Cutting and stroking device for twisted pair

A technology of twisted pair and wire cutting, which is applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of joint production failure, uneven line, low work efficiency, etc., and achieve simple structure and low manufacturing cost. Low, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

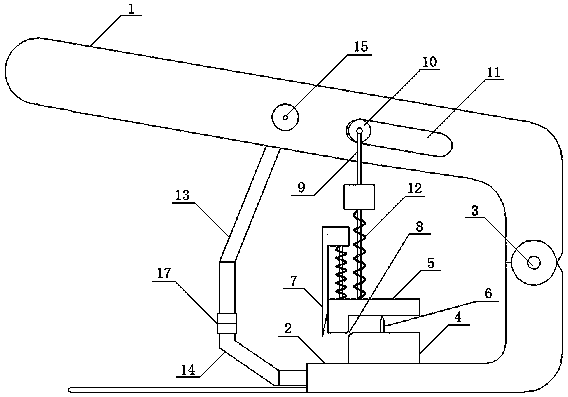

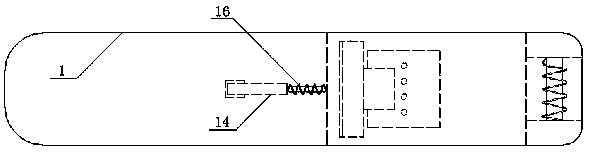

[0012] Such as figure 1 , 2 As shown, the pressing rod 1 of the present invention is connected to the base 2 through a hinge 3 . A line cutting device is arranged between the depression bar and the base, which is composed of a pedestal 4 and an L-shaped pressing plate 5 . The pedestal is provided with four splitting needles 6 arranged apart, and the outer side of the L-shaped pressing plate is provided with a cable cutting knife 7 with the blade facing downward, and the blade of the cutting knife sticks out to the below of the L-shaped pressing plate. The contact portion 8 of the L-shaped pressing plate and the pedestal staggers up and down and left and right by 1mm. The L-shaped pressing plate is connected in the slideway 11 on the depression bar through the connecting rod 9 and the pulley 10. This structure is to ensure that the connecting rod can still maintain a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com