Method for treating ageing oil of viscous oil

A treatment method and technology for aged oil, which is applied in the treatment of heavy oil and aged oil, and in the field of aged oil treatment, can solve problems such as unstable operation of crude oil dehydration system, no reference for heavy oil and aged oil, and non-negligible environmental management risks, etc., to achieve Improve the effective storage capacity, avoid the risk of oil loss, and have significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 aging oil demulsifier

[0052] The present embodiment provides a demulsifier for aging oil, which has the following composition:

[0053] Phenol, 0.8%, Styrene, 2.0%, Polyethylene Polyamine, 0.6%, Formaldehyde, 0.8%, Catalyst, 0.75%, Ethylene Oxide, 45.05%, Propylene Oxide, 50%.

[0054] The aging oil demulsifier is prepared according to the following steps:

[0055] Add phenol, styrene, polyethylene polyamine and formaldehyde into the reaction kettle and mix at 120-140°C to obtain the initiator;

[0056] Add the catalyst to the reactor, vacuumize and control the pressure in the reactor below 0.4MPa, slowly add ethylene oxide and propylene oxide at 120-140°C, and react to negative pressure to obtain the aged oil Demulsifier.

[0057] The above-mentioned aged oil demulsifier provided in this example is especially suitable for the demulsification treatment of heavy oil aged oil.

Embodiment 2 3

[0058] Embodiment 2 three-phase decanter centrifuge

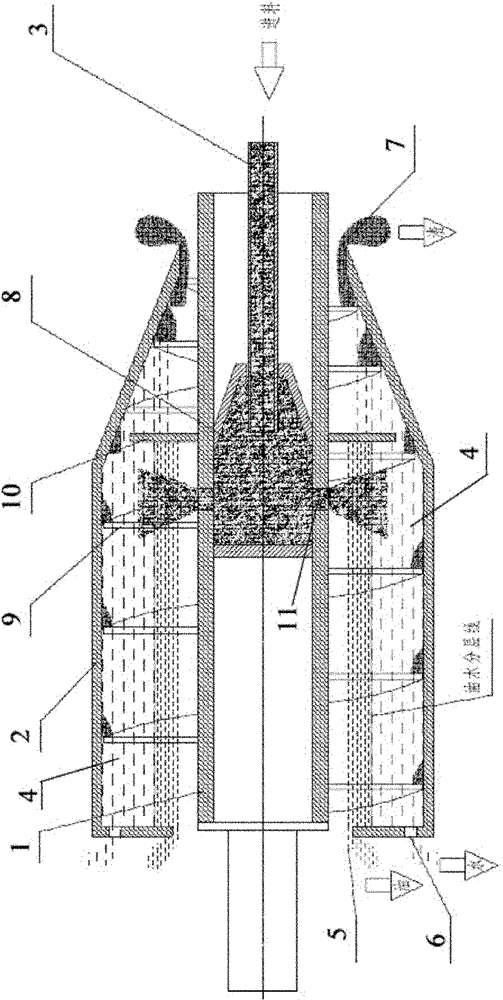

[0059] This embodiment provides a three-phase decanter centrifuge, which includes a differential, a screw propeller 1, a drum 2, a casing, a machine base, a motor and a feed pipe 3, wherein,

[0060] The casing (not shown in the figure) is fixed on the machine base (not shown in the figure), and the setting method of the casing and the machine base can be carried out according to the setting method of the existing centrifuge. The drum 2 is arranged in the casing, and the rotary drum 2 The two ends of the drum 2 are respectively a cylindrical area and a conical area;

[0061] The screw propeller 1 is arranged at the center position inside the drum 2, and a material pool 4 is formed between the inner wall of the drum 2 and the screw propeller 1, and the material pool 4 is provided with an oil outlet at one end of the cylindrical area of the drum 2. The oil outlet 5 and the water outlet 6, the oil outlet 5 is close to the s...

Embodiment 3

[0066] Embodiment 3 aging oil treatment method

[0067] This embodiment provides a method for treating aged oil. The method for treating aged oil is a method for treating aged oil in the cold-combined station of Liaohe Oilfield, and the existing aging oil treatment equipment in the oilfield can be used.

[0068] The method includes the following steps:

[0069] The 20°C ground degassed viscosity of the heavy oil aged oil in the Lengyi joint station is about 80000-150000 cp, and the Lengyi combined heavy oil aged oil (with about 50% water content) is heated to 90-95°C with a heating furnace;

[0070] Add the aged oil demulsifier provided in Example 1 to the heated heavy oil aged oil through a dosing pump, based on the total weight of the thick oil aged oil, the amount of the demulsifier added is 600mg / kg;

[0071] Transport the aged oil of heavy oil with added demulsifier to the buffer settling tank of aged oil, and keep it warm for about 8 hours;

[0072] The heavy oil aged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com