Automatic dropping control system and control method for mobile ore dropping vehicle

A control system and blanking technology, applied in loading/unloading, conveyors, containers, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of solving time-consuming and labor-intensive, realizing unmanned production, and solving process interruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

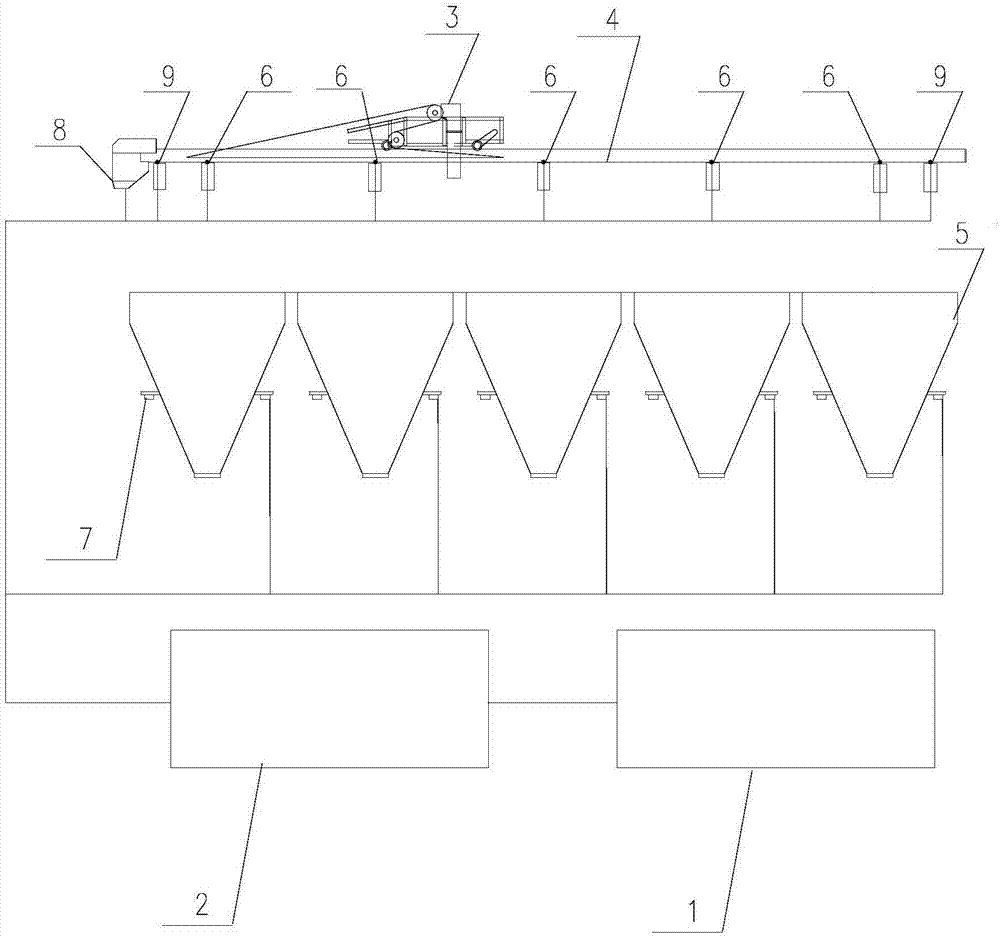

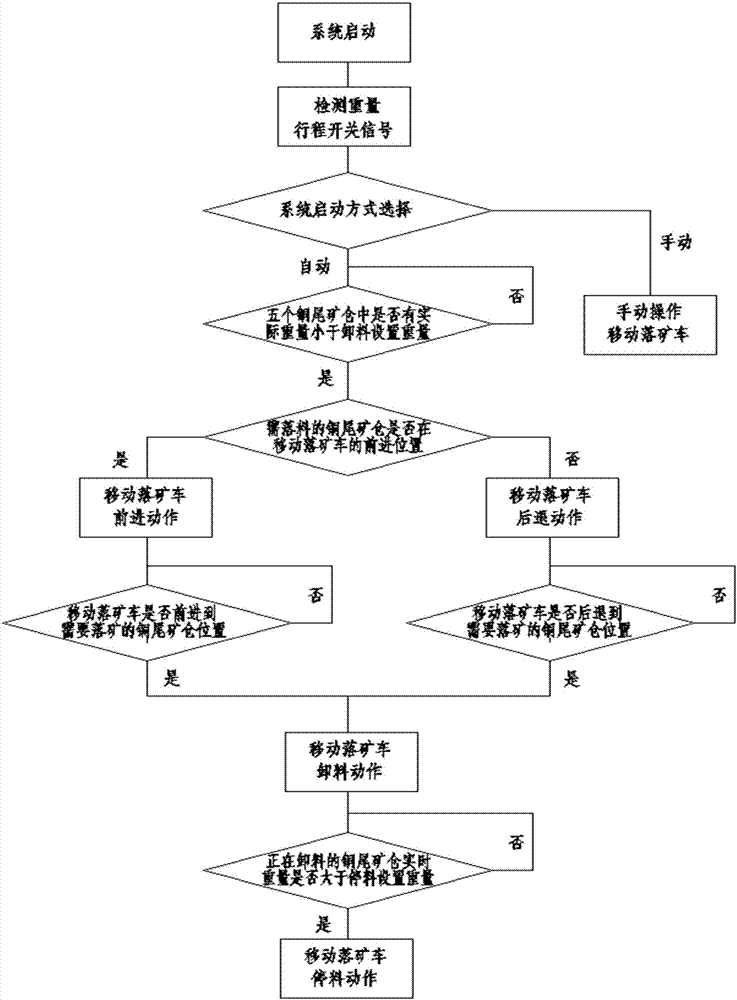

[0029] Such as figure 1 As shown, what the present embodiment enumerates is the blanking of copper tailings, and the automatic blanking control system of the mobile mine dumper includes a human-machine interface (HMI) 1, a programmable logic control system (PLC) 2, and a mobile mine dumper 3 , track 4, ore storage bin 5, travel switch 6, load cell 7, the ore storage bin 5 and the travel switch 6 in the present embodiment are five, and other numbers can also be set as required, but one ore storage bin 5 corresponds to a travel switch 6, five ore storage bins 5 are arranged in a straight line, the track 4 is installed above the ore storage bin 5, the travel switch 6 is installed on the track 4, and one travel switch 6 is located in one ore storage bin Directly above the central position of the upper opening of 5, the distance between adjacent tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com