Casting blank length precision measuring device and method

A technology of precise measurement and slab casting, which is applied in the field of casting, can solve problems affecting measurement accuracy, etc., and achieve the effect of improving measurement accuracy, satisfying measurement accuracy, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

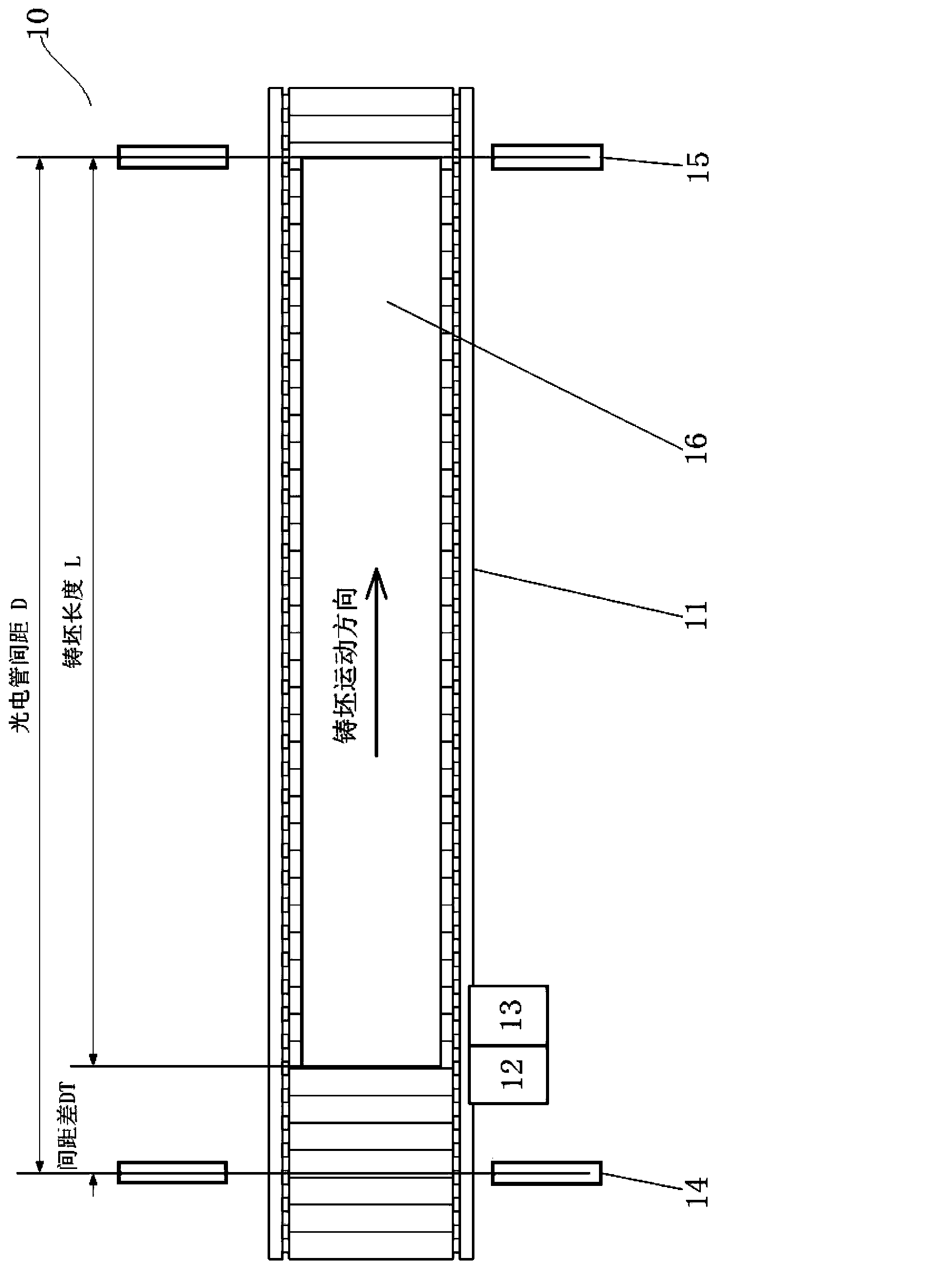

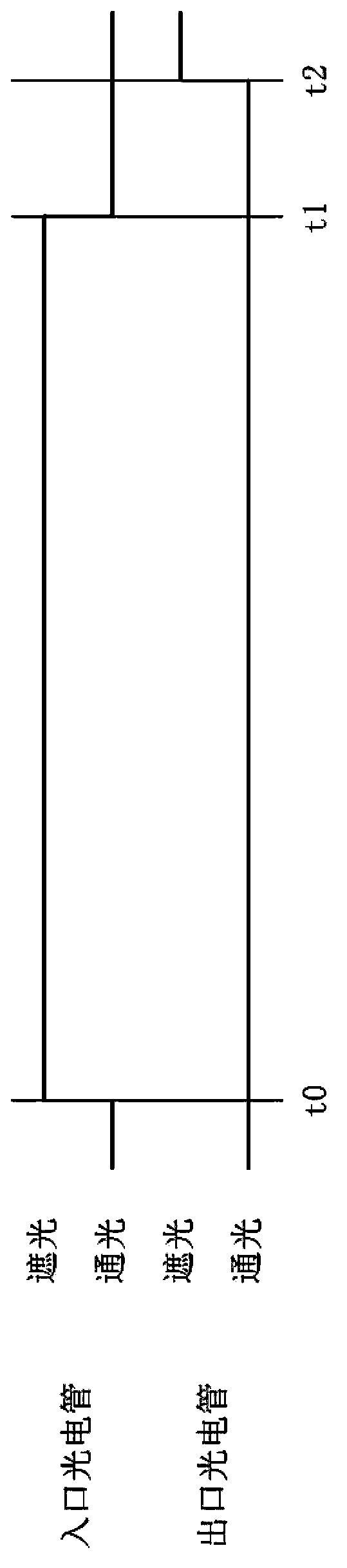

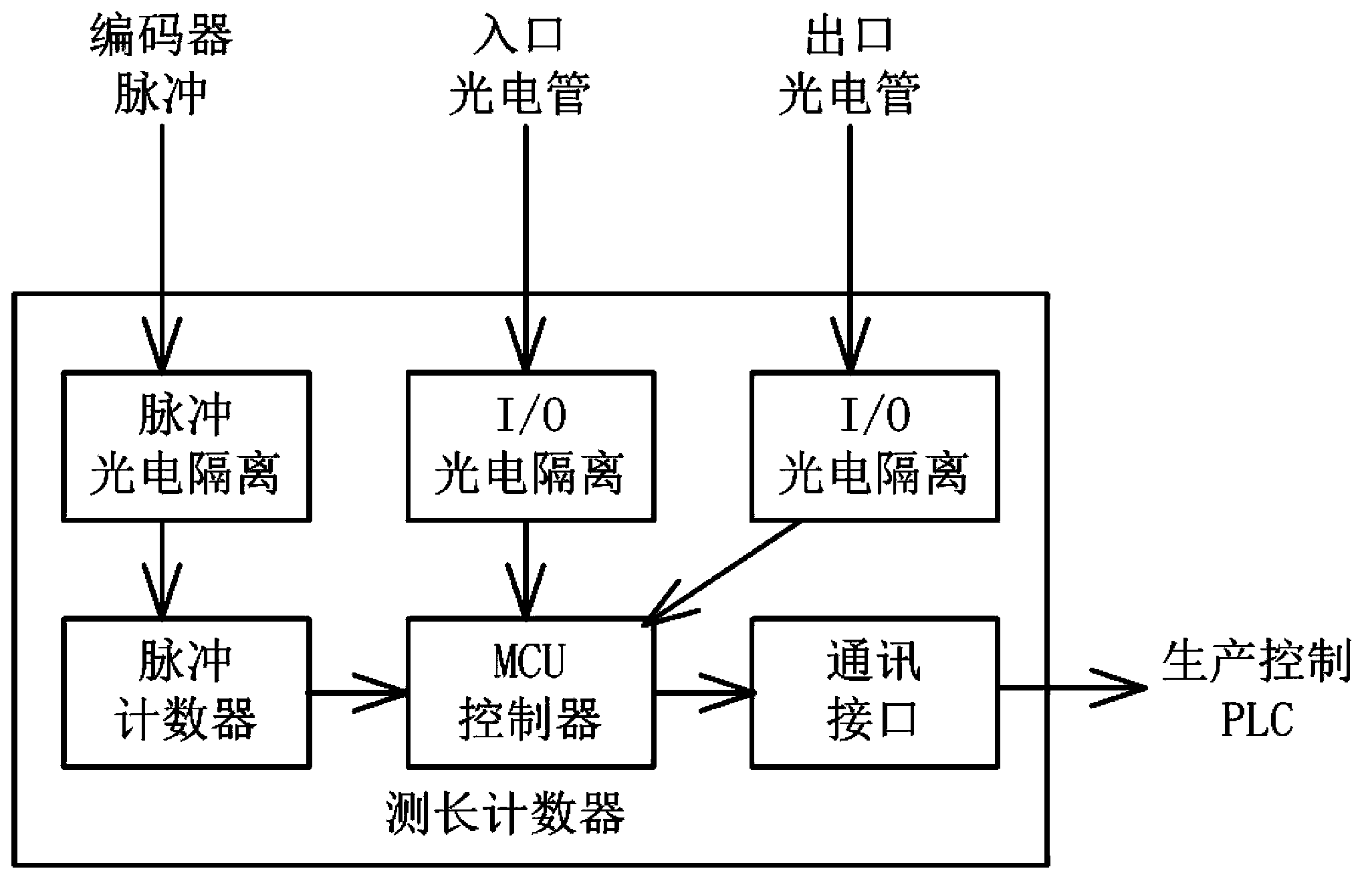

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] The measurement of the length of the slab is very important to the lean production of continuous casting. The traditional length measurement method uses the length measuring roller. When the slab is moving, the length measuring roller is dragged to count the rolling pulses. If the slab jumps, the slab and the measurement If the long roller is in poor contact, the length measuring roller cannot be dragged normally, and the measurement result will be incorrect. And the longer the slab, the greater the probability of the slab jumping, and the greater the error.

[0027] In the production process of casting slabs, starting from cutting, it usually needs to go through multiple processes such as deburring, spray printing, casting slab inspection, traversing trolley transportation, and off-line. Each process usually has 1 set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com