Precise temperature control system of low-temperature chain grate machine for copper tailings and control method of precise temperature control system

A control system and a technology for a chain grate machine, applied in the field of temperature control of the chain grate machine, can solve the problems of not completely improving productivity, not realizing automation, etc., and achieving the effects of easy operation, saving human resources, and realizing unmanned production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

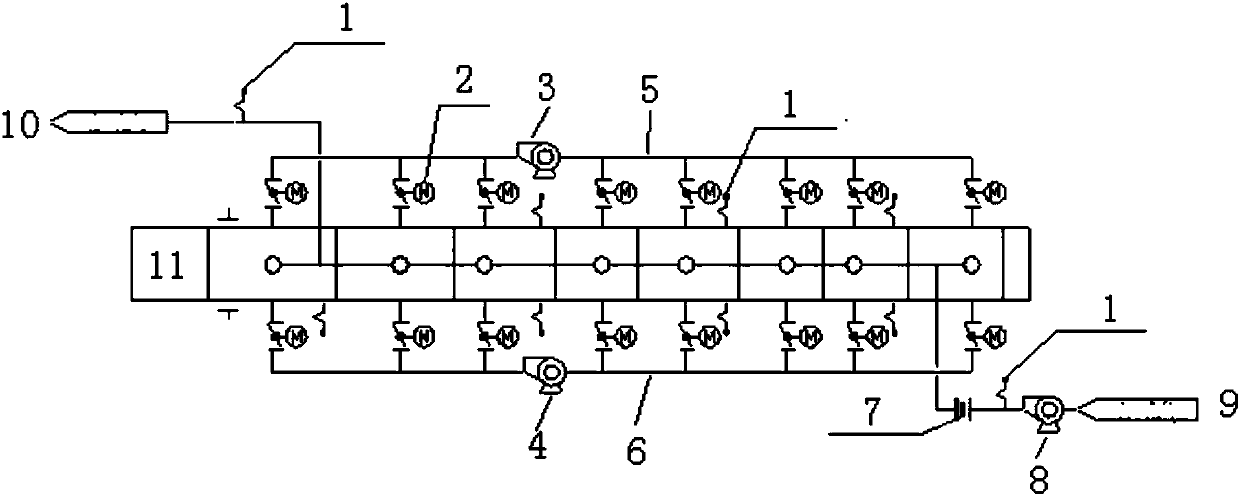

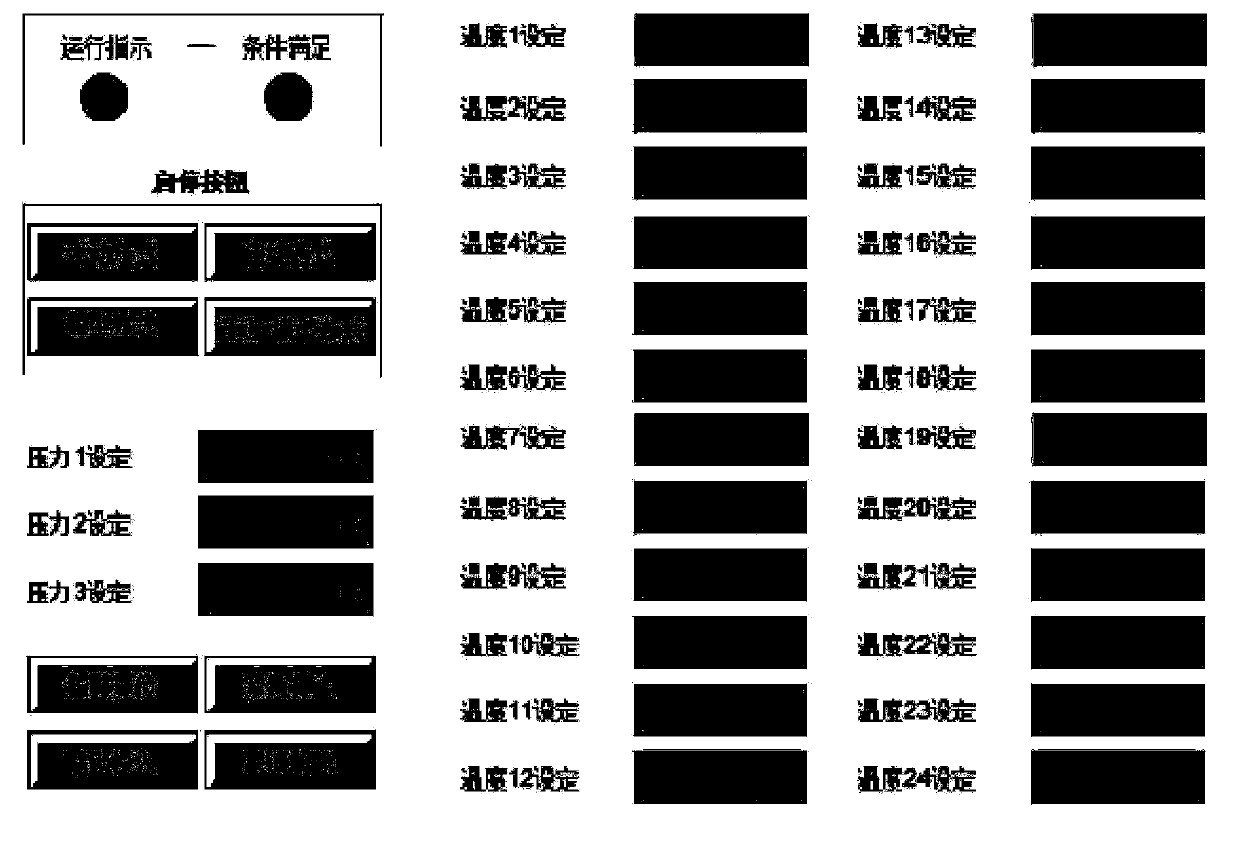

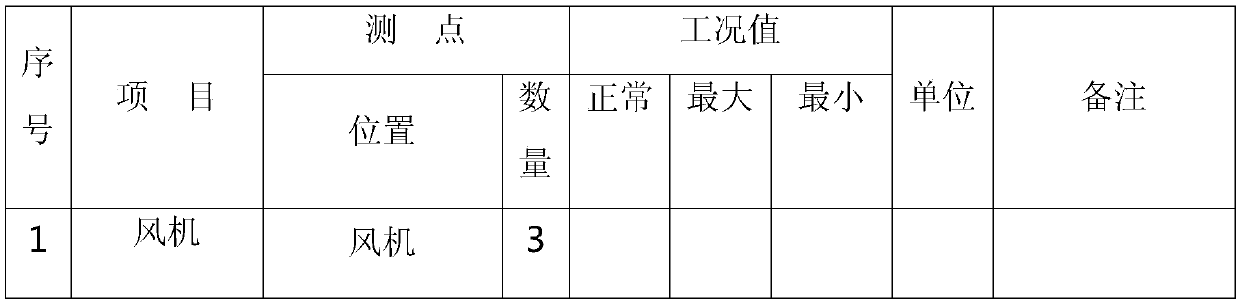

[0027] Such as figure 1 The copper tailings low-temperature grate 11 temperature precision control system shown includes the grate 11, the main fan 8, the first circulation fan 3, the second circulation fan 4, the first main road 5 and the second main road 6; The chain grate 11 is divided into 24 sections in the length direction. The first section of the chain grate 11 is provided with a smoke inlet 9, and the 24th section is provided with a smoke outlet 10. The main fan 8 is connected to the chain grate 11 through the pipeline. The flue gas inlet 9 of the first section is connected; the left and right sides of each section of the chain grate 11 are respectively provided with a branch, and each branch is provided with an electric regulating valve 2; all branches on the left side of the chain grate 11 are Converging on the first main road 5, all branches on the right side of the grate machine 11 are converging on the second main road 6; the first circulating fan 3 is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com