Sealing structure for horizontal plating tank

A technology of sealing structure and plating tank, applied in sealing devices, electrolysis components, electrolysis process, etc., can solve the problem of less plating tank and achieve the effect of simple structure and continuous plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

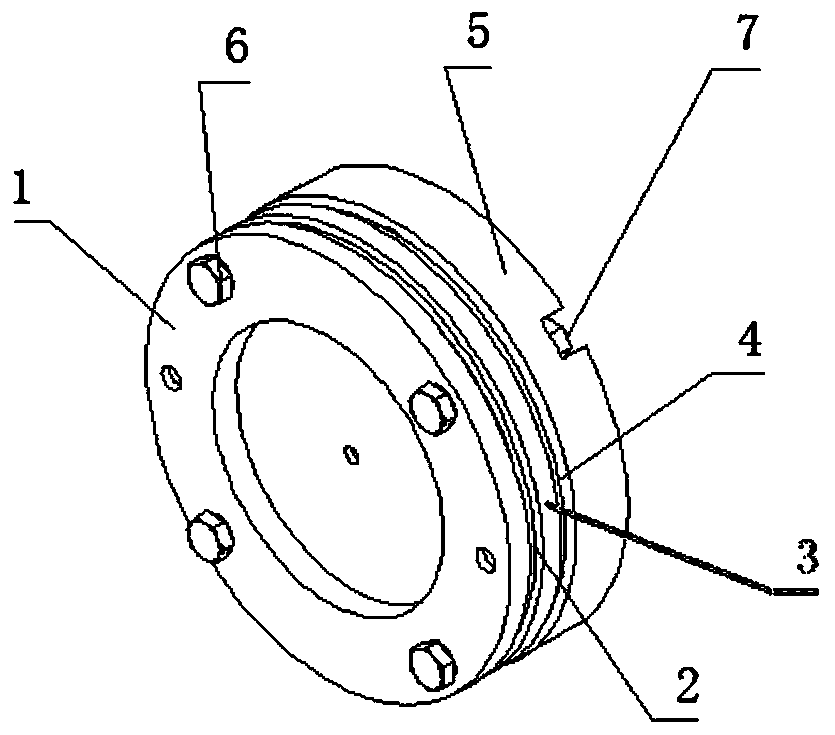

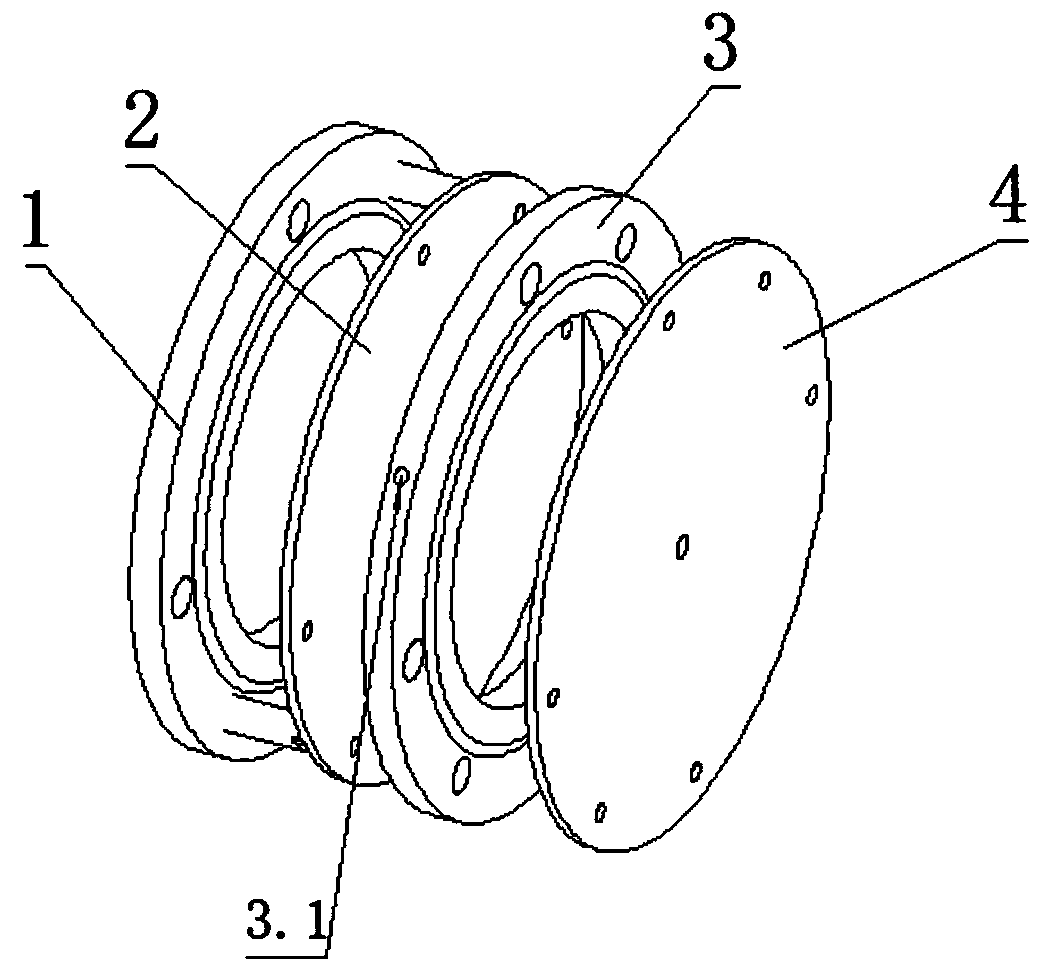

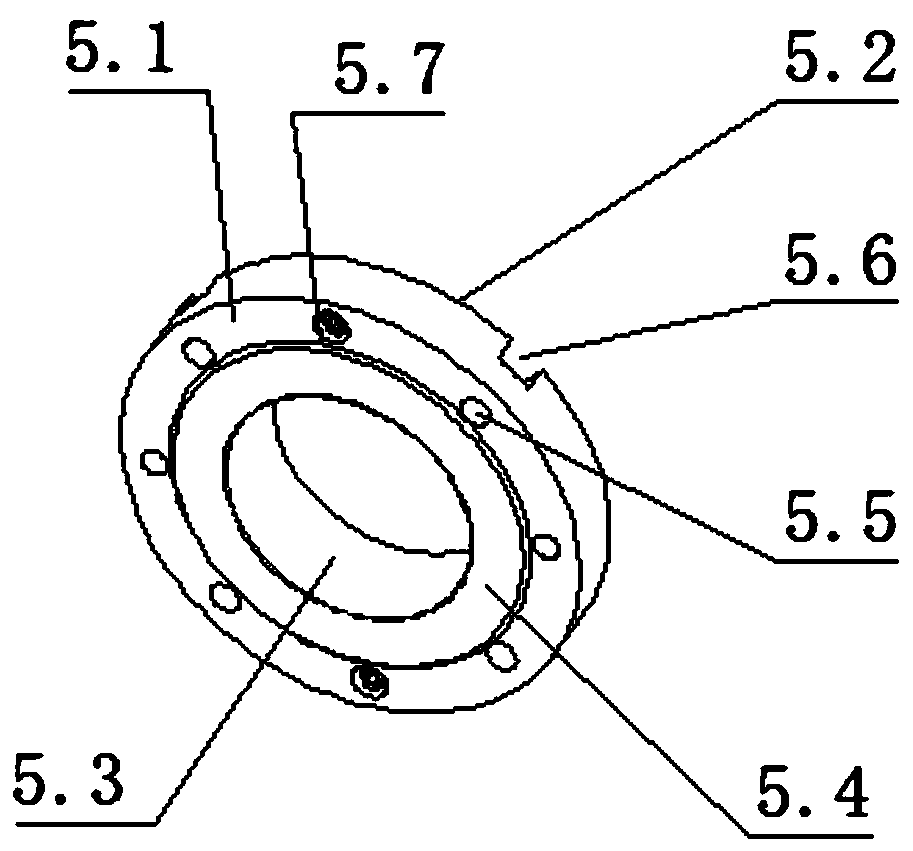

[0017] A sealing structure for horizontal plating tanks (see Figure 1-4 ), including outer sealing flange 1, outer sealing 2, inner sealing flange 3, inner sealing 4 and connecting piece 5; the connecting piece 5 (see image 3 ) comprises an annular connecting ring disk 5.1, the connecting ring disk 5.1 is provided with a fixing hole 5.7 and a bolt connection hole 5.5, the center of the connecting ring disk 5.1 is provided with a ring-shaped convex convex ring disk 5.4, and the outer ring of the connecting ring disk 5.1 is provided with an outer ring The retaining ring 5.2, the edge of the outer retaining ring 5.2 is provided with a bolt installation groove 5.6 which is matched with the bolt connection hole 5.5, the center of the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com