An online moisture detection device and method for a bulk material

A detection device and detection method technology, applied in the measurement device, by removing a certain component weighing, material weighing and other directions, can solve the problem of high labor cost, inability to meet online rapid detection, manual sampling and detection of materials can not meet high yield, Efficient and highly automated production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

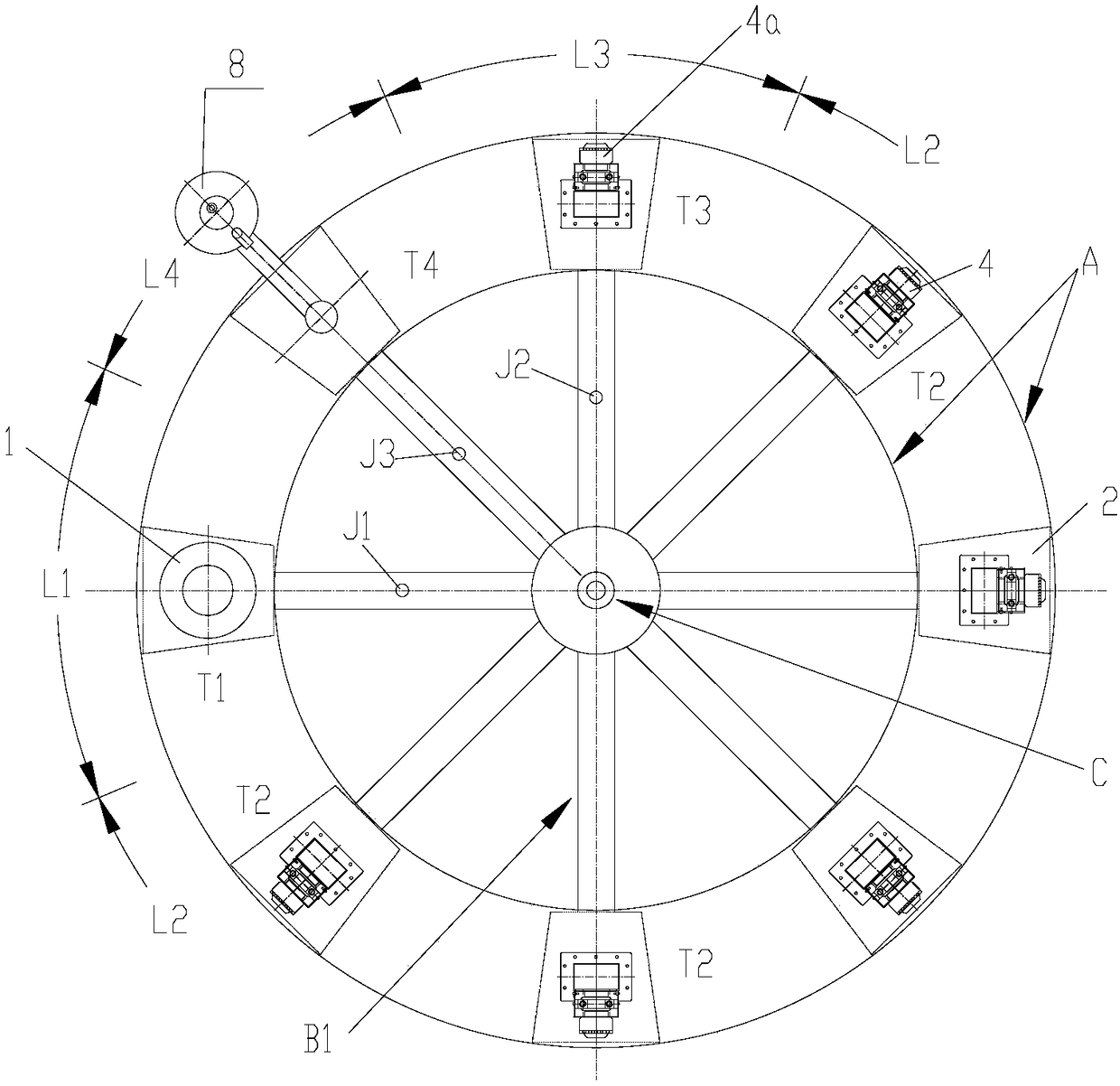

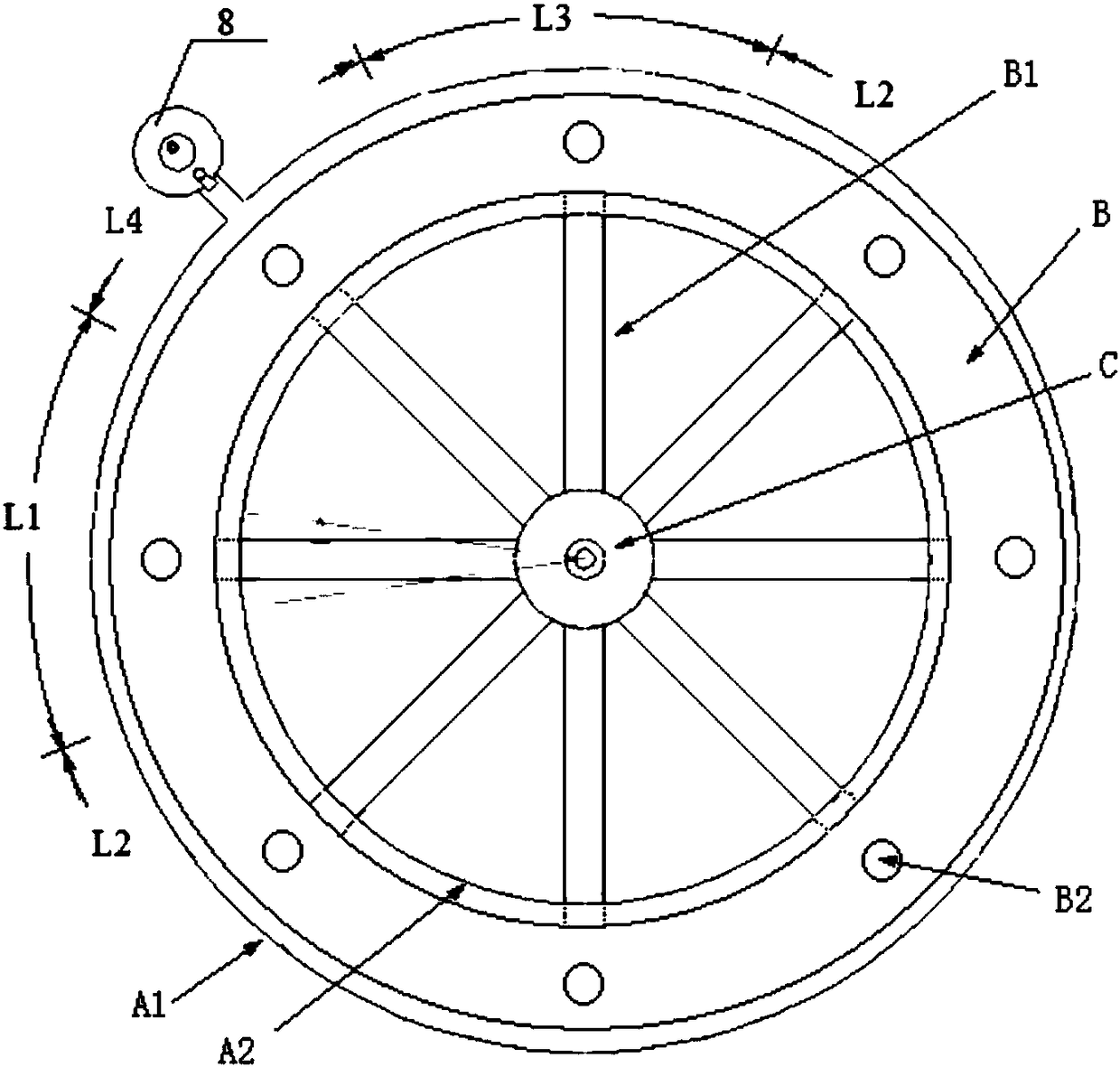

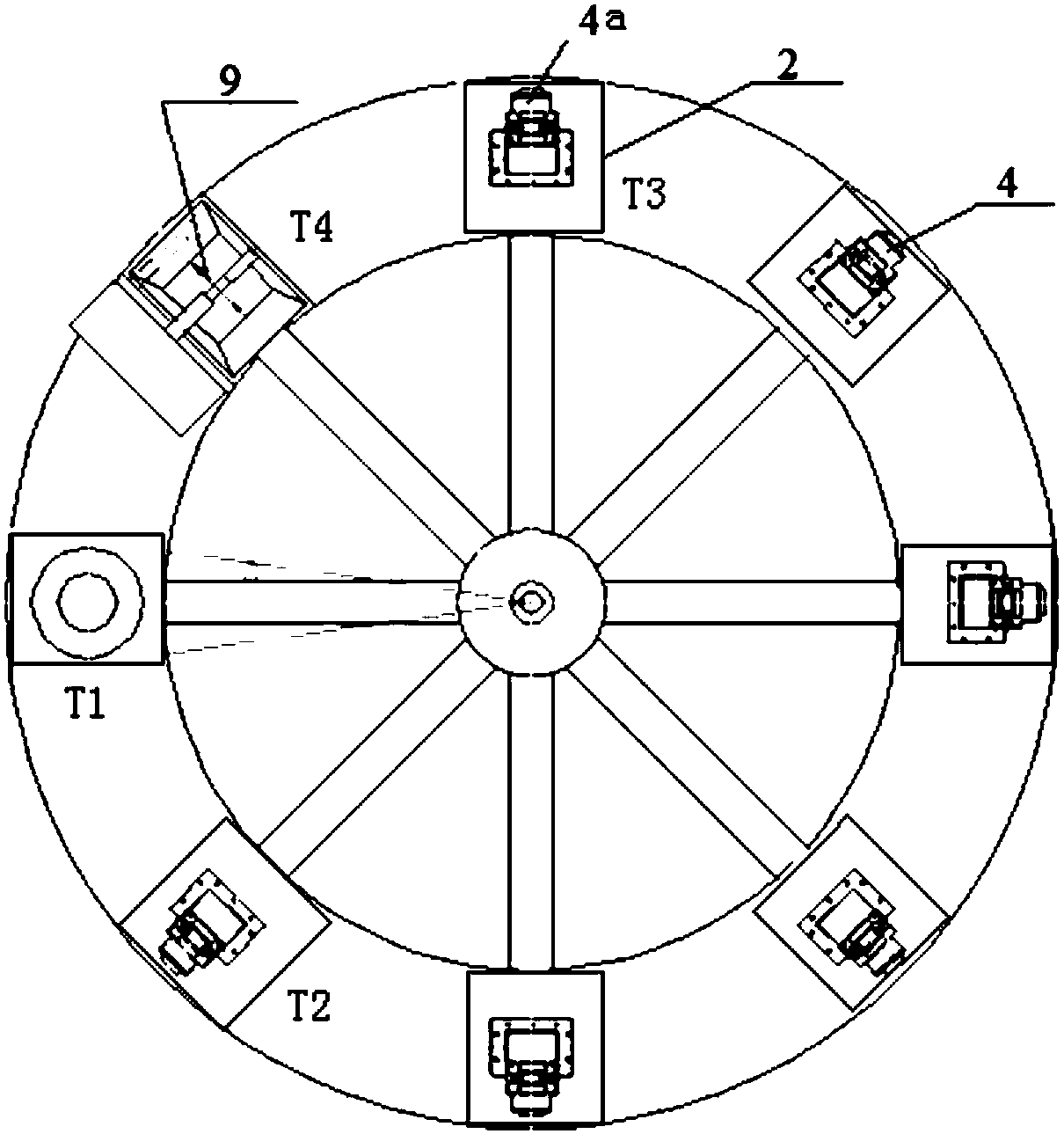

[0140] Such as figure 1 , figure 2 with image 3 , an on-line moisture detection device for bulk materials, the detection device includes a closed-loop annular channel, the annular channel is divided into a first section L1, a second section L2, a third section L3 and a fourth section L4 . The annular passage is made up of an annular cover body A and an annular bottom plate B. The annular bottom plate B is connected with the driving device C through a support rod B1. The annular bottom plate B has a plurality of through holes B2 along the circumference and correspondingly places 8 holes on these through holes B2. 2 charging boxes.

[0141] The plurality of through holes B2 of the annular bottom plate B in the annular channel are distributed on the annular bottom plate B at equal intervals.

[0142] Wherein, the first section L1 is a feeding area, the second section L2 is a microwave drying area, the third section L3 is a detection area, and the fourth section L4 is a dis...

Embodiment 2

[0150] Repeat embodiment 1, only the sampling equipment of this device changes sampling driving device 7 into, as Figure 11 , the sampling driving device 7, the sampling driving device 7 includes a spoon-shaped sampling plane 701 at the front end, a sampling pipeline 702 at the middle end and a sampling driving structure 703 at the end, the sampling driving device 7 is used to grab materials and send them to the hopper 1 .

Embodiment 3

[0152] Repeat Example 1, just as Figure 13 , the discharge device of the device is changed to a purge type discharge device 9. At this time, the forward direction of the charging box 2 has a curved surface with a certain radian, and the discharge port of the purge type discharge device 9 is connected to the existing production site. In the dust removal system, it is convenient for cleaning and dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com