Extractable fire cylinder smoke tube

A fire tube and smoke pipe technology, which is applied in the direction of combustion product treatment, combustion method, exhaust gas device, etc., can solve problems such as troublesome maintenance, damage to the fire tube, scaling of the fire tube, etc., and achieve easy maintenance, safe and convenient use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

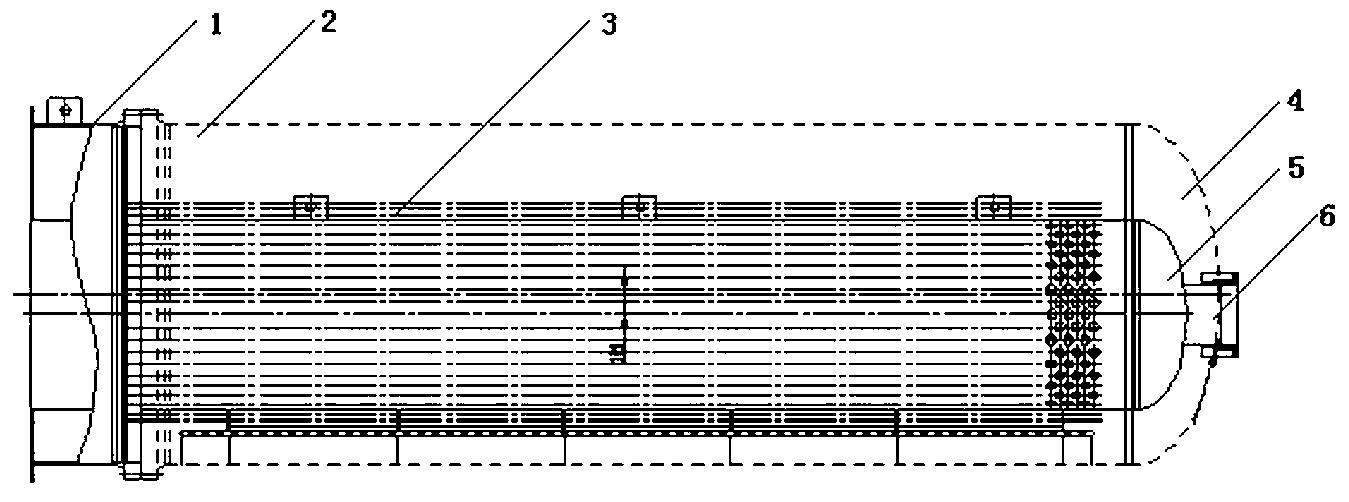

[0010] Drawable fire pipe, including fire pipe box 1, container flange 2, slideway 3, cylinder rear head 4, fire pipe pipe 5, explosion-proof door 6, the heating furnace body has a two-return structure, fire pipe pipe 5 It is integrated with the fire tube smoke box 1, and is connected with the equipment cylinder through the container flange 2. The bottom of the fire tube smoke box 1 is provided with a support, the inside of the fire tube smoke box body 1 is provided with a slideway 3, and the upper part of the fire tube smoke tube 5 is equipped with a For hoisting lugs, the rear part of the fire tube smoke tube 5 is an elliptical head structure with a short section, and the short section and the rear head 4 of the cylinder adopt a stuffing box sealing structure.

[0011] In the above-mentioned extractable fire pipe, the explosion-proof door 6 is bolted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com