Automatic electroplating production line for circuit boards

A technology for electroplating production lines and circuit boards, which is applied in the electrolytic process and electrolytic components, etc., can solve the problems affecting the processing of circuit boards, the personal safety hazards of processing operators, and the poor quality of electroplating, so as to improve the overall quality and improve the corrosion resistance. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

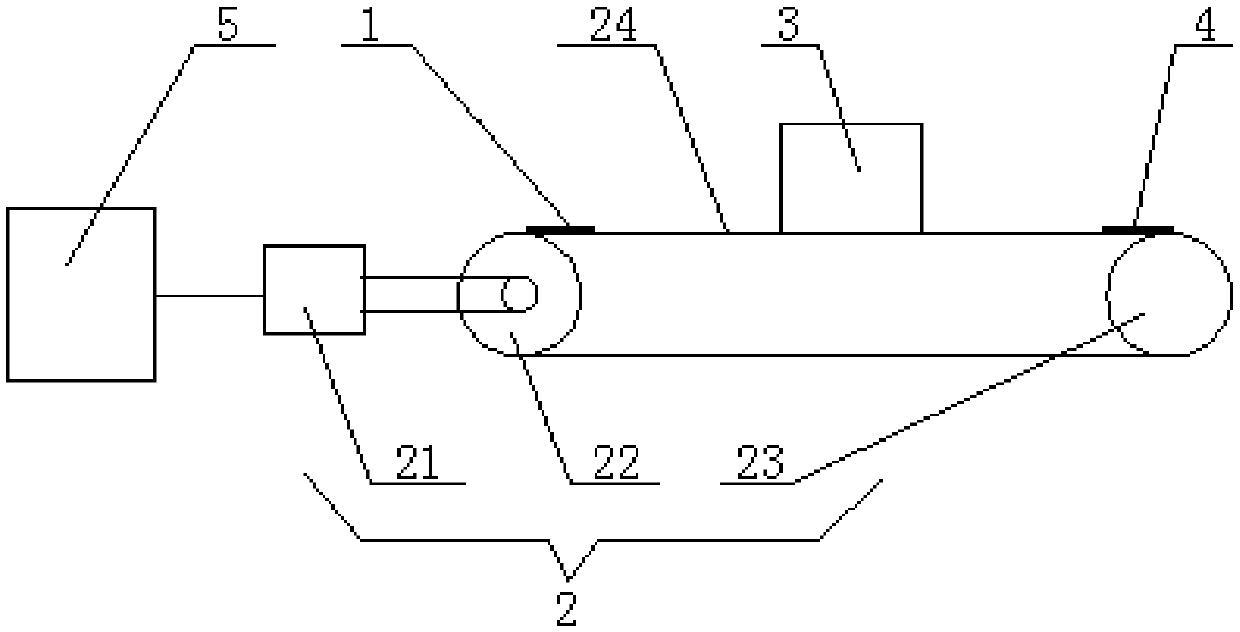

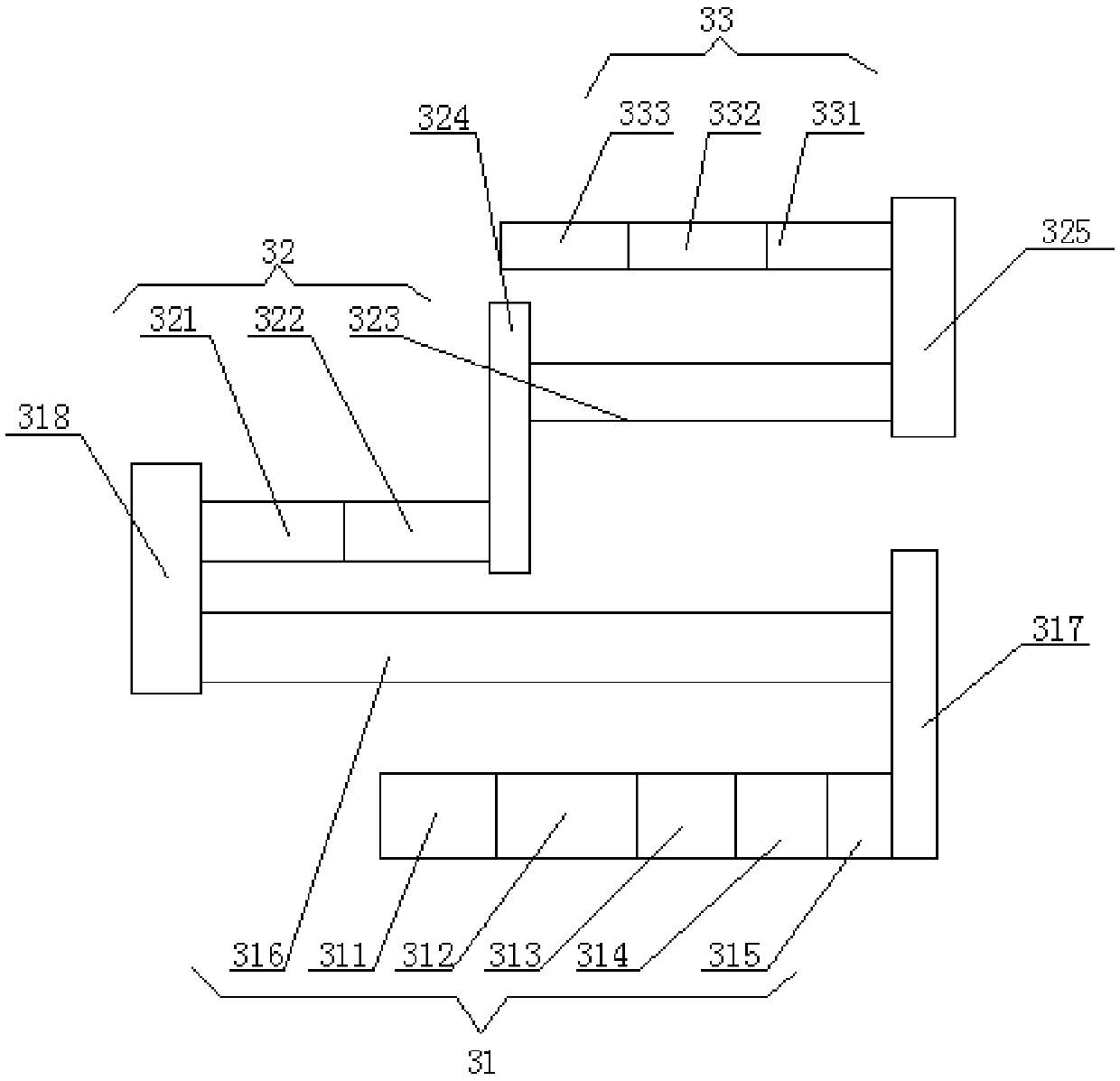

[0022] Such as Figure 1-2 As shown, one embodiment of the present invention discloses an automatic electroplating production line for circuit boards, comprising a feed area 1, a conveying mechanism 2, an electroplating mechanism 3, a discharge area 4 and an electrical control system 5; the feed area 1 and The discharge area 4 is respectively located on both sides of the transmission mechanism 2; the transmission mechanism 2 includes a driving motor 21, a driving wheel 22, and a driven wheel 23; the driving motor 21 drives the driving wheel 22 to rotate; The driving wheel 22 and the driven wheel 23 are provided with a conveyor belt 24 surrounding the driving wheel 22 and the driven wheel 23; the electroplating mechanism 3 is arranged between the feeding area 1 and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com