Composition (floor) slab of steel bar welding orthogonal net rack and concrete

An orthogonal and concrete technology, which is applied in the processing of floors, building materials, structural elements, etc., can solve the problems of overall collapse of cast-in-place slabs, layer-by-layer support and formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

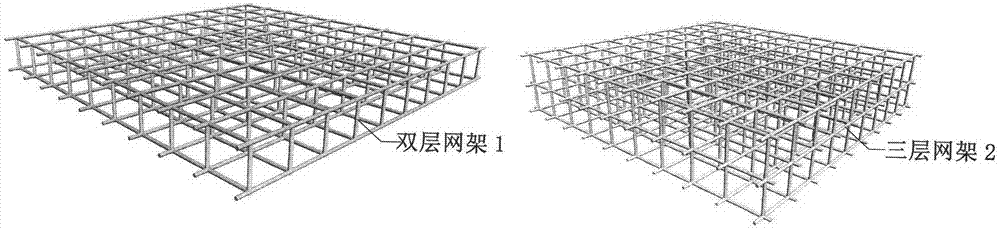

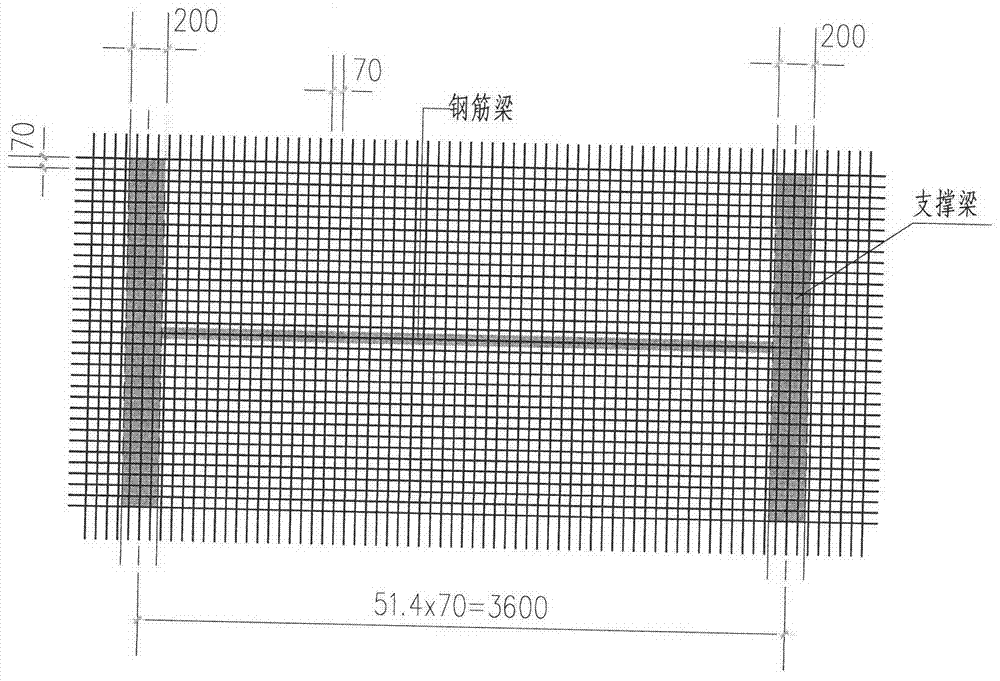

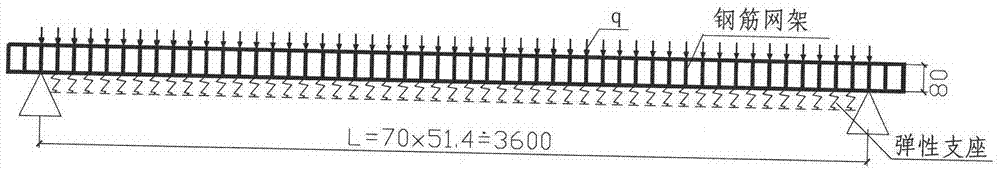

[0044] Specific implementation mode one: combine figure 1 Make a double layer and weld it with Q235Φ6 steel bars. The grid plane size is 70×70mm, and the plane layer height is 80mm. The orthogonal and vertical grid frame 1 is set on the beam, and then the decoration is made of type A and type B with hanging bars. slabs, aerated concrete and other lightweight concrete slabs are fixed on the grid as a permanent formwork. The method of type C is to wrap several layers of steel wire mesh at the bottom of the grid, subject to no leakage of grout, and then pour concrete above C20 without support and template.

specific Embodiment approach 2

[0045] Specific implementation mode two: combination figure 1 , according to the special requirements of the board, it can be made into a three-layer grid frame 2. The diameter of the steel bar can be from Φ6 to Φ10, which is more economical. The grid plane size is preferably from 50×50mm to 120×120mm. The slenderness ratio of the steel bar is ≥150. Set the grid frame on the beam, fix it on the grid frame with hanging bars according to the methods of Type A, Type B, and Type C, and then pour concrete larger than C20 to make a reinforced concrete cast-in-place floor slab that meets special requirements. No braces, no formwork.

specific Embodiment approach 3

[0046] Specific implementation method three: Reinforcement welded orthogonally placed grid frame and concrete composite (floor) slab Use hanging bars to fix the light concrete slab on the grid frame or fix the fireproof board on the grid frame or fix the insulation board on the grid frame In general, concrete greater than C20 is poured in the method of type A and type B. After solidification, it will be a high-quality anti-impact noise floor, or a floor with a high fire resistance level, or a floor with a high insulation level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com