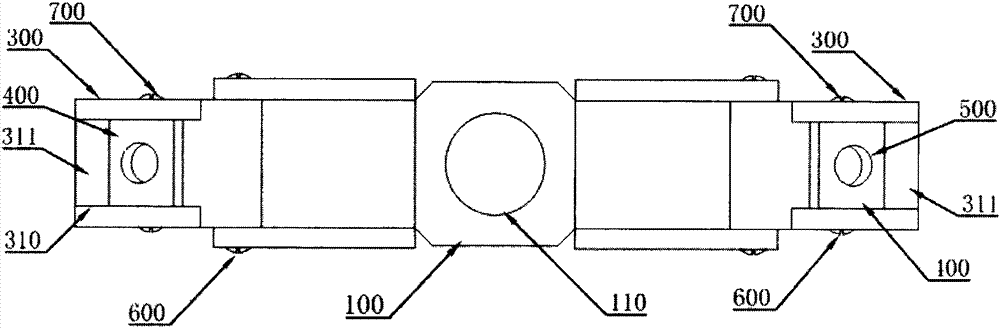

[0047] image 3 , Figure 4 It is shown that another specific embodiment of the present invention is an ultrasonic stress detection device that can adjust the beam angle and the test area, including: a central positioning platform 100; parallel guide rails are fixed on the opposite sides of the central positioning platform 100 Frame 200, a pair of parallel rail frames 200 fixed on the opposite sides of the central positioning platform 100 are on the same axis; each parallel rail frame 200 is slidably connected with a glass base 300, and the upper part of the glass base 300 has a convex The U-shaped groove rail 310 of the arc guide rail surface 311, the probe fixing wedge 400 is slidably connected with the side wall of the U-shaped groove rail 310, and the concave arc surface of the probe fixing wedge 400 is connected with the convex surface of the U-shaped groove rail 310. The arc guide rail surface 311 cooperates; the probe fixing wedge 400 is provided with a probe fixing ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com