Rack plating production line and rack plating production process

A production process and production line technology, which is applied to the rack plating production line and the production process field to achieve the effects of improving production efficiency, simplifying the structure of the conveying device, and uniform surface color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0070] see Figure 4 , the second embodiment of the present invention provides a rack plating production process, the rack plating production process is carried out using the continuous production line provided in the first embodiment of the present invention, please refer to the first embodiment of the present invention for the following structure identification Example attached Figure 1-3C , which includes the following steps:

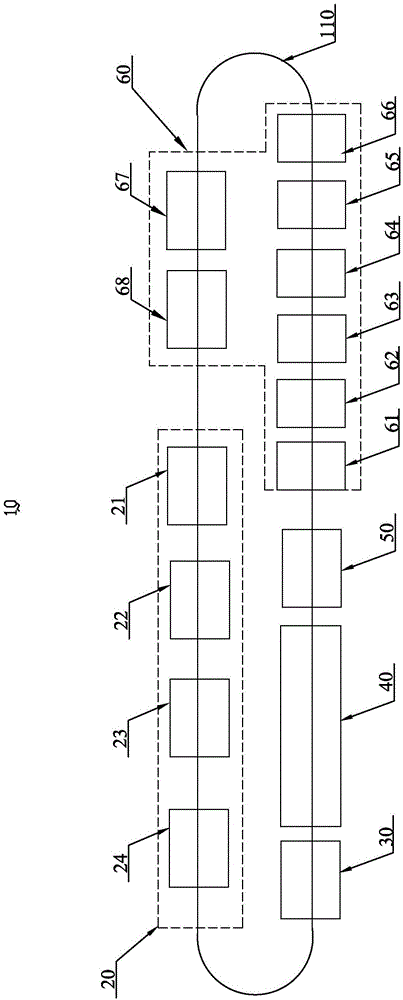

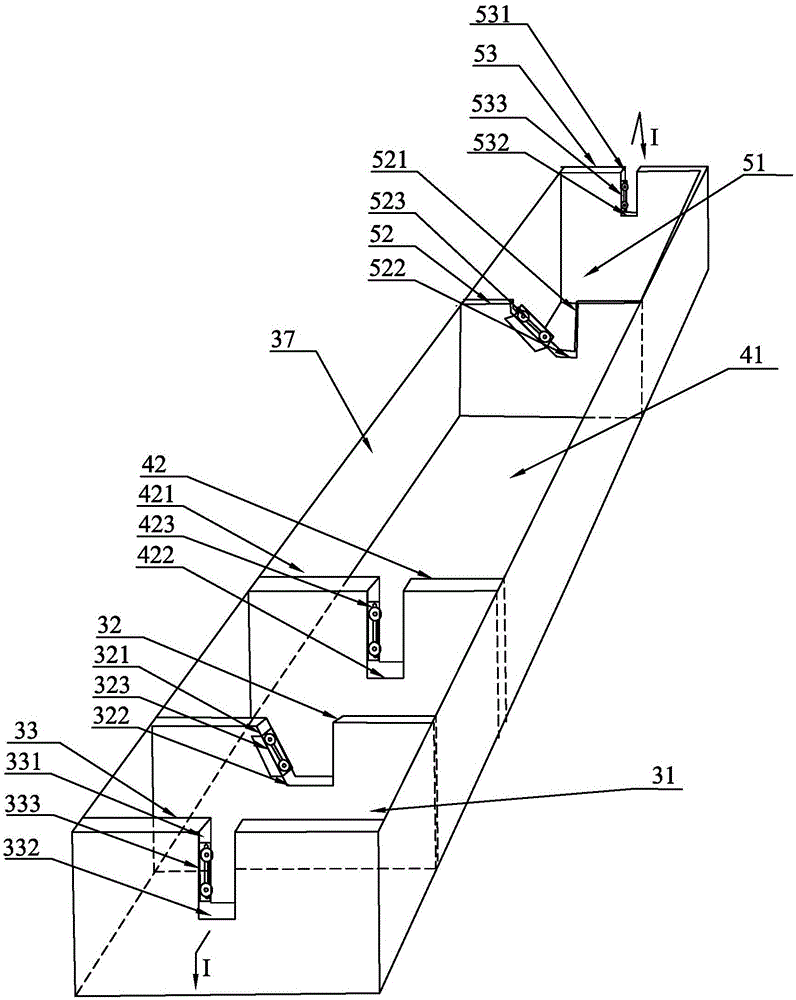

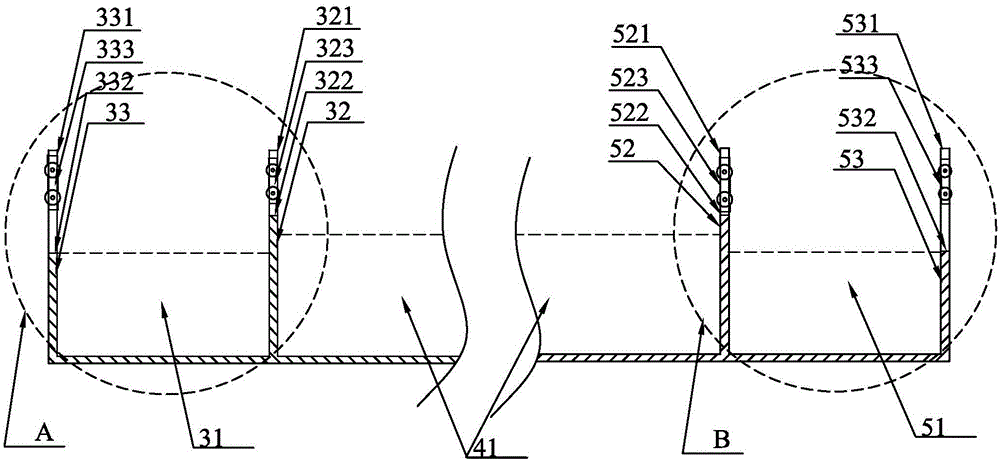

[0071] S10, a rack plating production line 11 is provided; the rack plating production line 11 is consistent with the rack plating production line 11 provided in the first embodiment of the present invention, which includes a conveyor belt 110 and a pre-hanging pre-processing area 20 connected in sequence, a pre-processing turning area 30, The processing reaction area 40 , the post-processing turning area 50 and the post-hanging post-processing area 60 .

[0072] S20, perform hanging, degreasing, activation and pre-plating treatment on the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com